Desktop Metal Qualifies Titanium for Manufacturing with the Studio System 2

Desktop Metal Is the First Company to Commercialize Titanium for Bound Metal Production of High-Strength, Lightweight Components Reprint of Desktop Metal Press Release dated August 4, 2021 Desktop Metal recently announced it has qualified the use of titanium alloy Ti-6Al-4V (Ti64) for the Studio System 2™, an accessible metal 3D printing platform that offers customers the easiest way to print high-performance metal parts in low volumes for pre-production and end-use applications. With plans to begin shipping Ti64 next month, Desktop Metal will be the first and only company to make the material commercially available for extrusion-based bound metal additive manufacturing technologies. Ti64 is the most widely used titanium alloy and is characterized by its high tensile strength, corrosion resistance, and biocompatibility. With a high strength-to-weight ratio, Ti64 is considered an ideal material for high-performance production applications in industries such as aerospace and defense, automotive, and oil and gas. In addition, its biocompatibility makes it particularly desirable in medical applications, such as with surgical devices and implants. The Studio System 2 produces Ti64 with exceptional mechanical properties. Tensile properties include 730 MPa yield strength, 845 MPa ultimate tensile strength, and 17 percent elongation. These mechanical properties exceed those set by ASTM F2885-17 standards for [...]

Glaze Prosthetics Brings 3D Printed Prosthetic Production In-House with HP MJF 580

A reprint from 3Dpritintingindustry.com Investing in the MJF 580 will enable Glaze to produce and deliver customized prosthetics within two weeks. Photo via Glaze Prosthetics. Glaze Prosthetics, a Polish manufacturer of personalized prosthetic arms, has brought its entire 3D printing production process in-house with the addition of an HP Multi Jet Fusion (MJF) 580 Color 3D printer. Investing in the machine has enabled Glaze to digitize its production processes and work directly with clinicians to speed up previously lengthy workflows. The MJF 580 will also allow Glaze to produce and deliver customized prosthetics within a seven to 14 days turnaround. “Everyone wants to be part of the digital revolution, yet the prosthesis industry is one which is not traditionally born into digital,” said Franek Kosch, Co-founder of Glaze Prosthetics. “With the help of HP’s 3D technology, Glaze is democratizing digital workflows and giving everyone a chance to be a part of this new revolution.” Glaze Prosthetics was founded in Krakow, Poland, in 2017 after one of its founders 3D printed a customized prosthetic arm for a friend. Having identified a gap in the market for amputees wanting a light and durable prosthetic arm that could be customized, the company has since [...]

How Functional Color is Changing the Game in Additive Manufacturing

By Arianna Coger, a reprint from www.fabbaloo.com. “How Functional Color is Changing the Game in Additive Manufacturing,” was one a presentation given by HP Inc., at the recent Cimquest Xpand3D Design and Maufacturing Event that focused on the advancement of 3D printing methods to develop functional colored parts. The addition of color can help improve the clarity and accuracy of models as well as enable the easy production of parts that are ready for consumer usage. Common methods of adding color to prints often involve paint or filament changes, which are labor-intensive solutions, binder jetting, which cannot produce strong parts, or multiple extruders, which can have reduced precision. The HP Multi Jet Fusion printers can be used to print colored parts with fully fused nylon as the material, providing high durability. This method of printing lets companies produce functional prototypes due to the enhanced mechanical properties of nylon, which can be used to accurately model intricate and small details for parts without breakage. HP MJF color printing can be used for a variety of purposes, ranging from developing color-coded fixtures to anatomical models to customizable consumer goods. HP’s color 3D printing technology can help companies expand the capabilities of their prototyping, manufacturing, and [...]

New Nylon 11 3D Printing Material

Formlabs has released a new 3D printing material for the Fuse 1 platform - Nylon 11. For ductile, robust parts, Nylon 11 Powder is their higher performance, bio-based nylon material for functional prototyping and small batch production. Nylon 11 Powder is suitable for printing parts that need to bend or take impact. Why Choose Nylon 11 Powder? Nylon 11 Powder is a ductile, strong, flexible material for when durability and performance are key. High Ductility: Print end-use parts that can handle wear and tear over time. Thin Walls: Print enclosures, ducts, and other geometries with ease using Nylon 11 Powder. No Nitrogen Needed: 3D print in Nylon 11 in-house without a nitrogen supply resulting in less upfront costs and operating costs compared to most other SLS systems. Environmental Stability: Nylon 11 prints absorb very little moisture and are resistant to light, heat, and chemicals. Download the brochure for more details. Brochure Download

The Future of CAD

by Randall Rothbort. A reprint from www.fabbaloo.com written as a follow-up to our recent xpand3D event. The Future of CAD discussion was a great view into the future technologies being used and incorporated into CAD software. Jon Hirschtick (founder of SOLIDWORKS and Onshape), Blake Courter (CTO of nTopology) and Rob Hassold (CEO of Cimquest) spoke regarding current developments in CAD, future goals, and how the industry will be shaped by current technological advancements. Two main focuses of the discussion were the impact of AI/Machine Learning on CAD, as well as the implementation of cloud computing into the systems. All three universally saw the potential of AI in improving the capabilities of CAD systems, allowing more menial and rule-based parts to be created automatically. However, while Blake and Rob saw this as reducing the role of the designer, Jon saw this as just a progression of the tool, amplifying the engineering rather than reducing it. This connects to a later discussion on parametric design, especially regarding producing alternative parts based on one master part. Rob brought up specifically how machine learning will be adapted to create these parts, reducing the time spent by engineers designing repetitive components. This functionality is just beginning to be [...]

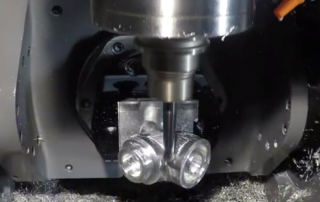

Mastercam Drill Operations for Tapping

This blog post will discuss creating Mastercam drill operations for tapping. The order of operations for the tapping cycle will typically share common parameters from part to part. By creating custom drill operations, you can increase the efficiency of programming for these common features. Our example fixture plate has multiple drilled and tapped one half 13 holes. Starting with the chamfer drill toolpath, we took advantage of the solid feature defining the tapped hole. Remember that you can use the ctrl key to select all the matching diameters. Reset the whole sorting as needed and with the hole location selected, you can associate the spot drill to the toolpath. In the Cut Parameters, the depth for the transfer can be set to zero due to the chamfer being defined in the solid feature. The Linking Parameters were all set to incremental. By backplotting the toolpath we saw the spot drill was feeding to the proper depth matching the chamfer. Next, we opened a drill toolpath for the tap drill operation. Just close the whole selection utility and select yes to keep the drill toolpath. Use the left mouse button to select and drag the geometry from the chamfer tool path and release it [...]