Metrology Minute – Airfoil Analysis using Control X

Analyzing airfoil shapes is easier than ever using the Control X Airfoil Analysis technology. Upon completion of scanning the airfoil and aligning with the nominal CAD model, the software is able to return dozens of useful parameters necessary for complete airfoil analysis. Some of the parameters include: Leading and trailing edge radii Leading and trailing edge positions in space Maximum chord height Leading (and trailing) Edge position in space relative to the model origin. Axial chord length Leading and trailing edge thicknesses, as well as maximum airfoil thickness across the widest section, maybe easily requested using this powerful tool making complete airfoil analysis simple with just a few clicks of the mouse. Additionally, analyzing airfoils often requires identifying points along a section’s periphery and comparing those to the corresponding points from the nominal CAD model. Deploying the Comparison Point function in Control X, this too is handled by just a click or two of the mouse. For any questions or comments, please contact Joel Pollet at jpollet@cimquest-inc.com.

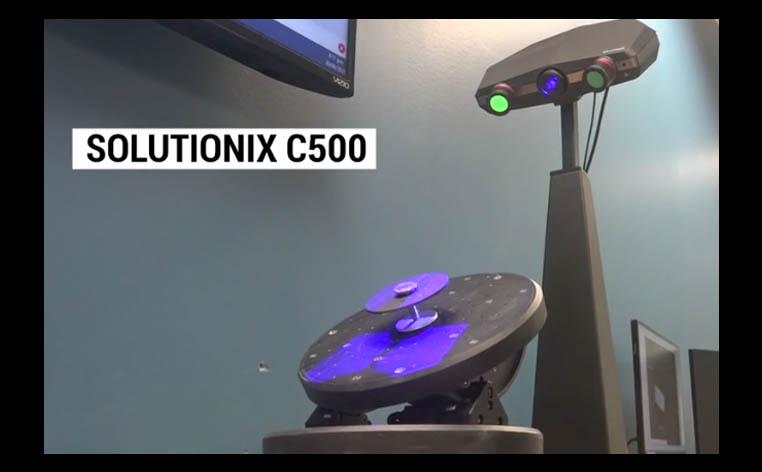

Solutionix 3D Scanner

Cimquest recently added a new 3D scanner to our portfolio. It’s called the Solutionix C500 and it is a structured Blue LED scanner. It’s designed to be user friendly so that both novices and experts can operate it with ease. It comes with the scanner, the stand, and an automated rotary 3-axis turntable. It combines well-written, intuitive software with simple, easy-to-learn calibration, scanning, and post-processing routines. Here are some of the key features . . . Often, a scanner’s field of view is a determining factor when choosing the scanner that is right for you. The C500 eliminates this limitation by providing you with four different lens sets from a field of view as small as 3.5” to one as large as over 19.5”. Switching between lens sets can be done in minutes, allowing you to accommodate a variety of part sizes all with the same scanner. The dual 5-megapixel cameras allow you to achieve accuracy capabilities that range from +/-.0015” for the largest lens all the way down to +/-.0005” for the smallest lens. These cameras also feature great resolution with the smallest lens having an incredible point spacing of .001” which can capture the fine detail of a coin, to the largest [...]

Nexa3D xCE-White – a New 3D Printing Material

Nexa3D Unveils xCE-White for 20X Faster Production of Parts and Injection Molding Tools Nexa3D, the maker of ultrafast polymer production 3D printers, recently announced the immediate availability of a new photoplastic material called xCE-White, a functional polymer for producing end-use plastic parts and injection molding tools in minutes. xCE-White is the fastest single cure material in the company’s portfolio to date, helping deliver 20X productivity increases in AM and boasting high flexural strength comparable only to dual cure cyanate esters. Developed for the company’s NXE400 3D printer, xCE-White can be used to produce isotropic parts that are well suited for a variety of automotive parts, automation and robotic assemblies, and many industrial components at speeds similar to injection molding processes. “We are very excited to bring to market our fastest functional photoplastic material yet, underscoring Nexa3D’s commitment to providing our customers with the highest levels of design agility and supply chain resiliency both now and post-Covid-19 that produce functional parts literally within minutes,” said Michele Marchesan, Chief Growth Officer for Nexa3D. “With xCE-White available through our rapidly expanding global reseller network, we are delivering a new performance photoplastic that is ideal for many production parts in addition to being an outstanding injection molding [...]

Seeking Applications Engineering Specialist

Cimquest is hiring and is looking for an Applications Engineering Specialist. Job description below. If you are interested in applying, please provide your resume and salary expectations to careers@cimquest-inc.com. OPPORTUNITY DESCRIPTION: This position is for an Application Engineering Specialist for our growing line of 3D Printer solutions including HP and Desktop Metal as well as several other technologies. The specialist will be based out of our 25,000 sq ft Branchburg, NJ headquarters. Approximately 30% travel will be required; however, most of that would be within a 4-hour drive radius of our NJ facility. Full training will be provided for the technician both internally and by our vendors. Provide application consulting with clients and Cimquest sales reps Help manage the usage of our own 3D Printers for printing demo and print service parts Manage certain product/vendor relationships from a technical aspect Provide 3D Printer installation and training services at customer sites Service 3D Printers Provide professional and customer service oriented telephone support for customers Help manage the usage of our own 3D Printers for printing demo and print service parts Provide demonstrations of the 3D Printers at our facility and trade shows Post-process parts as well as package and ship parts to customers COMPENSATION [...]

Geomagic Wrap for Point Cloud Editing

Let’s take a look at Geomagic Wrap, a powerful software for point cloud or mesh editing. Wrap has a collection of tools used for cleaning and finalizing polygonal files to make them suitable for part inspection, reverse engineering, 3D Printing, and more. The files can come from a traditional CAD system, a laser or structural light scanner, or even a CT scanner. While standard tools for patching of holes is very robust, other tools for making mesh files less dense (aka Decimation) or increasing a scan’s polygons (aka Refining a Mesh) offer excellent control over mesh file resolution. The Closed Manifold Tool checks to see if mesh files form full volumes and would therefore be 3D printable or could be made into a solid model. The quick smoothing of edges and rough spots on a part are quick to execute, using the enhanced Smoothing set of tools. The Defeature tool functions as a magic eraser. Anyone who has dealt with mesh files is familiar with trying to adjust certain areas of a part where the mesh didn’t necessarily come out smooth due to either dirt or grease on the part or simply a bad scan. Isolating and exporting of individual analytic part features [...]

How Innovative Plastics Is Using Desktop Metal 3D Printing

Using the Studio System by Desktop Metal, Innovative Plastics created mold cavities and cores in far less time - and at significantly less cost - than traditional methods. In addition, the company was able to incorporate features like internal channels into the molds, reducing molding cycle time and increasing their productivity. The most common manufacturing method for plastic parts, injection molding works by forcing melted plastic into a mold under pressure. Within seconds, the plastic cools, allowing the mold to open and eject the solidified part, and the cycle starts again. Today, the injection molding process is used to produce a huge variety of parts and products, everything from children’s toys to automotive parts to surgical tools. For companies, like Innovative Plastics, that specialize in the process, many of the challenges they face come down to one key issue - speed. With constant iteration in product design and the demand for tens of millions of plastic parts per year, injection molding companies must be able to create new molds and retool manufacturing lines quickly to minimize downtime. In addition to quickly creating molds for new products, molding companies also seek to shorten the cycle time - the time it takes to inject plastic, [...]