The Verisurf ANALYSIS module

Perhaps one of the most compelling aspects of Verisurf software is that it runs “inside” of the Mastercam user interface. This offers a very comfortable "look and feel" to program not only your CNC machines but also inspection devices such as CMM’s, portable arms, and laser trackers. The Verisurf ANALYSIS module can import a nominal CAD model. Perhaps it was the exact model used to develop CNC toolpaths in Mastercam. The scan of the manufactured part may then be imported. …and automatically aligned to the nominal CAD model. Then, when the Analyze function is executed, all of the data points both within and outside of the pre-defined tolerance range are shown. All points may be shown… …Or just those out of tolerance. Color Maps may be produced. And the data can be quickly and easily exported to nicely formatted reports. Please contact Joel Pollet with any questions via the button below. Contact Joel

When Business Risks Pay Off – A Guide to Insanity

Spoiler alert! Cimquest has achieved great recognition in the industry as a result of a risky business transformation started 4-½ years ago as well as my talented team who at times believed in this transformation sometimes more than I even did. The achievements are: Cimquest was the #1 global partner for Desktop Metal Cimquest was the #2 global partner for CNC Software (Mastercam) Cimquest was the #1 global partner for Xact Metal So I am both amazed and proud of what we accomplished over the past several years. I think the more interesting story is how did we get here? What needed to take place to reach this level of success in just the 4 years since we completely rebooted our 3D Printing business and restarted with zero 3D Printer customers and zero revenue. First off, when many of my peers learned that we were shedding a relationship with the only 3D Printer partner we had which comprised over 50% of our business to pivot to a model of best-in-class providers with a more diverse set of products they either thought I was crazy or I was making a smart move. In my own head, I probably questioned my own sanity but knew [...]

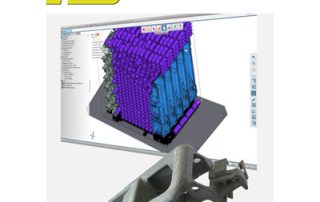

Cimquest Adds New Additive Manufacturing Product

We recently partnered with CoreTechnologie in order to add a new Additive Manufacturing product to our line-up. In the words of our CEO, Rob Hassold, "CoreTechnologie (a 24-year-old software development company) has amazed me with the speed of development and innovation of the 4D Additive software solution, a relatively new product in the industry. They have created a world-class product for Additive Manufacturing in just the past several years that rivals much more costly solutions. Cimquest's goal has always been to bring world-class affordable solutions to our customers, and we are excited to be partnering with such an innovative company as CoreTechnologie." CoreTechnologie provides CAX software solutions across wide-ranging industries. The company consistently optimizes its product portfolio and continues to secure technological leadership in the area of conversion software. Gamechanger for Additive Manufacturing The innovative 4D_Additive Manufacturing Software Suite sets new standards. Now for the first time 3D models from all common CAD formats can be read and prepared for additive manufacturing processes directly as an exact, intelligent and light B-Rep geometry. 4D_Additive reads CAD data from 24 different formats such as CATIA, NX, SOLIDWORKS, Creo, Inventor, STEP and JT as exact B-Rep geometry including all product manufacturing information (PMI), attributes, and design [...]

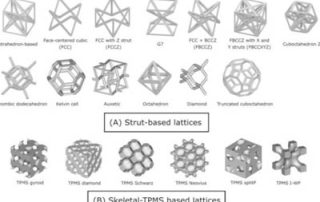

3D Printed Lattice Applications

A reprint from www.fabbaloo.com Lattice types [Source: Science Direct] A new research paper investigates the rather long list of applications for 3D printed lattices. Lattices are complex geometric structures that are sometimes referred to as “cellular”. This is because the geometry of the lattice is sometimes the space not occupied by “cells” inside of a volume. In traditional manufacturing, lattices are rarely used, except for foams. Foams are indeed a type of lattice, but the issue is that they are generally not controllable and tend to be uniform structure. With the advent of 3D printing technology, it became possible to literally control the lattice design, cell by cell. Sophisticated CAD software is now able to generate complex lattice forms, including, for example, lattice gradients, where the cells' size varies over a structure. Some industries have adopted 3D printed lattice structures as a strategic advantage. The most notable has been the footwear industry, where several players are involved in developing highly advanced midsoles. These midsoles are able to optimally transmit energy through ingenious lattice designs, making for shoes seemingly with superpowers. But what else can you use 3D printed lattices for? Some might be obvious, like lightweighting parts for aerospace, where every gram [...]

Desktop Metal Studio Sytem 2 Upgrade

Desktop Metal released a great lineup of 3D printers last year and we will recap some of those exciting new machines in weekly blog posts this month. Many of these new printers will also be showcased in our upcoming 3D Printing Online Seminar Series which will happen over the next couple of months. Please stay tuned for more details on that and in the meantime let's take a look at one of the new releases from Desktop Metal. Studio System™ Three new materials were released: 17-4PH stainless steel v.2, Ti-6Al-4V v.1, and D2 tool steel v.2! With the release of the Studio System™ 2 upgrade, you can skip the debind step and go straight from printing to sintering for the v.2 material system. To enable these new materials, we developed the High Purity Retort to improve the purity of the sintering environment as well as minimize the need for sintering getters. We didn’t just stop there. 2021 also saw the release of the PF1 Furnace, which contained many upgrades to not only increase reliability but also improve the ease of use and service. Together with updates to Fabricate® Cloud and Local, we’re excited to continue expanding the applications of the Studio System™. Keep [...]

PGV Cut Lead Times Using Desktop Metal 3D Printing

reprint from 3D Printing Industry PGV cut lead times by up to 80% using Desktop Metal 3D Printing technology PGV Industries, a Karnes City, Texas-based industrial equipment manufacturer, has begun integrating additive manufacturing technology into its day-to-day operations for the first time. Since recently installing one of Desktop Metal’s Shop System metal binder jet 3D printers, the firm has managed to remedy a number of issues it faced with traditional manufacturing techniques. As well as slashing manufacturing costs and lead times by as much as 80%, PGV has also reportedly benefitted from freed up internal production capacity and streamlined inventory management. Ramon Perales, President of PGV Oil Tools, said, “Energy itself is changing. As we’re moving forward, we want to make sure we aren’t reinvesting in legacy equipment, but in equipment that can take us to the future instead.” PGV’s Shop System 3D printer in the PGV Lab. Photo via Desktop Metal. The problem with traditional manufacturing Founded in 1983, PGV Industries has spent almost four decades manufacturing industrial parts for the oil and gas, aerospace, and medical sectors. Up until recently, the firm relied exclusively on conventional production techniques such as CNC machining. Some of the most immediate shortcomings of [...]