Batch Processing in Control X Professional

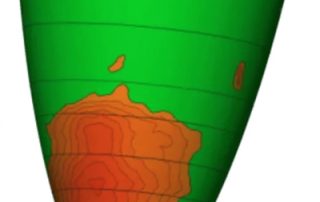

Batch Processing in Control X Professional This month, we continue to explore the Control X Professional Automation tools. Last month, we took a look at the Airfoil Analysis tool. This month, we focus on Batch Processing. Batch processing enables the user to create an inspection plan using a nominal CAD model and can then automatically assign the same inspection criteria to any number of scans, located on the user’s network. [...]