This post will cover some of the fundamental concepts in 3D printing: accuracy, precision, and tolerance. Understanding these key concepts and the differences between them is necessary for achieving the level of performance you desire when evaluating any 3D printing technology. First and foremost, you need to understand that just because a printer lists a high-resolution in a spec-sheet, it does not mean that your parts will be accurate or precise. This is a common misconception and will be covered in a future blog post.

Let’s begin by defining the three terms (accuracy, precision, and tolerance) and then we will use common examples to help you understand each.

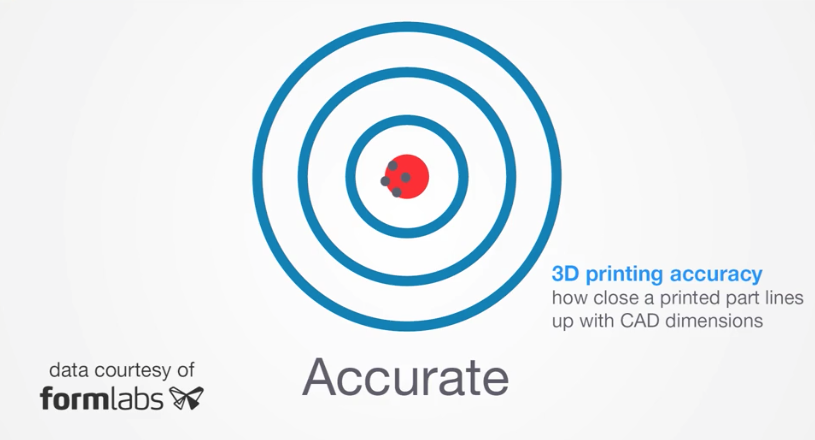

Accuracy is how close a measurement is to true-value. A common example is a target where the true-value is the bullseye. The closer you are to the bullseye, the more accurate you are. In 3D printing, the true-value equals the dimensions of your CAD model and how close the 3D print lines up with those dimensions.

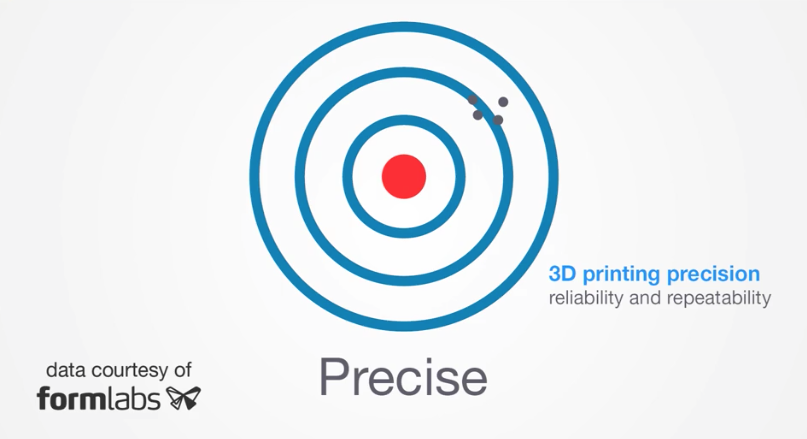

Precision measures the repeatability or consistency. For example, your shots on a target could be hitting near the same spot every time but not necessarily on the bullseye. In 3D printing, this translates into reliability, i.e. will your printer produce the same result every time?

Lastly, tolerance determines how accurate or precise you need to be and is defined by you or your application. In other words; what is the acceptable range in your measurements? For example, a flight-ready aircraft part will most likely require a tighter tolerance than a simple plastic enclosure. You should realize that achieving and holding tighter tolerances will mean higher costs due to manufacturing and quality assurance.

There are other elements that affect accuracy and precision. Achieving successful results will require your attention to the entire process and not just the printer hardware. For example, materials have different shrinkage rates and some processes require post-curing or support-removal, which might introduce warpage. This may not be important if your goal is to create conceptual models but need to be considered if you are creating parts for final use.

In Cimquest’s 20-year journey with 3D printing, one of the most important things that we learned is that there is no perfect 3D printer. This is why we represent a diverse portfolio of 3D printing technologies that cover a wide range of needs and applications.

For more information on our full line of 3D printers, please click the button below.

Leave A Comment