Performing a Datum Alignment using Control X

Performing a Datum Alignment using Control X Before the scan of a manufactured part can be inspected using Control X, it must first be aligned to its nominal CAD model. The nominal CAD model represents the ‘perfect’ shape. Once aligned, all of the Control X inspection functions, including Color maps, Whisker plots, 2D and 3D dimensions, Geometry Deviation, 2D Twist Analysis and more can all take place. Consider the water pump cover shown below, prior to alignment. The datums to be used for alignment can all be found on the mating side of the cover. The Primary Datum, Datum A, is the mating face on the underside of the cover. Datum B is the large cylinder and datum C is the small hole that will clock the alignment. The datum Alignment tool makes simple work of aligning the scan to the nominal CAD model by matching up the analytic features that were selected as datums on the nominal CAD model. The software can distinguish the matching features on the scan and perform the alignment with three simple clicks on each datum surface. After alignment, the software returns any alignment error for the Primary, Secondary and Tertiary datums. Once aligned, any [...]

How Flat is Flat Enough? – Verifying Flatness of a CNC Face-Milled Surface

Let’s say that this water pump cover needs to lie flat against its mating surface to within a specific GD&T Flatness Callout. We’ve seen, in the past, that Control X can check for GD&T Callout information and return pass/fail conditions. But we can also use Control X to determine the amount that a part is in or out of a ‘Flatness’ spec by turning on a localized color map that we call a ‘Fitting Deviation’. Let’s consider the flat (blue) surface on the water pump cover and ask Control X to check Flatness of the face to .040”. We see that the Flatness of the face is well within the Flatness tolerance callout. The actual flatness is actually coming out at .0176”. Since the Flatness callout displays a total tolerance value, we can turn on the +/- values to display the Max and Min values. Next, to really examine our surface of interest, we turn on the Fitting Deviation, color mapping tool and can get a much better sense as to exactly what is happening to the face during the face milling operation. Understanding the color map can be extremely helpful for optimizing your toolpath. Below, we notice that the [...]

Special Offer: 3D Printer Demo Units Available!

Special Offer: 3D Printer Demo Units Available! At Cimquest, we are committed to providing you with the latest advancements in 3D printing technology. To make space for our new models, we are offering several demo units of our 3D printers at unbeatable prices. This is a fantastic opportunity for anyone looking to enhance their 3D printing capabilities with high-quality machines. Formlabs Form 3L Demo Unit To make room for the new Formlabs Form 4L, we are offering our Formlabs Form 3L demo unit for sale. The Form 3L has been a reliable and efficient machine, consistently delivering high-quality prints with exceptional performance. Key features include: Large Build Volume: Ideal for large prototypes and detailed models. Intuitive Workflow: User-friendly operation with automatic resin dispensing and simple print preparation software. High-Quality Prints: Produces smooth surface finishes and fine details. UltiMaker S7 Demo Unit We are also offering our UltiMaker S7 demo unit for sale to make room for the brand new UltiMaker S8 Pro. The UltiMaker S7 is known for its versatility and precision, making it a favorite among professionals. Key features include: Advanced Print Capabilities: Supports a wide range of materials and complex geometries. Reliable Performance: Consistent and accurate prints with minimal downtime. User-Friendly [...]

New Tools for Safer, Cleaner, and Smarter Metal 3D Printing: Introducing the Dual Glovebox and XMSieve

Managing metal powders in 3D printing environments just got a serious upgrade. Whether you’re focused on efficiency, safety, or print quality, these two new solutions from Xact Metal are designed to elevate your workflow. 🔧 Dual Glovebox: Smarter Powder Control Starts Here Replacing the older single-glovebox design, the new Dual Glovebox offers a major leap in functionality, ergonomics, and safety. Here’s what makes it stand out: Spacious Interior: A wide glovebox door provides easier access for handling powder and tools inside the chamber. Ergonomic Viewing Window: A large, centered viewing window gives operators clear visibility into the build chamber for more accurate and confident handling. Built-in Storage: Internal storage space keeps essential powder-handling tools and powder bottles within easy reach. Entry Port for Powder Addition: Powder can be added without opening the main printer door—especially valuable for oxygen-sensitive materials. The chamber can be purged before loading, maintaining a controlled environment. Safety Interlock System: To protect users, the system disables the laser and blower motor when the outer door is open. 🧪 XMSieve: Clean, Safe, and Efficient Powder Reclamation The XMSieve is purpose-built for non-reactive metal powders, allowing for quick, safe, and hands-free sieving. It [...]

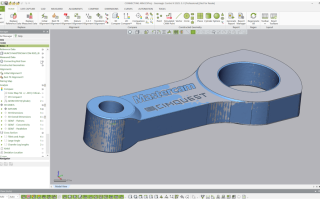

Batch Processing – Unmanned Inspections

We’ve seen how to inspect the scan of a single, manufactured part against an inspection plan generated using a nominal CAD model. But what if we have many manufactured part scans to inspect against the same inspection plan, using the same nominal CAD model. That’s where Batch Processing comes in. The exact same inspection process can be reused as many times as needed and no human intervention is required. Once the batch processing routine is complete, you will have date and time-stamped, serialized inspection reports for each unique part scan. The first step is to create the complete inspection model against the nominal CAD model and perhaps inserting the very first scan to verify alignment, data measurements and output to ensure everything that needs to be inspected is setup properly. The Batch Inspection menu is quite simple to work with… We first select all scans that need to be inspected. Select the Add Files and Browse to the folder where the scans of all the connecting arms are. Next, if there are multiple Results files defined in the Control X model, select the one you’d like to use for this inspection. Next, select the desired Output Options [...]

Meet the Formlabs 4L – Large-Format 3D Printing, Redefined

In the rapidly evolving world of 3D printing, Formlabs has consistently positioned itself at the forefront of innovation. Their latest offering, the Form 4L, exemplifies this commitment by delivering large-format 3D printing capabilities without compromising on precision or reliability. A recent YouTube Short by Cimquest provides a concise visual overview of the Form 4L in action, highlighting its impressive features and applications. Key Features of the Formlabs 4L: Large Build Volume: The Form 4L boasts a substantial build volume, allowing for the creation of larger parts or multiple smaller components in a single print run. This scalability is particularly beneficial for industries requiring rapid prototyping or the production of sizable end-use parts. High Resolution: Despite its larger size, the Form 4L maintains the high-resolution printing that Formlabs is known for, ensuring detailed and accurate prints suitable for both functional prototypes and intricate designs. User-Friendly Interface: Designed with the user in mind, the Form 4L features an intuitive interface that simplifies the printing process, making it accessible to both seasoned professionals and newcomers to 3D printing. Material Versatility: Compatible with a wide range of Formlabs resins, the Form 4L offers versatility across various applications, from engineering and manufacturing to healthcare and [...]