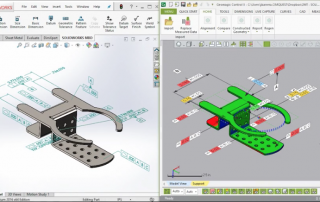

Using SolidWorks DimXpert for Final Inspection

SOLIDWORKS and Control X work really well together in the 3D part inspection world. SOLIDWORKS is one of the leading CAD tools in today’s design and manufacturing world. One of its advantages is that it offers you the opportunity to create a 3D annotated model. This can include things such as explicitly-specified dimensions, tolerances, 3D GD&T, surface texture symbols, finish requirements, and so on. This 3D annotated model is then used to manufacture the part, as well as provides the needed criteria to inspect the part. A part can contain anywhere from several dozen annotations, to several hundred! Wouldn’t it be great to repurpose these annotations, and import them directly into the inspection software, as opposed to recreating all of them one by one? Well, one of the inspection softwares that have this ability is Geomagic Control X. The first step is to add all of the 3D annotations directly to your 3D model. This is a pretty simple process in CAD. Once this is complete, you can open up Geomgagic Control X and use the PMI Wizard to import the 3D annotated model. All of the explicit dimensions and GD&T information will come through with no errors. The last step would be to [...]

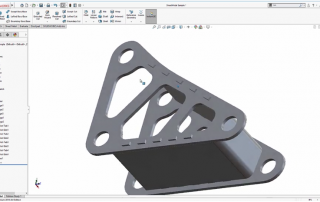

SolidWorks 2018 Tab and Slot

There’s a new feature in SolidWorks 2018 called Tab and Slot that helps you to create a design to interlock two parts, whether in the context of an assembly or multiple bodies. Rather than doing it the traditional way, with several sketches and features, you can now use this new feature in SolidWorks 2018 to get it done much easier. In the image above, we have a box and a lid which we want to interlock with intermittent tabs and slots. To access the new feature that will assist you with this, you go to Insert > Sheet Metal > Tab and Slot. Just as a note, although this new feature is found in the Sheet Metal menus, it can just as well be used in not sheet-metal applications. In the Property Manager, start by selecting an edge for the tabs and corresponding face for the slots. Then, under Spacing, you can set the spacing and number of instances. Under Tabs, set the length, thickness, height, and edge type. Last, you can set any clearances or offsets that you need for the design to be functional. The preview show above signifies that you parameters were input correctly. Click OK and you have an [...]

HP Accelerates the Path to Industrial 3D Manufacturing

HP Jet Fusion 32 4200 printers 3D printing is one of the most disruptive technologies of our time, spearheading a new 4th Industrial Revolution that will radically change the way we conceive, design, produce, distribute, and consume pretty much everything. But until now, 3D printing hasn’t been a viable means of large-scale industrial manufacturing (think big factories) because of prohibitively expensive production costs and limited technology. In order to realize HP’s vision of digitally transforming the $12 trillion global manufacturing industry, the economics of 3D printing needed to be completely rewritten. Recently, HP announced that it has smashed that economic barrier and paved the way for cost-effective, industrial-scale 3D manufacturing with the new Jet Fusion 3D 4210 Printing Solution. The new solution increases production volume for HP Jet Fusion 3D printers by enabling continuous operation, greater overall system efficiency, and the ability handle larger quantities of 3D printing materials, while significantly lowering production costs with reduced pricing on HP’s 3D materials and shared service contracts. When put together with HP’s industry-leading Multi Jet Fusion technology, those enhancements double the existing “break-even point” at which 3D printing remains cost-effective to an unprecedented 110,000 parts, and drastically reduces the cost-per-part, up to 65% [...]

The Cimquest Manufacturing Lab

Cimquest was founded in 1990 as a reseller of CAM & CAD software and soon became a premier training facility. At times we heard our customers struggle with applying new tooling and equipment with the latest Mastercam toolpaths and we wanted to address this issues. We began to build partnerships with tooling, fixturing, and machine tool companies to teach how all these components work together. Shortly after these partnerships started the vision of the lab began. We wanted to develop a lab that is a collaboration of our partners who teach the applications of the latest manufacturing technology – a lab with a team of instructors made up of experienced machinists, tool and mold makers, and engineers. When these folks are not teaching or solving customers problems, they use this lab to learn new tool paths, equipment, or processes to pass that knowledge on. The Cimquest manufacturing lab has CNC machines and access to the latest in 3D printing to enable us to show and prove the synergy between these technologies. It is a hub for teaching industry, college, and trade schools students, the next level of advanced manufacturing. This lab will fuse subtractive and additive manufacturing together for a production process that [...]

How Lumenium Saves 85% of Cost with 3D Printing

Lumenium is another of the pioneer customers. The company is a Virginia-based advanced engine technology company. They are also the inventor and developer of a highly innovative family of internal combustion engines (IDAR Engines). The Lumenium Inverse Displacement Asymmetrical Rotational Engine (IDAR Engine) is a novel design for producing robust, efficient, internal combustion. Its unique engine geometry provides unparalleled power density for dramatic efficiency gains and work output from a smaller, lighter engine. Qualities include lower fuel consumption and meaningfully lower emissions through more complete combustion at lower temperatures. Lumenium demonstrates how the connecting rod was scanned. Working with Desktop Metal, an optimized design with self-supporting angles to reduce 3D printing time and material consumption was created. This redesigned part improved the ratio of part volume to material volume with uniform geometry and no overhanging features, meaning that the support structures are extremely light in comparison to the weight of the part. Desktop Metal explains, “On the top and bottom of the saddle carrier, Lumenium typically machines the channels that mate onto the swing arms (also a Studio fabricated part). The Studio System delivers the ability to adjust density in certain sections of the part. We were able to increase the [...]

Desktop Metal Ships Their Metal 3D Printer to Google

The Desktop Metal Studio System with metal 3D printer, debinding station and furnace. The first metal 3D printing system from Desktop Metal is FFF/FDM based and also includes a debinder and sintering furnace. According to the company it is 10 times less expensive than existing technology today. The Studio System was first announced in April and uses a filament containing bound metal rods that are 3D printed to create a green part. This can then be sintered in the furnace to create a dense metal component. Early reports from pioneer customers praise the process. Metal 3D Printing at Google The first customer to receive one of the Studio System metal 3D printers was Google’s Advanced Technology and Products (ATAP) group. While Desktop Metal cannot reveal precisely how ATAP are using the machine, past projects at ATAP have tended to focus on mobile hardware. One such endeavour was the now defunct Project Ara – aimed at making a modular phone. “This marks the first time our team will be able to use metal 3D printing for rapid prototyping of our hardware parts,” said David Beardsley, manager of Google’s ATAP. “For prototyping, we have previously relied upon casting or using plastic 3D printing. [...]