Desktop Metal Shop System Breakthrough Performance

The world’s first metal binder jetting system designed for machine shops, the Desktop Metal Shop System is capable of printing complex metal parts with the benefits that standards machine shops expect: unparalleled productivity with superior print quality while maintaining high levels of accessibility throughout the entire process. In addition to unlocking process and product innovations, the binder jetting technology at the heart of the Shop System is capable of delivering reliable high performance that meets the demands of a modern machine shop. With the ability to produce high-quality, fully-dense, near-net shape parts right out of the furnace, the Shop System’s high throughput and flexibility make it an excellent manufacturing choice for low-, medium-, and high-volume end-use applications. Unparalleled productivity The Shop System’s innovative single-pass print engine allows for rapid production of metal parts. Because the print bar spans the entire width of the print bed, entire layers of multiple parts can be printed in just a few seconds. That printing speed - up to 10x faster than laser powder bed fusion systems - allows the Shop System to print an entire build volume in a single 6 to 12-hour shift, depending on the height of the build. Build times are flexible and determined [...]

Choosing the Right 3D Printing Carbon Fiber Composite

Composites are a category of materials that encompass a large number of different properties and use cases. And even within carbon fiber composites, you can get vastly different results depending on the specific material you choose. In this article, we will take a look at the different UltiMaker carbon fiber composites available and help you decide which one is best for your needs. First, let’s look at which characteristics all the UltiMaker carbon fiber materials share. The pros and cons of 3D printing with carbon fiber Carbon fiber has long been a popular material due to its high strength-to-weight ratio. As a result, it is often used in high-performance (and high-cost) applications such as aerospace, automotive, and sports equipment. However, pure carbon fiber is a difficult material to work with and therefore expensive. Enter carbon fiber-reinforced composites. Made by adding chopped-up carbon fibers to a polymer, you can maintain many of the benefits of carbon fiber, while also inheriting the beneficial properties of the material it is combined with. This process works similarly to combining two metals to make an alloy. Carbon fiber composites as a category are useful for many reasons but the most notable is that it makes it possible to [...]

3D Printing Produces Face Masks for Treating Severely Burned Children

There are few things more tragic in life than children suffering severe trauma — but when an accident does happen, Romans Ferrari is one of the best places for recovery. Located close to Lyon in France, Romans Ferrari is a pediatric rehabilitation center that provides care to children and adolescents who have had trauma, brain damage, brain tumors, polytrauma, and severe burns. The center has immense experience providing treatment for severe facial burns, which includes specialized compressive masks that reduce the risk of complications and scarring. However, the traditional way to produce these masks involved an uncomfortable workflow that could induce post-traumatic stress disorder in children. Read on to learn how Romans Ferrari developed a new digital workflow for creating custom compressive masks for treating facial burns using 3D scanning and 3D printing, thanks to a multi-team collaboration among doctors, prosthetists, and engineers. How Severe Burns Are Treated Romans Ferrari accepts children and adolescents from across France who get referred to them by various hospitals after the initial (life-saving, ICU) treatments. The first step is to welcome the patient as soon as possible from a medical standpoint to avoid scarring complications from forming, such as scar contractures and hypertrophic scars, which mean volume [...]

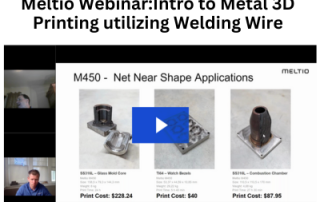

Meltio Webinar:Intro to Metal 3D Printing utilizing Welding Wire

Meltio Webinar:Intro to Metal 3D Printing utilizing Welding Wire Replayed from a live webinar held on August 8, 2023 During this webinar, our team of experts will guide you through the groundbreaking features and benefits of Meltio's advanced manufacturing solutions in 3D Printing. Whether you're a small business or a global enterprise, our comprehensive range of products is designed to meet the diverse needs of modern manufacturers.

Discounted Demo 3D Printers For Sale

Cimquest is selling several of our 3D printers that we use for demonstrations so we can make room for newer equipment. Each of these printers is extremely well maintained and is priced with everything required to get started; including, installation, materials, service consumables, and are backed with a full year of maintenance support (Same as New)! Xact Metal XM200CE An affordable metal powder-bed fusion 3D printer with an open materials platform. Create low cost metal 3D printed parts with 99.5% density (minimum) and +/- 0.2% dimensional tolerance as printed. With materials like 316, 17-4, Inconel & more; often same day with no need for post sintering. Priced new this unit goes for $137,076. Cimquest price is $97,016. That’s a 29% savings of $40,060! HP Jet Fusion 580 An incredibly fast (1800 cm3/hr) and highly versatile full-color 3D printer that integrates material mixing, loading, printing, and reclaiming material in one device. Produce high-strength, multi-color parts with fused PA12 Nylon powder at 80-micron layers. These solid & isotropic parts can be utilized in a variety of applications where other 3D printing processes would be impractical. Priced new this unit goes for $121,980. Cimquest price is $46,860. That’s a 62% savings of $75,130! Nexa3D QLS230 Most [...]

Metrology Minute – Creating and restoring a Custom View

During your inspection process, you might find an area that you would like to blow up and highlight. In the water pump example below, we wanted to create a cutaway and zoom in on the section of the circled hole region in Control X. In order to do this in Design X, you first need to add the dimensions. From there, you can turn on the View Clipping option, which is located in the Display tab down the right side of the viewing screen. After selecting Set, position the Clipping Plane Control to chop off all of the unwanted portions of the model, isolating just the portion you would like to display in your Custom Viewport. Next, select Add Viewport and a new view is created under the Custom Views section. Give the view a logical name, such as “zoom-in-holes”. This now becomes a settable viewport, selectable for placement in an inspection report or for retrieval while working on the inspection process. Please contact Joel Pollet with any questions. Contact Joel