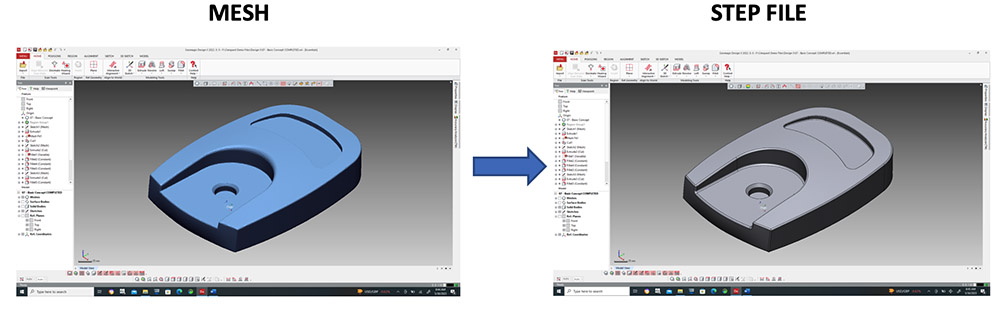

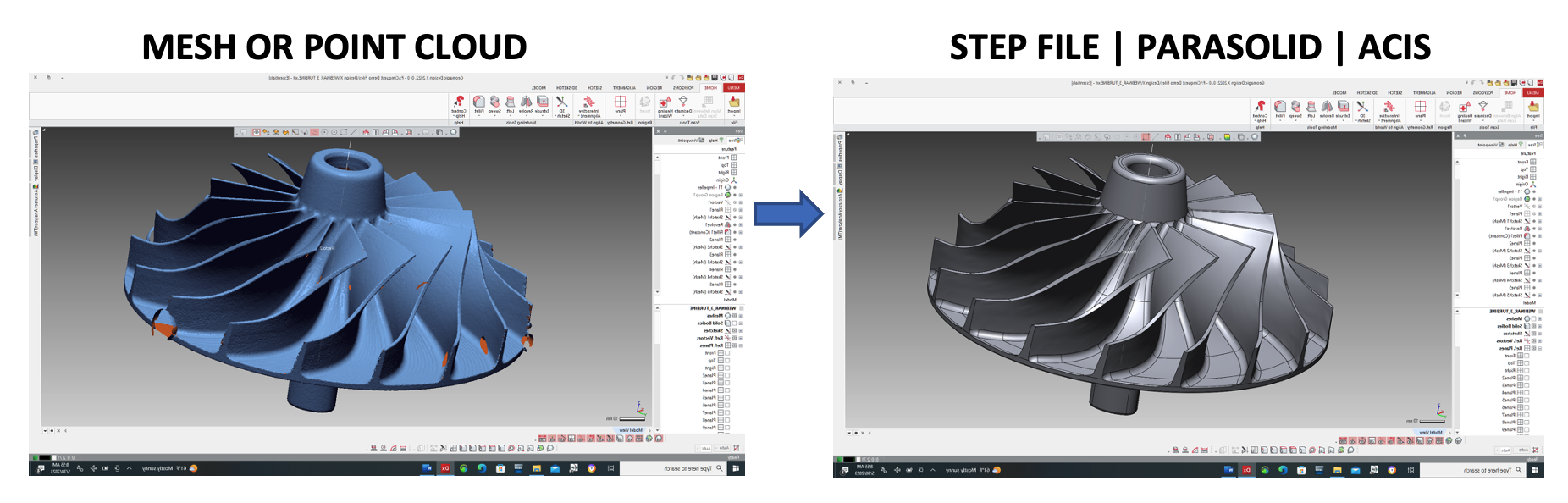

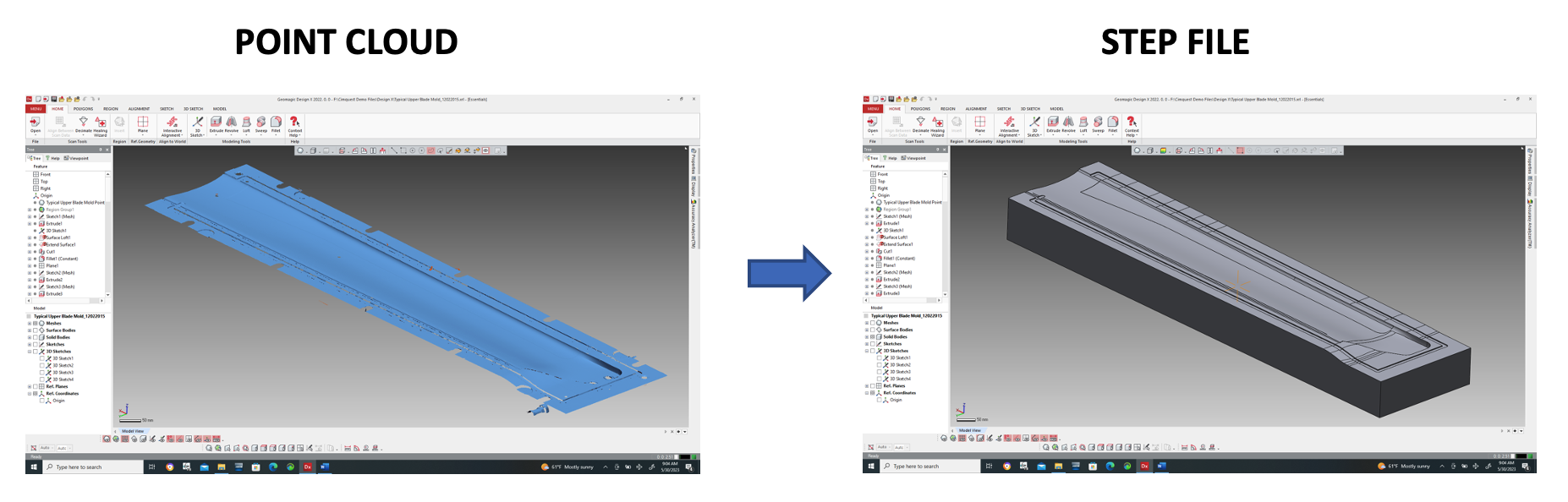

Geomagic Design X Essentials can take a scan or point cloud from a scanner and use it as a template for reverse engineering the shape into a completely machinable Neutral or Kernel file (Step, ACIS or Parasolid).

2D Pockets that require 2-axis machining that include G02/G03 circular tool motion, G81/G83 point-to-point applications, etc. are all fully achievable, using Design X Essentials to create the model.

The all-too-common Autosurface created by most reverse engineering software tools from mesh data is now a thing of the past. Autosurface algorithms generally create enormous, poor-performing models for machining that are somewhat unusable and not editable. They certainly cannot be used to machine analytic features that produce linear and circular motion for basic milling and turning operations.

Design X Essentials produces fully usable neutral and kernel files. Resultant models will appear as if they were built using a CAD system.

What about more complex machining?

In the world of 3D surface machining, Lofted and Swept surfaces and the like, including Guide Curves may be built and 3-axis simultaneous tool motion can be created. In fact, full 4 and 5-axis parts or parts to be machined using 4th or 5th-axis positioning may also be created using Design X Essentials.

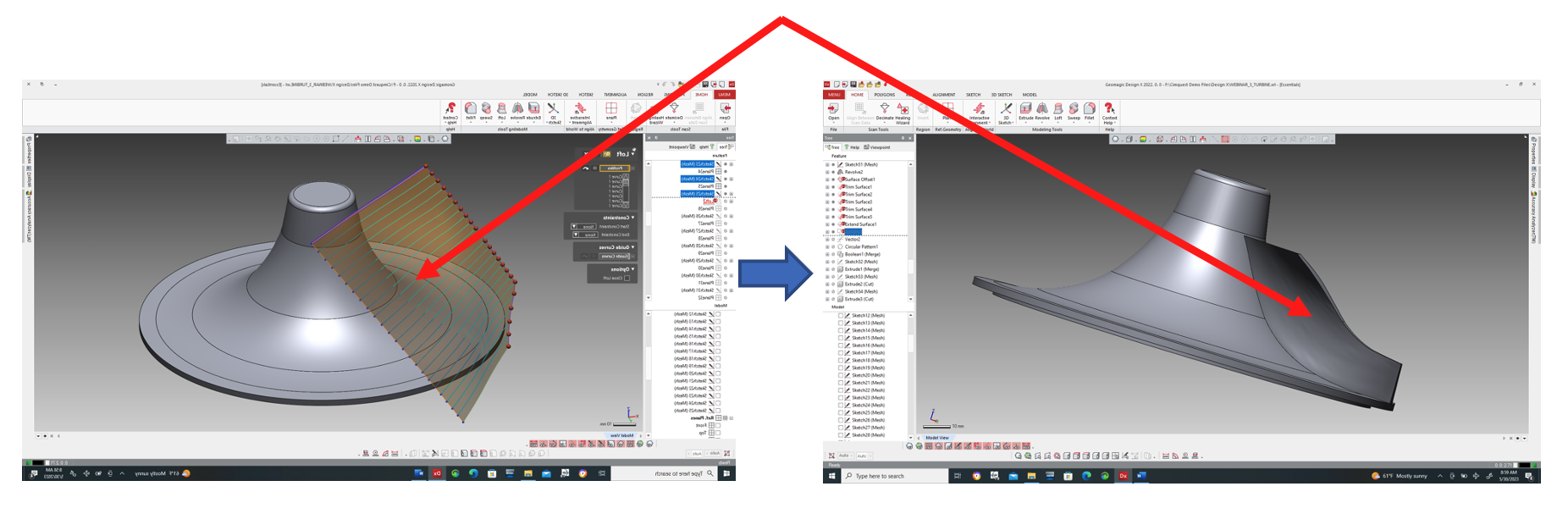

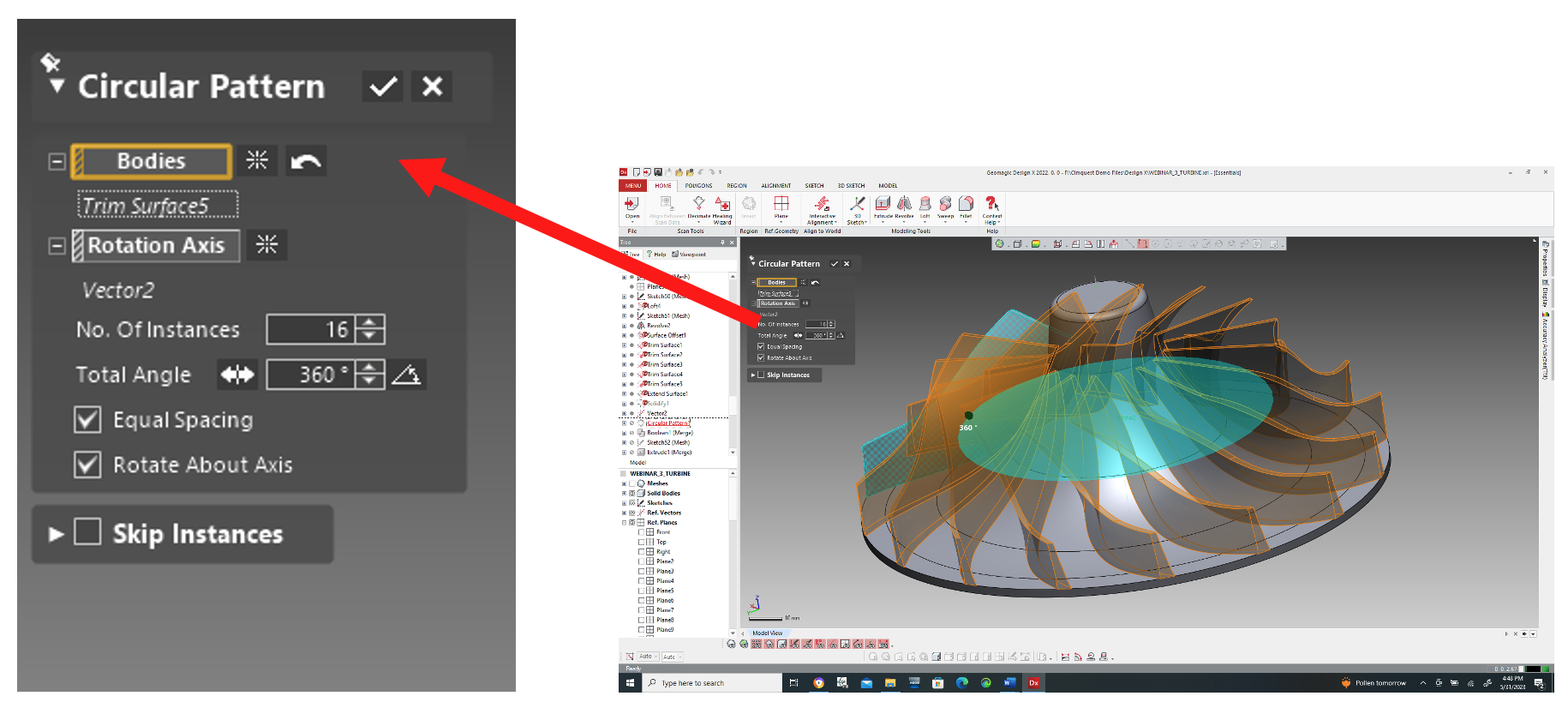

Loft Example for the creation of a blade – Curves get extracted from the scan to form the Lofted Surfaces, then Design X Essentials provides routines that may be used to trim and then Solidify the closed and bounded surface region into a solid blade.

And applying a circular pattern gets to the final machinable model.

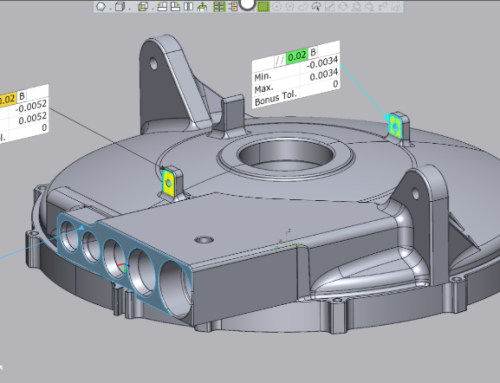

Design X Essentials can produce extremely complex surface models as well. The point cloud below was generated by a portable arm scanner, representing the surface cavity for an extremely complex propeller blade mold. The cavity shape point cloud scan shown below did not have a single flat surface, yet using advanced modeling tools, Design X Essentials was able to create the mold cavity to exactly match the scan.

Regardless of whether your shop does basic 2-axis milling and turning, 3-axis simultaneous, surface machining, 4th and 5th axis positioning, or full 5-axis complex surface machining, Design X Essentials can take scans of physical parts and will facilitate the creation of fully functional CAD files for machining.

Design X Essentials will be demonstrated at our upcoming Mastercam Rollouts! Be sure to reserve your spot!

Leave A Comment