Introducing the New MakerBot SKETCH Large

Welcome to the next step in the classroom 3D printing journey. MakerBot's SKETCH Large 3D printer offering comes equipped with printer training, student curriculum, and enough printing material for a whole semester included, all for $2399. To celebrate the launch of the SKETCH Large we’ll be giving you the MakerBot Educators Guidebook for FREE, PLUS 30% off on all SKETCH Large accessories when you purchase the SKETCH Large printer — that means you can get extra savings on extra training, guidebooks, print material and more! *Shipping for SKETCH Large to start later this year. What you get with SKETCH Large: Large Printing Capabilities 670 cubic inches of printing space (print up to 10 student projects at a time!) Enough Printing for a Whole Semester 3 Spools of Easy to Print, PLA Filament 3D Printer Training & Design Thinking Courses 1 x Teacher Seat in Printer Training Course & Curriculum Creation Course 15 x Student Seats in Printer Training Course & Design Thinking Courses Classroom 3D Printing Management Free, Cloud-based, printer preparation software Printer Features & Accessories to Keep 3D Printing Easy and Worry-Free Flexible Build Plates Heated Build Stage Enclosed Print Chamber & Air Filter Onboard Camera Spatula & Snippers

Metrology Minute – Twist Analysis

Performing 2D Twist Angle Analysis in Control X In this edition of our Metrology Minute, we are going to discuss the 2D Twist Analysis tool in Control X. It analyzes the deviation of twist angle between section profiles of the Reference and Measured data. Let’s use the turbine scan, aligned to the nominal CAD model shown below as an example. You would start with a pre-aligned model of Measured to Reference data. If you want to perform a 2D Twist Analysis on the blades using a section taken roughly centered through all of them, you would pass a plane, normal to the centerline axis of the turbine, through the rough center of the blade surfaces. The cyan curve represents the section plane to be used. Looking down the centerline axis, you can see your “2D Compare-like” section, comparing the nominal CAD model to the scan. Turning off the solid model and mesh provides a clear picture of the 2D Twist Whisker Plot. By setting the specific tolerance, as well as the Min and Max Ranges, we can have Control X calculate the planar twist at this selected planar location for each of the blades in the turbine. By zooming in, you can get [...]

Takumi H10 Demo CNC Machine For Sale

It's been 5 years since we began our partnership with Hurco CNC and Alta Enterprises. We are extremely happy to continue that relationship by using and showing the great capabilities of their CNC Machines. We first received a Hurco VM 10Ui 5 -axis mill and a Takumi H10 VMC back in Sept of 2017. The VM 10Ui has made its way to a new home running production parts and we now have the Takumi H10 available for sale for a great demo unit price. We need to move this amazingly accurate and rigid-double column-mill out in order to get a new 5-axis Hurco in its place. Some specifications of the H10 are shown below. If you are interested in this machine please contact Ray Dominguez at rayd@altamachinetools.com or call 484-695-9435. The Takumi H10 CNC machine is a world-class machine built for die/mold, aerospace, and high-speed applications. Machine Specs: Control Info- FANUC© 31i-MB Series Control Fanuc 31i control has 100 tool offsets and work offsets G53-G59 Travels- 40.16 x 27.56 x 19.69 in (1,020 x 700 x 500mm). Glass scales on all axis Table Size- 41.3 x 27.6 in / 1,050 x 700 mm Table Max. Load- 1,760 lbs / 800 kg Spindle Speed- [...]

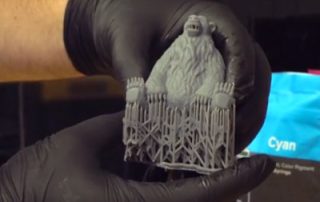

PreForm — Orienting Supports for Resin Prints

This blog post will show you the best way to orient and support your resin prints for the Formlabs 3 and 3L SLA printers. By modifying the support touch point size and density, you can have resin parts that simply break off of the support which reduces your post-processing time. When it comes to supporting models for SLA 3D printing, the goal is to have the least amount of support while still securing the model to the build plate. If your support size is too large, small puck marks can be visible on the model as the supports’ tips pull off some of the uncured resin. If you make the support size too small and the supports too sparse, the model will break away from the build plate, and the print will fail. PreForm is the standard slicing software for Formlabs printers. This software allows you to generate supports for your models. Some of the parameters that you can change are the touchpoint size, density, and support location. In this example, we have a simple box that can be supported using large touchpoints. We used 0.5mm supports with a density of 80%. Using the Edit Support feature, you can add extra supports in [...]

3D Printing and Veterinary Medicine

3D Printed Prosthetics To Save A Bird’s Life While caretakers at ZooTampa were performing a routine check-up on a 25-year-old great hornbill, they found a lesion at the base of the bird’s casque, the yellow helmet-like growth on top of the head. Further examination determined that the bird, named Crescent, was suffering from life-threatening cancer. The great hornbill is one of the most endangered bird species on the planet, driven out of its habitat by forest-clearing and hunted for its casque. Found only in the Indian subcontinent and Southeast Asia, ZooTampa’s hornbill is one of its prized attractions. The cancer, located near the bird's skull, couldn't be removed because it housed part of the bird's sinuses. The team wanted to know if they could remove the casque, and replace it with a 3D-printed replica designed specifically for this bird. Patient-specific prosthetics and devices have been used before in human procedures, but never for a great hornbill. Would it be possible, and if so, which materials would be safe for the bird? "Clinical literature has shown improved outcomes when patient-specific prosthetics, medical devices, and surgical guides have been used with human patients," Gaurav Manchanda, director of medical market development for Formlabs, said in a [...]

Bring SLS 3D Printing In-House

Outsourcing vs. In-House: When Does it Make Sense to Bring SLS 3D Printing In-House? Do you ever wonder about the value proposition of bringing selective laser sintering (SLS) 3D printers in-house and how it compares with outsourcing SLS parts from a service bureau? Or have you ever wondered about what it would be like to post-process these parts? In "Outsourcing vs. In-House: When Does it Make Sense to Bring SLS 3D Printing In-House?" a white paper created by Formlabs, they examine the value proposition of bringing SLS 3D printers in-house while providing an overview of the SLS 3D printing market today and discussing the six case studies they conducted. These six case studies represent three applications, and with them, they demonstrate the positive ROI of bringing SLS in-house for all different types of businesses. Additionally, you may learn about different post-processing techniques from a webinar we shared earlier this year. Cimquest's Tyler and Camil teamed up with Mark from 3D Cincy to discuss many different ways parts from an SLS printer can be post-processed. This webinar delves into 10 different methods, with examples, of providing parts with different finish outcomes. Watch Here Fill out the form below to download the [...]