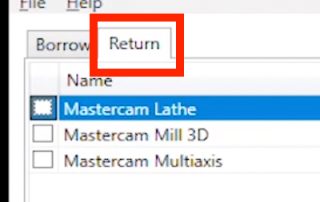

Mastercam Network License Borrow Utility

This post will show you how to use the Mastercam Network License Borrowing utility when using a networkable software license for Mastercam. In previous versions of Mastercam’s Licensing, there were 2 options: a single-user USB HASP key and a NetHASP USB key which gave access to multiple users. Now, Mastercam has moved to using software licensing keys. These licenses support Mastercam’s 2019 to present versions and support similar licensing styles. They include local, individual-use software licenses and also networkable software license pools. With the introduction of software licensing, it is now possible to borrow a license from the pool of licenses hosted on a network software license. The borrowed licenses will be checked out and stored on a local computer for offline or remote use. To use this option you must first be sure that Mastercam is closed on the system you wish to borrow a license for. Then you can launch the License Borrow Utility from the Start menu. This is located in the Mastercam Licensing Utilities folder. Now, just launch the License Borrow Utility and you will see the licenses that are available for borrowing. Before selecting the license that you want to borrow, first, select File and then open Options. [...]

How To Color 3D-Printed Resin and SLS Parts

This blog post will show you how to color 3D-printed parts using very simple dye. You can dye most SLS and SLA printed parts with off-the-shelf dyes to create a wide spectrum of colors and finishes. When it comes to engineering-grade 3D printers, you are often limited in choosing a color for the final product. Since most engineering materials focus on mechanical properties over aesthetics, you are often left with a white or gray part. By using an all-purpose dye, such as a Rit brand dye, you can dye your parts with just about whatever color you can think of. All you need is a container for the dye and some hot water. Start by gathering all of your materials and get the part you would like to dye. In our example, we used a durable resin part from a Formlabs 3D printer. Next, you will need to find a container that can hold the dye. You may use a small pot or a plastic container. After acquiring your container, you will need to heat up some water. A sous vide tool can work great in a pinch, but we used a support removal tank for large batches of dyed parts. Now it’s [...]

Which Metal 3D Printing Technology is Best for You?

Bound Metal Deposition™ (BMD) vs. Binder Jetting Metal 3D printing can be transformational, unlocking new design freedoms for part innovations and allowing for tooling-free production of spare parts or new product iterations. From office-friendly 3D printing without loose powder on the Studio System to the fast speeds of the world’s best-selling metal binder jetting machine, the Shop System, Desktop Metal has the technologies that offer the perfect fit to get started with metal 3D printing and the expertise to help you scale up to production. Learn more about two easy-to-adopt types of metal 3D printing from Desktop Metal. What is Bound Metal? Bound Metal Deposition™ (BMD) is an extrusion-based 3D printing process where metal powder held together by wax and polymer binder in pre-bound rods is heated and extruded onto a build plate, shaping a part layer-by-layer in an office-friendly process. Once printed, the part is sintered causing the metal particles to densify. What is Binder Jetting? Binder jetting uses an industrial printhead to selectively deposit liquid binder onto thin layers of powder particles before densification in a sintering furnace. Its speed, accuracy, and cost-effectiveness, particularly when compared to many laser-based technologies, make it a good choice for scaling additive to production. Click [...]

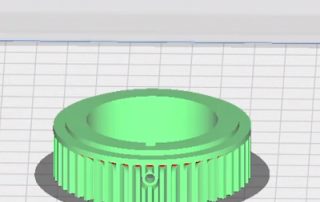

Metal 3D Printing with UltiMaker

Today’s blog post will show you how easy it is to produce high-quality metal 3D prints on your desktop FDM printer. We’ll be looking at a revolutionary metal filament from BASF, which comes in both 316L and 17-4 stainless steel in 1.75mm and 2.85mm filament widths. We will discuss some design considerations for printing with metal and the process of turning your green parts into fully sintered metal prints. Cura is a free FDM slicing software that is compatible with a wide range of FDM 3D printers. In our example, we used an Ultimaker S5 with a 0.6mm ruby Olsen nozzle. Steel filaments are naturally abrasive, so while you can use the brass nozzle that comes standard with your printer, it’s best to use a hardened steel or ruby-tipped nozzle. Some basic parameters that you should consider For the best part strength, consider printing your parts with 100% infill. If your parts need to be lightweight, consider using 50% infill with a grid or gyroid pattern. The most important factor for print success is the part geometry. When designing your parts for metal 3D printing, keep simplicity in mind. Try to keep overhangs below 45 degrees to minimize the need for support. Avoid [...]

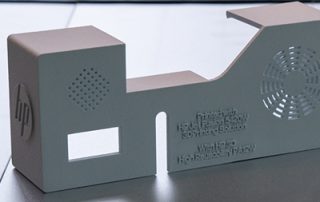

New HP Jet Fusion 5420 Capable of Printing White Parts

HP has unveiled its new polymer Multi Jet Fusion (MJF) 5420 system. This machine is capable of 3D printing high-quality white parts for customers in the automotive, consumer, healthcare, and industrial markets. It features a 380 x 284 x 380 mm build volume and a 3380.84 cm3 per hour print speed, the system is designed to allow users to manufacture with industrial-grade reliability, a low cost per print, and enhanced part performance predictability. According to HP, the technology has already allowed beta users such as DI Labs, Prototal Industries and Weerg to address “innovative white applications.” In fact, Jan Löfving, CEO of Prototal, says it has seen “immediate interest in the new white applications made possible by the latest addition to HP’s Multi Jet Fusion family,” and this makes it proud to be a HP Digital Manufacturing Partner. More Details

Formlabs Upgrade & Automate Printer Farm

Upgrade & automate your printer farm with the new Automation Ecosystem. Our friends at Formlabs are introducing their new Automation Ecosystem to further advance desktop 3D Printing and help bring new ideas to life faster than ever with the Form Auto, the Fleet Control, and the High Volume Resin System. The Automation Ecosystem achieves 24/7 part production without operator intervention, enabling high throughput 3D Printing at scale. Reach new levels of productivity and lower cost per part without increasing the complexity of running a fleet of 3D printers. With Formlabs Automation Ecosystem, production doesn’t have to ever stop. Form Auto: Instantly automate any new or existing Form 3/B/+ 3D printer with a hardware extension that will automatically remove finished parts and start the next print for back-to-back production. Fleet Control: Simplify multi-printer management with a suite of new, advanced features in Dashboard including centralized queue management and automatic printer assignment. High Volume Resin System: Continuously print on a Formlabs SLA printer for five times longer with the seamless delivery of 5L of resin through a pumping system. Also, upgrade if you own a Form 3 with these discounts. Learn More