Desktop Metal Named “2017 Best of What’s New” in Engineering

Popular Science Names Desktop Metal Production System "2017 Best of What's New" in Engineering Highlighting its speed and inkjet technology, Popular Science recognized the Desktop Metal Production System™ with its “2017 Best of What’s New” award in the Engineering category. The Production System is the first metal 3D printing system for mass production of complex metal parts that is up to 100 times faster than current laser systems. Arriving in 2018, the Production System delivers the speed, quality, and cost-per-part needed to compete with traditional manufacturing processes. Created by the inventors of ground-breaking technologies in both 3D and 2D printing – binder jetting by Ely Sachs and single pass inkjet by Paul Hoisington – the Production System builds metal parts in a matter of minutes instead of hours. Leveraging low-cost Metal Injection Molding (MIM) powder, it is designed to deliver high throughput and per-part costs that are competitive with traditional manufacturing processes—up to 20x lower than today’s laser-based additive manufacturing systems. "The Best of What's New awards honor the innovations that shape the future," says Joe Brown, Editor in Chief, Popular Science. "From life-saving technology to incredible space engineering to gadgets that are just breathtakingly cool, this is the best of what's new." [...]

Formlabs Announces Two New Materials

Formlabs’ library of versatile, reliable Engineering Resins is formulated to help product designers and manufacturers reduce costs, iterate faster, and bring better experiences to market. They recently announced the addition of two new materials for the Form 2: Grey Pro Resin for Versatile Prototyping and Rigid Resin. Grey Pro Resin offers high precision, moderate elongation, and low creep. This material is great for concept modeling and functional prototyping, especially for parts that will be handled repeatedly. This material is best for form and fit testing; prototyping injection molded products; mold masters for plastics, silicones, and more; jigs and fixtures for manufacturing. Rigid Resin is filled with glass to offer very high stiffness and a polished finish. This material is highly resistant to deformation over time and is great for printing thin walls and features. Rigid Resin has the highest modulus of all Formlabs materials. It has great impact strength, heat resistance, and stability, but is more brittle than Tough and Durable. This material is best for turbines and fan blades; jigs, fixtures, and tooling; manifolds; electrical casings and automotive housings. Please click below for more information on all of the Formlabs materials. More Info

3D Printing HP Labs Innovation

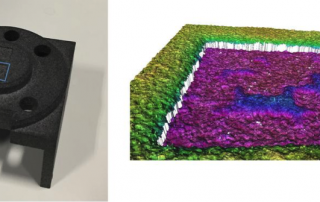

Progress in 3D authentication and identification brings 3D manufacturing closer Multi-jet-fusion printed part on the left and a high-resolution scan of the indicated portion of it on the right showing the micro surface structure used for authentication. An HP Labs investigation into accurately identifying and authenticating 3D-printed objects is helping enable a future where parts for high performance machines like jet engines are routinely printed to order. It may also aid the development of new systems for tracking physical objects of any kind on a massive scale. “To use a 3D printed part in a machine like an aero-engine, you need to be able to confidently identify and track that part after it has been printed from a known and trusted printer,” observes Bristol, UK-based researcher Stephen Pollard. One way to do that would be to add a unique identifier like a bar code to each printed item. But Pollard and his colleagues in HP’s Print Adjacencies and 3D Lab wanted to come up with an approach that added no processing or materials cost to the 3D printing process and that would also have applicability for 3D objects created via more conventional methods. Their solution: a low cost, three-stage, automated identification [...]

Jabil Sees the Future of Manufacturing with HP 3D Printing

This case study covers the world's third largest contract manufacturer and their use of HP Multi Jet Fusion technology. Jabil, a contractor that works with major consumer brands, faces the challenge of bringing more customization and complexity to the designs of their customers. Through HP’s solution they’re able to produce end-use parts in large volumes, and at a price point that’s competitive with traditional manufacturing. To download and read the full story, please click the button below. Download the Jabil Case Study PDF Please enter your Email address and Zip to Download the Jaebel Case Study PDF.

Part Inspection in Batches

You can easily perform part inspections in batches and automatically generate inspection reports for each part using a Creaform HandyScan scanner, along with Geomagic Control X software. The first step is to capture your parts’ geometry with a metrology grade, certified scanner. Scan each part in the batch, and export an STL file. It’s handy to put all of the scans in one folder. The next step involves creating a master file that will be used for comparison and inspection. Once you’ve imported the CAD file into Control X, add the appropriate dimensions, tolerances, Datums, and GD&T information to the CAD model. This critical inspection information may also be seamlessly transferred from CAD into Control X. Next, choose the method of alignment for your scan, so that you can align it with the CAD model correctly. Although we typically use the datums called out on the manufacturing drawing, various alignment methods are available depending on the need. Once you have the scan aligned, create the types of analysis that will be performed and orient their corresponding views. Last, you can prepare your report by choosing which information you want to include. You will notice that with little effort, the analysis results along with [...]

The New Rize One 3D Printer

There is a fairly new machine on the 3D printing scene, the Rize™ One. Capable of producing parts in a medical grade material, the Rize One sets out to eliminate the common hassles and headaches attributed to post-processing. If you've ever worked with common extrusion-based 3D printers, then you know that a part is typically not finished when it first comes off of the machine. With these systems, support material must be removed after the model comes off the build plate. Many supports can be broken away manually, but sometimes there is usually some resistance in areas that have strong adhesion. Dissolving support can be an option but may involve hazardous materials with special consideration needed for disposal. Regardless of the method, valuable time is added to the process. The Rize One addresses these post-processing obstacles through a patented Process called Augmented Polymer Deposition. APD involves the simultaneous extrusion of thermoplastic and jetting of functional inks. Release ink is jetted between support and model layers to allow for seamless support removal, while a marking ink can be used to print custom text or detailed images on parts. This is great for labeling part iterations, marking fixtures with instructions, or visual imagery. The Rize [...]