HP and Ford Team Up to Convert 3D Waste Into Auto Parts

reprint from Digital Engineering Companies found way to extend life of already-used 3D printed powders and parts, turning them into auto components for Super Duty F-250 trucks, creating closed-loop on waste. Ford says 3D printing has potential to revolutionize customization of low-volume vehicle parts, accelerate sustainability. Image courtesy of HP and Ford. Ford is seeking to drive the future of automotive 3D printing, this time teaming up with HP to innovatively reuse spent 3D printed powders and parts, closing the loop and turning them into injection molded vehicle parts, the companies say. The resulting injection molded parts are better for the environment with no compromise in the durability and quality standards Ford and its customers demand, the company says. The recycled materials are being used to manufacture injection-molded fuel-line clips installed first on Super Duty F-250 trucks. The parts reportedly have better chemical and moisture resistance than conventional versions, are 7% lighter and cost 10% less. The Ford research team has identified 10 other fuel-line clips on existing vehicles that could benefit from this innovative use of material and are migrating it to future models. “Finding new ways to work with sustainable materials, reducing waste and leading the development of the [...]

Design for Additive Manufacturing: Internal Features and Channels

Additive manufacturing is rapidly rewriting the rules of how metal parts are made, and it’s doing it with the help of a new design language - Design for Additive Manufacturing (DfAM). Developed to take advantage of the enormous design freedom that comes with 3D printing, DfAM allows manufacturers to unlock a host of benefits - from highly complex geometry to the use of generative design tools to the ability to create internal features and channels - and create parts that would otherwise be too difficult or costly to justify with traditional manufacturing methods. Internal Features and Channels For some 3D printed parts, the greatest benefit isn’t on the outside, but the ability to create complex internal features. By building parts layer by layer, 3D printing opens new possibilities for engineers and designers to create parts with internal features - like conformal cooling channels - that would be impossible for conventional manufacturing approaches. Incorporating such features into parts can often result in improved performance like faster cooling rates for injection molds and improved heat transfer rates for heat exchangers, leading to production increases as well as reducing both the time and cost of creating parts. Part Examples Asthma Inhaler Mold Insert Asthma Inhaler [...]

3DGence Announces the INDUSTRY F350 3D Printer

3DGence announced a new industrial 3D printer for their INDUSTRY line, the F350. The 3DGence F350 production 3D printer Previously the company launched the F340 and F420. The new F350 seems to fit in-between the previous two models, as you might suspect. However, unlike most “mid models”, it isn’t just about a build volume that fits in-between. 3DGence has implemented an interesting combination of thermal capabilities as well. Each of the three INDUSTRY models uses the FFF process with 1.75mm filament. They all sport dual extrusion by means of swappable modules, which offer the ability to very quickly put in place hardware that’s optimized for specific materials. These modules can be interchangeably used on each of the machines. All machines in the INDUSTRY line include actively heated build chambers and hot ends that can hit a sizzling 500C. All machines include filament storage that’s also heated. With all those common characteristics, how do these machines differ, and how does the new F350 fit into the lineup? Let’s look at some specifics. The build volumes are the most prominent difference, but not the sole difference. The F340’s build volume is 260 × 300 × 340 mm; the F350’s build volume is a [...]

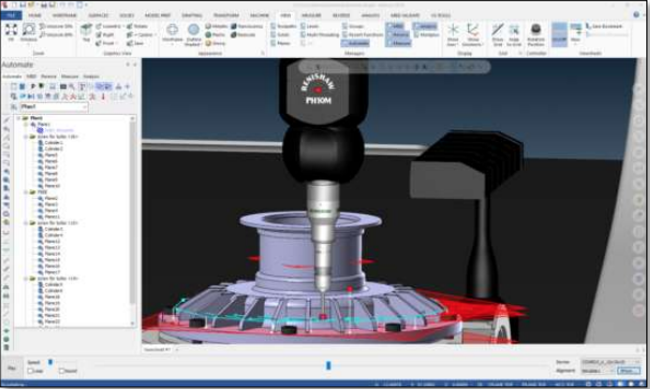

What is the Universal CMM?

The Universal CMM (Coordinate Measuring Machine) is a software-only alternative to many of the cryptic and clumsy programming software products that ship with CMM’s and Head controllers. The Verisurf AUTOMATE module provides communications between Verisurf software and the CMM giving you a simple user interface to address authoring inspection programs from a variety of supported CMM’s. Tolerating outdated metrology software is now a thing of the past, especially for companies owning multiple CMM’s, each with its own clumsy programming software. You can now switch your CMM programming to a common platform for both CNC programming and CMM inspecting. Powered by Mastercam Design, all Verisurf software runs ‘inside’ the Mastercam User Interface, providing a common, industry-leading programming interface from the most popular CAM system in the world. Tool changers for probe swap-out are fully supported through the UCMM. Even support of indexing heads, disk probes and star probes are fully supported and easy to address through this powerful CMM programming tool. The UCMM connects Verisurf software with some of the most powerful and popular CMM’s on the market today. Supported CMM’s include: Brown & Sharpe / DEA controllers Brown & Sharpe DCC CMM’s Leitz Controllers Leitz DMM CMM’s Mitutoyo Controllers Mitutoyo DCC CMM’s Wenzel [...]

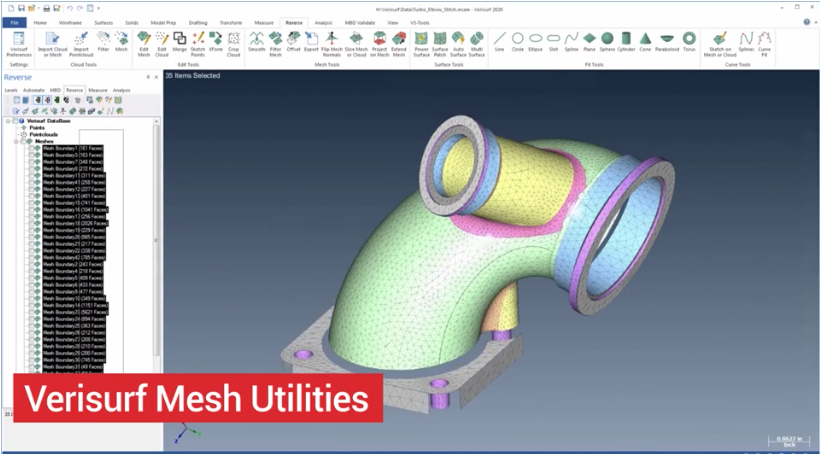

Verisurf Mesh Utilities for 3D Data Preparation

The powerful Verisurf Mesh utilities allow you to create high-quality meshes for 3D printing, machine from STL, and use as nominal models for inspection. Power Mesh simultaneously can create, merge, clean up, refine, smooth, hole fill, and extend the mesh. Advanced options control mesh density and can close mesh volume. Power Mesh can create water-tight mesh, a natural first step in any reverse engineering workflow. Stitch Mesh connects discontinuous meshes along their common boundaries while maintaining the original mesh definitions. It creates a single water-tight mesh from meshes that were imported from individual CAD surfaces. With Stitch, you can also reassemble portions of a larger mesh that were separated during editing and cleanup. The tolerance controls the allowable gap or overlap between adjacent meshes. This works without having to remesh or filter the constituent meshes. Quad Mesh creates triangles from the quadrilaterals that follow the flow of the mesh curvature. It’s used to improve mesh quality prior to surfacing and to align the mesh with the part edges. Settings enable control of density and smoothing and allow sharp creases to be maintained. Even random unstructured scans from a hard probe can be made uniform to improve surfacing. Optimize Mesh reduces the overall size [...]

HP Partners With Solize to 3D Print Spares On-Demand for Vintage Nisan GT-RS

Japanese manufacturer SOLIZE has worked with multinational printing firm HP to 3D print spare parts for heritage models from Nissan’s NISMO line of sports cars. Using 3D modeling and HP’s Multi Jet Fusion (MJF) platform, SOLIZE’s engineers have been able to design and 3D print discontinued parts for vehicles such as the Skyline GT-R on-demand. Working as part of Nissan’s Heritage Parts program, the firms effectively demonstrated how the carmaker could benefit from digitizing its inventory, by reducing its warehousing costs as well as its industrial waste output. “We are seeing leaders of industry like Nissan recognize the massive cost implications of storage, molds and logistics for replacement parts,” said Jon Wayne, Head of Global Commercial Business for 3D Printing and Digital Manufacturing at HP. “Digital manufacturing is a viable, long-term solution for accelerating production, transforming supply chains and activating industries such as automotive.” “TOGETHER WITH SOLIZE, WE ARE FOCUSED ON HELPING BUSINESSES TRANSFORM THEIR MANUFACTURING WITH SUSTAINABLE, DIGITAL PRODUCTION.” SOLIZE has used HP MJF 3D printing to create spare parts for Nissan’s legacy NISMO sports cars. Photo via Nissan NISMO. 3D Printing to Boost GT-Rs Set up in 2017, Nissan’s Heritage Parts program is designed to provide owners of legacy [...]