Is Metal 3D Printing Ready for Primetime?

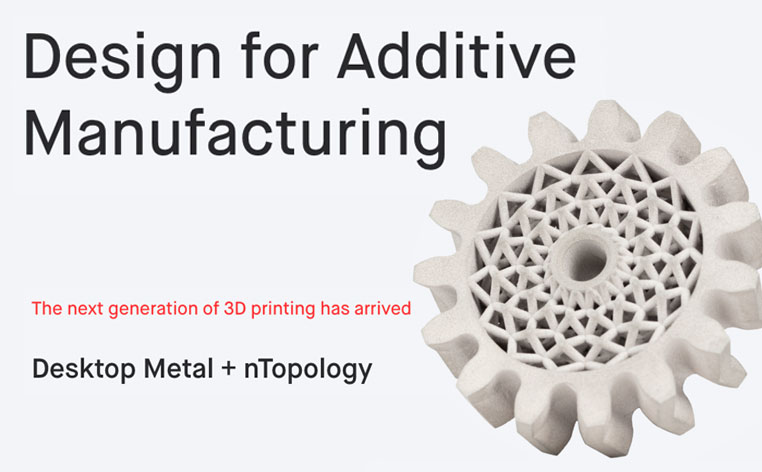

By Joseph Castine A reprint from https://www.fabbaloo.com/news/lessons-from-cimquests-2021-xpand3d-event-part-one With the rapid expansion of the additive manufacturing industry, metal printing technologies continue to emerge, but this raises the question “Is Metal Printing Ready for Primetime?” The discussion by Nate Higgins (President, FreeFORM Technology), Ric Fulop (Founder/CEO, Desktop Metal), Bob Hedrick (President, CAMufacturing Solutions), Kenneth Fortier (Product Owner – Visualization and Simulation, Mastercam), and Rob Hassold (CEO/Founder, Cimquest) came together to discuss. The metal segment is one of [...]