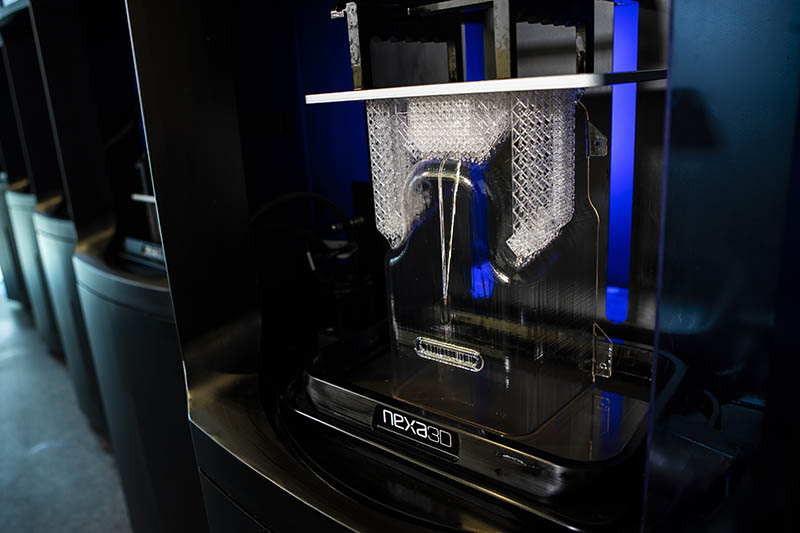

Nexa3D Expands Partnership with BASF Forward AM

Ultrafast Photoplastics for Rapid Prototyping Nexa3D, the maker of ultrafast stereolithography production 3D printers, recently announced that it has expanded its partnership with BASF Forward AM to deliver three new ultrafast photopolymer materials through its expanding Nexa3D channels globally. Nexa3D’s collaboration with BASF Forward AM leverages their combined capabilities to deliver faster additive-manufactured prototypes across multiple industries, leveraging the 20X productivity advantage of its ultrafast NXE 400 3D printer. No other manufacturing process offers as many possibilities for greater design agility, supply chain resiliency and rapid implementation at every phase of the product lifecycle. Combining Nexa3D’s productivity with Forward AM’s rapidly expanding suite of tailor-made photopolymer formulations makes it possible for customers to rapidly design a wider range of parts such as housings, enclosures, pipes, packaging products, and footwear components with greater performance and functionality. x45-NATURAL is a tough material that is ideal for models and functional prototypes requiring high strength and durability. Capable of much higher print speeds than current materials, x45-NATURAL features excellent out-of-printer properties with robust print styles to ensure high first-time build success. Supporting a wide variety of applications with short processing times, x45-NATURAL’s draft build mode enables companies greater flexibility within their manufacturing processes. To learn more about [...]

Latest 3D Printing Promos from Ultimaker & MakerBot

Get 50% off Ultimaker Material Bundle With a purchase of an Ultimaker 2+ Connect, Ultimaker S3, Ultimaker S5 or Ultimaker S5 Pro Bundle Method and Method Carbon Fiber Printers are 20% off—20% off Labs extruder Method X and Method X Carbon Fiber are 25% off—25% off a labs extruder And receive a FREE Labs spool with your purchase Promotion Expires June 30th SKETCH 5% off across your ENTIRE order + 3 Free Spools of PLA Any Color. Promotion Expires June 30th Contact Us Today

Metrology Minute May

The Benefit of using GD&T and a Positional Tolerance vs +/- Tolerances When creating a part like the one below, the intent of the four holes is likely to fasten this component to another in the final assembly where the round holes will accept round fasteners. We want to look for a way to maximize our tolerance to provide as few scrapped parts as possible. A typical dimensioning scheme using +/- tolerances might look something like this, defining the hole’s locations off of the adjacent flat surfaces. Furthermore, consider the datums as playing a key role in how the part will fit inside the final assembly. The datums allow the designer to simulate the part in the assembly. Consider datums A and B below. Now consider how the hole’s location tolerance is placed as +/-.050”. This created a tolerance box of .1” x .1”, surrounding the ‘perfect’ hole center. Therefore, any manufactured holes where the center points fit inside that square will represent an in-spec hole location. But now, consider any of the four corner points of the box, representing the extreme location that still fit the tolerance conditions. Our goal in manufacturing is to provide as much acceptable tolerance as possible to [...]

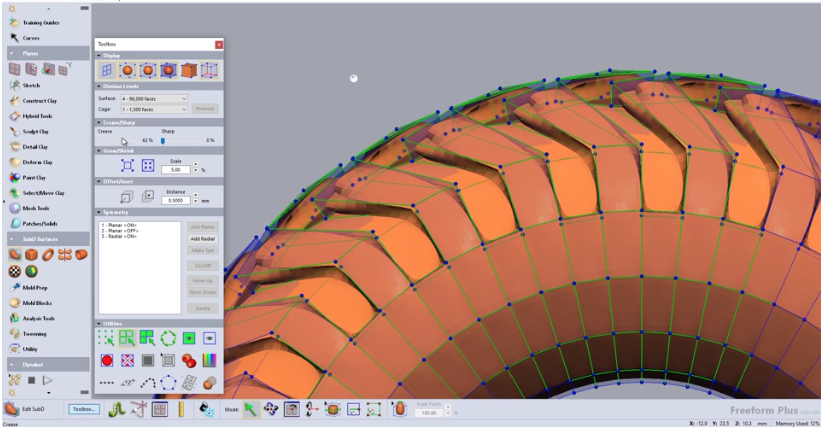

Modeling a Car Tire with Geomagic Freeform

In this post, we will walk through how to create a tire model with deep treads using Geomagic Freeform. We will do this by applying the basics of Sub D modeling to create a real-world part. Let’s start by creating a Taurus. Inside the editing tools, we can see that we have 61,440 faces on Level 5. We have two planes here - the XY and YZ plane. For the XY plane, we keep Symmetry on because anything we do on the front of the tire we want to cross over to the back. We can turn off YZ Symmetry but we also need to create Radial Symmetry. Radial Symmetry allows for any changes to the shape to be perpetuated all the way around the circumference of the tire. Using a haptic device, we select an edge and click Radial. From here we can take the Control Cage, and promote it to level 2 which quadruples the number of faces. This gives us the ability to create finer details on the tire. It also creates a centerline of edges to manipulate for modeling. The first thing we want to do is create a Zigzag pattern. We select two of these edges and then [...]

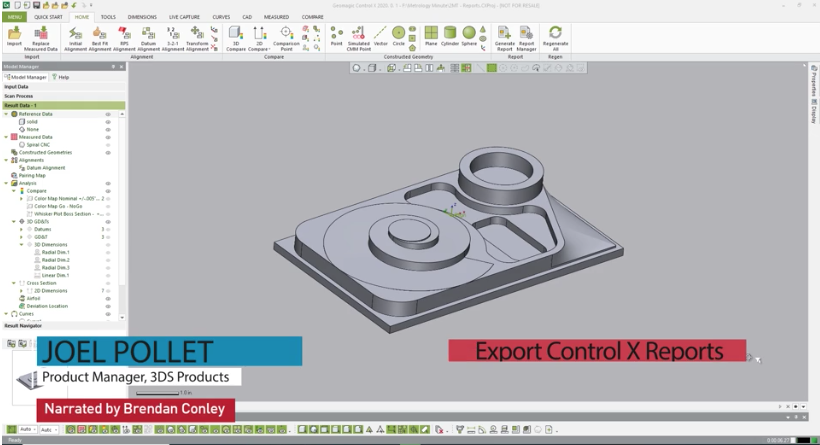

How to Export Data out of Control X

This blog post will explain how to export data out of Control X to be used for review or downstream applications. Control X Metrology software allows you to leverage rich data to understand why parts are in or out of tolerance. In working with a CAD model, known as the reference data, when you select the reference data node, a window appears in the bottom left that shows how the model will appear in the report. If you want to change the angle, you can rotate the part and simply click as shown below to update the orientation in the report. Now let’s move on to the Measure Data, which is the actual scan data. For Datums, there are three datums to fins, two flat faces of A and B, and datum C for the cylinder. Under Compare, there are multiple color maps including a standard one and then a Go-No Go color map, which simply shows what is inside tolerance and what is outside of tolerance. Below we have a whisker plot which is essentially a 2D color map. The black line is the exact geometry of the CAD model, and the colors are the cross-sections of the scan. Hovering over the [...]

Williams Racing Announces Partnership with Nexa3D

Williams Racing recently announced a new partnership with Nexa3D, bringing the fastest polymer 3D printing to the world of Formula One. Beginning this month, Nexa3D’s NXE400 ultrafast photoplastic 3D printer will be available to manufacture functional wind tunnel parts for aero testing purposes. The company’s NexaX software will enable high-performance additive manufacturing processes using modern computation architecture to develop light-weighted parts and accelerate the file-to-part process. With Nexa3D’s technology, Williams Racing will be able to quickly design and manufacture complex, light-weighted parts in minutes, compared to hours with traditional manufacturing, while minimizing material usage and waste. The NXE400 breaks printing speed barriers with its 20X productivity through its proprietary Lubricant Sublayer Photo-curing (LSPc) technology and patented structured light matrix capable of reaching top speeds of 1Z centimeter per minute. Al Peasland, Head of Technical and Innovation Partnerships at Williams Racing said, “We’re extremely excited to announce our partnership with Nexa3D and look forward to enhancing our additive manufacturing capabilities with their innovative high-speed printing technologies. Formula One is a challenging environment, that demands a continuous improvement philosophy in order to remain competitive. Our partnership will enable the team to continue to push boundaries in 3D printing, and present new opportunities for Nexa3D to [...]