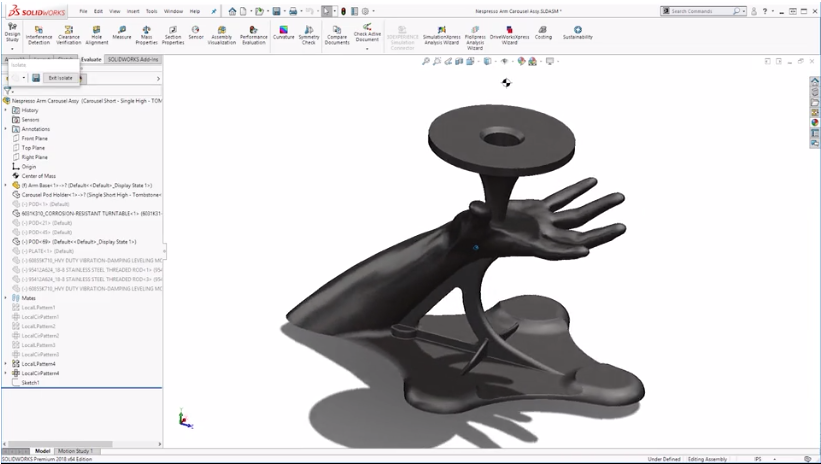

In this article, we go into more details about the process of importing organic shapes into CAD. We will explain how we created a custom coffee pod holder by scanning a human hand and including it in the CAD design.

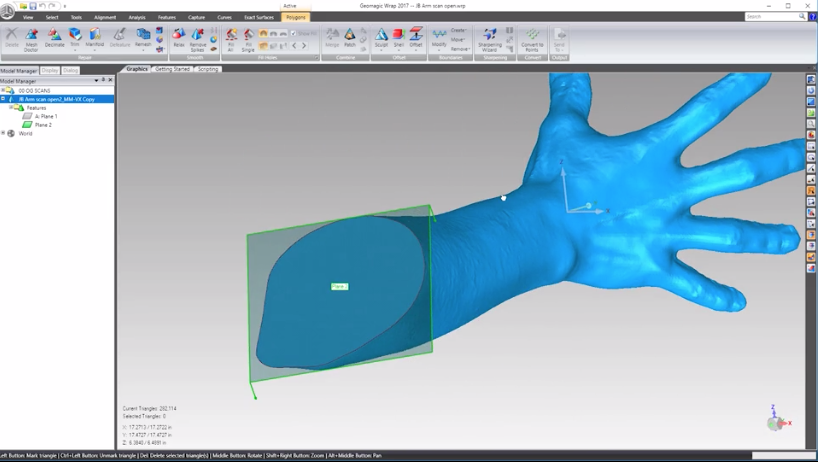

The first step involved capturing the geometry. There are many different 3D scanners out, all of which vary in accuracy, resolution, and light technologies. In order to facilitate the scanning of the hand, we used a structured white light scanner, which does not require positioning targets.

Once the data was acquired, the second task involved data clean up. Using mesh editing software like Geomagic Wrap, we were able to easily post-process the data, optimize the mesh quality, and thicken it, and then align it to a World Coordinate System.

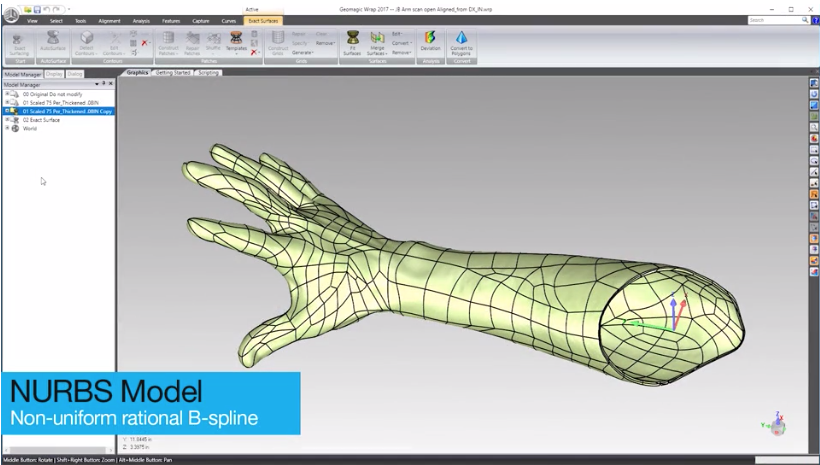

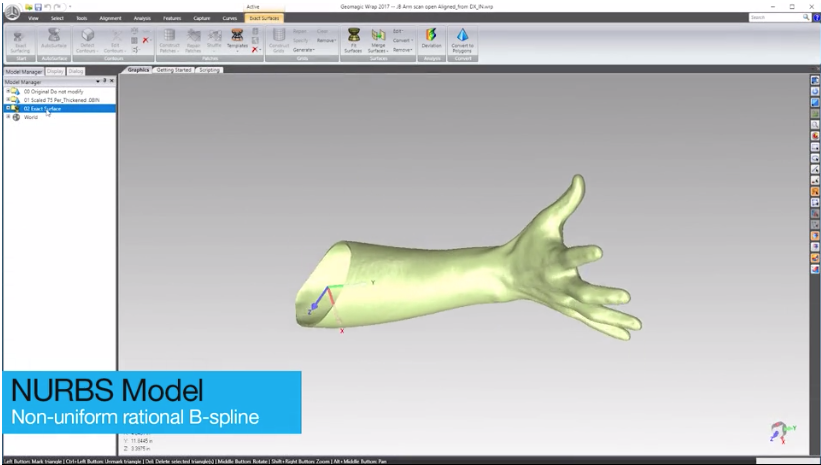

We needed to ensure that we had a water-tight mesh and then we needed to take that data and convert it to something manageable and useable in CAD. Instead of exporting each of the thousands or millions of triangles into CAD, we used Geomagic Wrap to create B-Rep surfaces, group the triangles into surface patches, and create a solid body.

At this point, we exported this body as a non-parametric neutral CAD file, like a STEP file or a Parasolid.

Please note that capturing your organic shape through 3D scanning is only the first step. For it to be useable and manageable for CAD an intermediate step is required and that is creating B-Rep surface patches to form that CAD solid.

Stay tuned to future blog posts where we will show you how easily this STEP file of the hand can transfer into CAD, as well as some of the challenges that we face while creating the design. Please be sure to sign up for our 2 Minute Tuesday video series to receive tips and tricks like this one in video form every week. More info at the button below.

Leave A Comment