3D Scanning for Large Objects

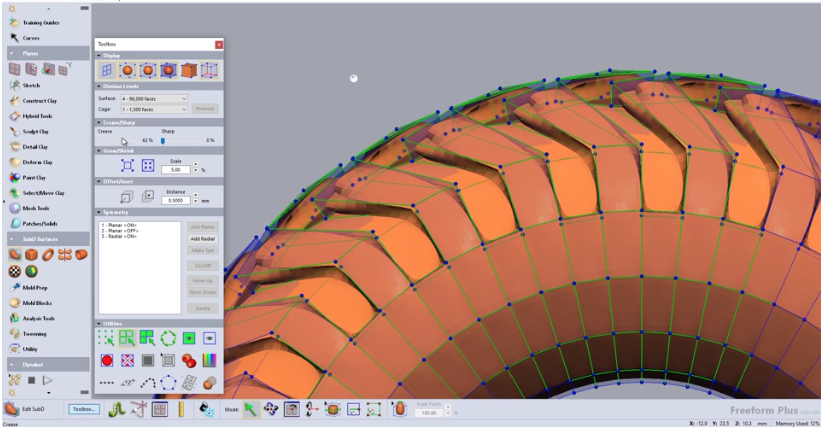

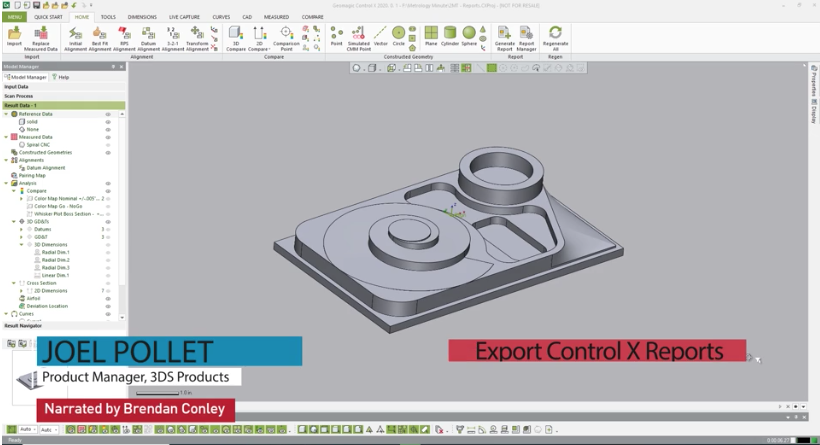

https://cimquesttv.wistia.com/medias/biiayb1itt?embedType=async&videoFoam=true&videoWidth=640 3D Scanning for Large Objects In this episode, we 3D scan a large bike frame with the Freescan Trak. It is suitable for large-scale inspection and reverse engineering in the aerospace, automotive, shipping, and energy industries.