Experience improved model arrangement on the virtual build plate, powerful new engine plugins, and remarkable productivity improvements for UltiMaker S series printers in the newest version of Cura!

Ultimaker S series 3D printers can now print at up to twice the speed

UltiMaker is always on a mission to refine their printers. This includes not only their latest machines but also those already in the hands of the users. This Cura release contains one of the best examples of their dedication to continuous improvement with up to double the 3D printing productivity for everyone using our S series printers together with UltiMaker materials.

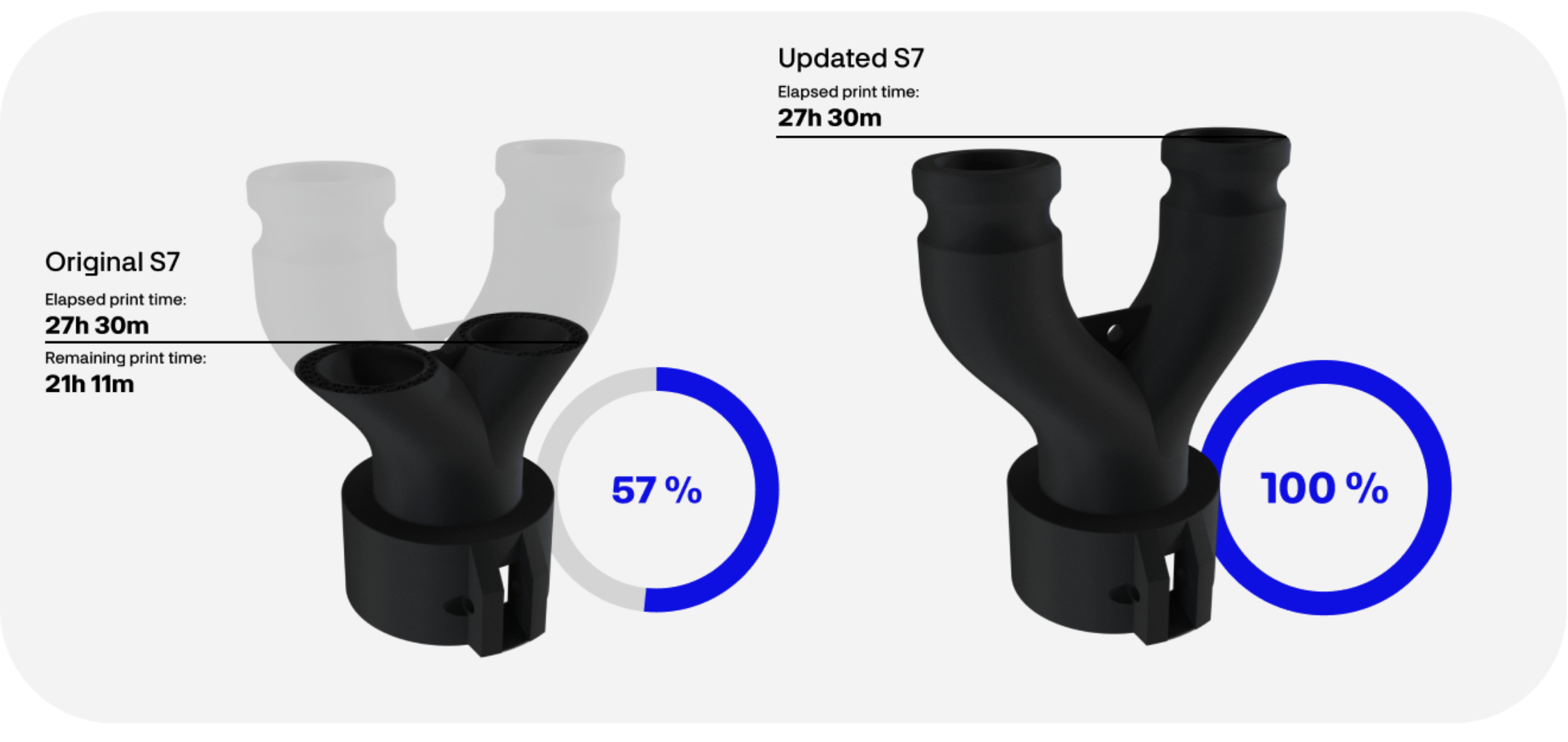

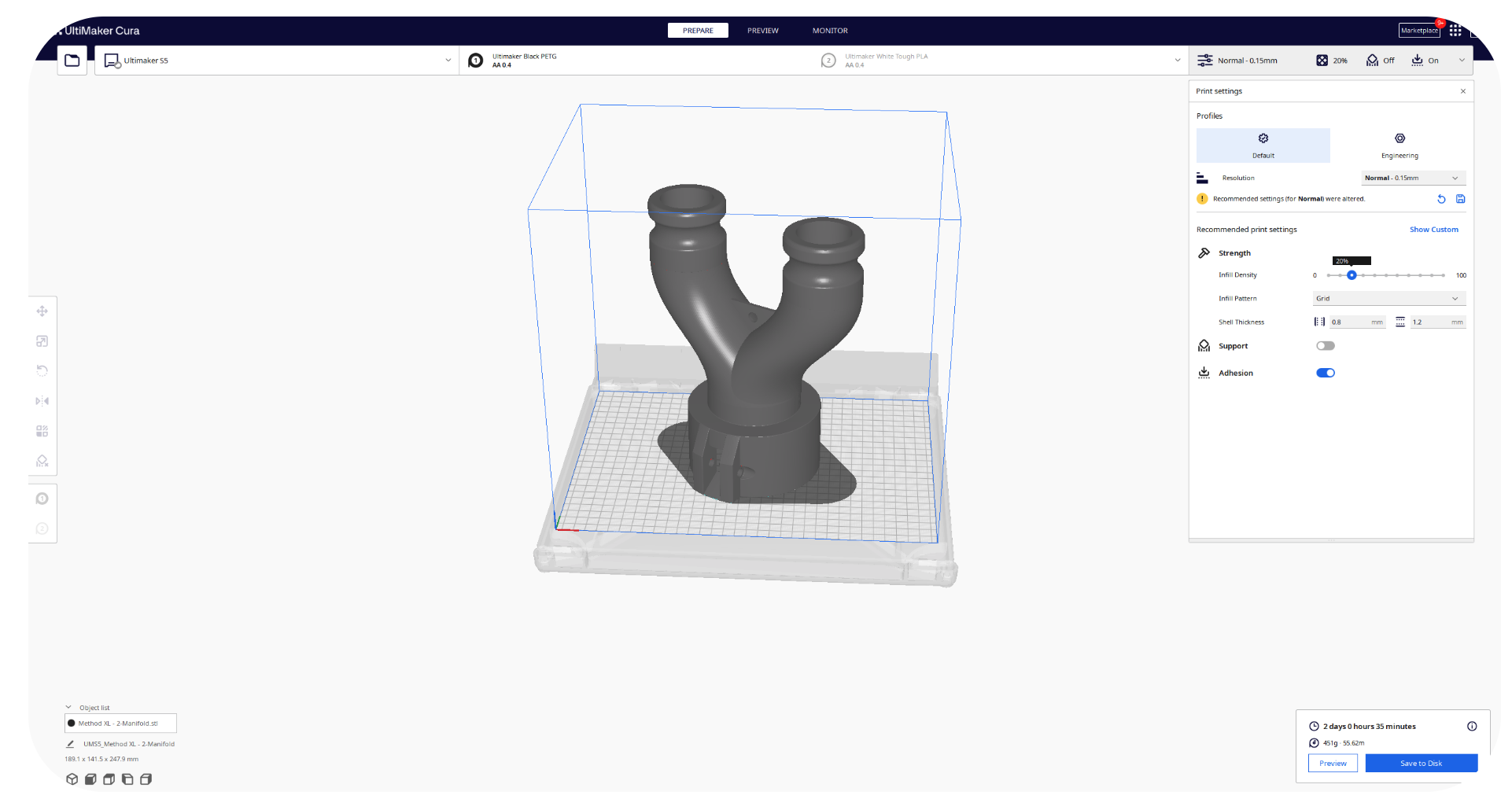

While the raw speed of the S series printers has increased, it should be noted that it is the overall productivity of their printers that has been improved. They have been able to realize this speed increase without reducing print quality or increasing failure rates. This is a huge achievement! Whether you’re using an S7 you bought today or an S5 you bought years ago, you can now print parts in up to half the time, without any reduction in reliability or quality. For instance, in the previous Cura 5.4 release, printing a part in PETG on an S5 with an AA 0.4 mm print core would have taken 2 days and 35 minutes:

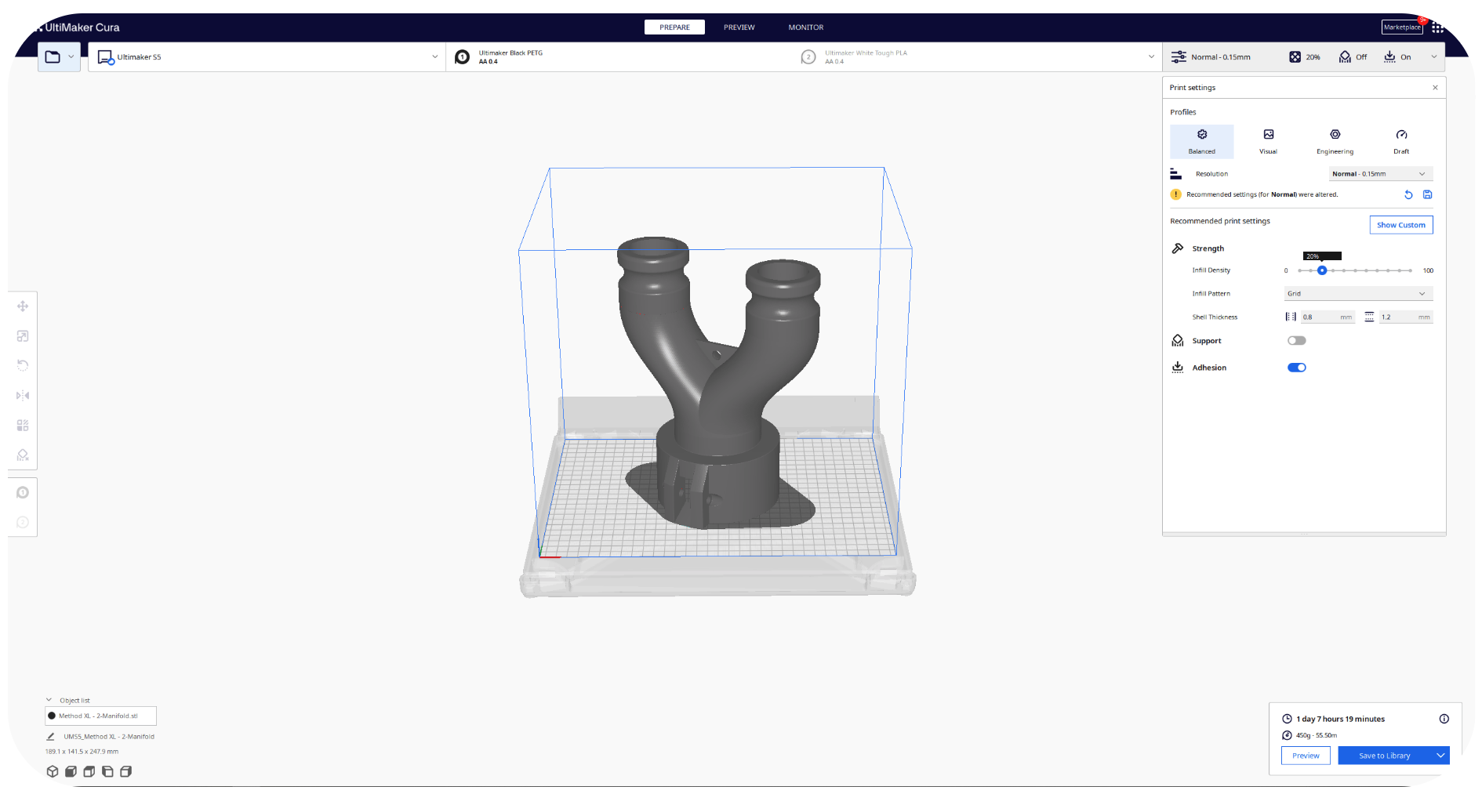

But in Cura 5.5 it will take just 1 day 7 hours and 19 minutes using the same material, extruder, and printer:

Historically, these types of advancements have been the outcome of rigorous testing and fine-tuning of the print profiles. This time they also introduced new features that harness the full potential of our printers. A few prominent additions include:

Optimized print speeds for different line types

Outer walls, inner walls, and supports are all printed at different speeds. UlitMaker has optimized the print speed for these and other line types, while also adjusting the acceleration and deceleration behavior when moving between line types. As a result, they are now able to print internal structures faster without reducing the visual quality or mechanical properties of your part.

Smooth internal wall pathing

Previously the inside of walls was printed using a diagonal pattern that resulted in the print head performing a jittery zig-zag motion during printing. This has been changed so that the inside of walls now print using long smooth lines which enables the print head to reach higher speeds.

Prevent infill crossing close to walls

Tweaks have been made so that infill no longer overlaps near to external walls. Overlapping infill near walls can cause artifacts on the surface of your print, this change prevents those artifacts and also reduces print head travel, increasing print speeds.

For more information on Ulimaker 3D printers, please click below.

Leave A Comment