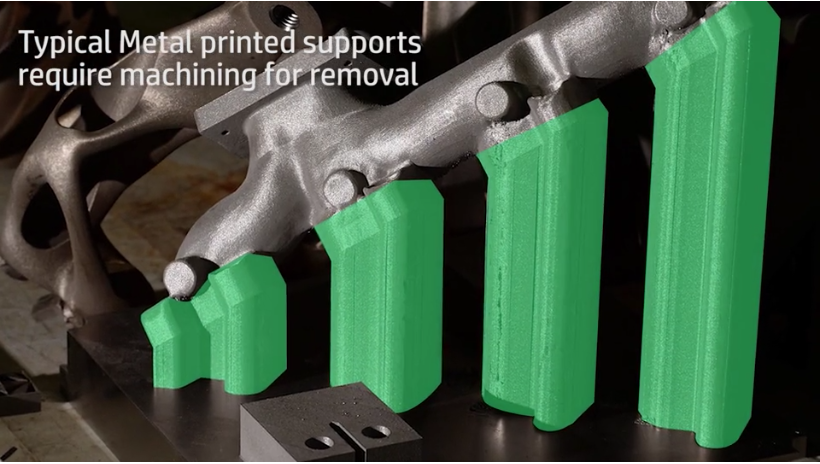

The Desktop Metal Shop System is the world’s first metal binder jetting machine and it’s designed with the modern machine shop in mind. The Shop System offers superior surface finish and resolution on metal parts and it does this without the labor-intensive support removal required with traditional metal systems.

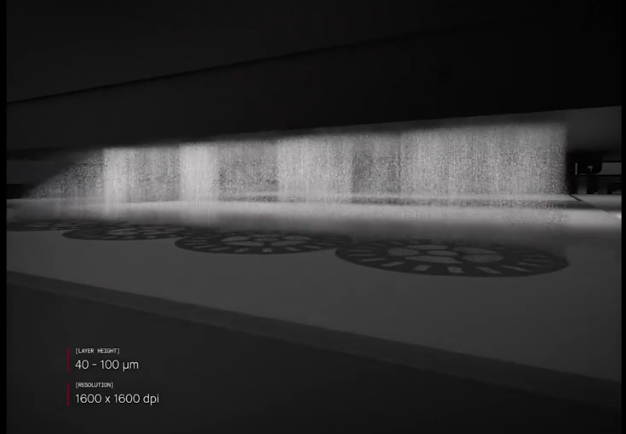

To begin the printing process, the printer spreads metal powder across the build bed. Next, it precisely jets a binding agent to bond loose powder and define part geometry.

Once the layer is complete, the build bed lowers and a new layer of powder is spread. The process repeats until the build volume is packed with bound parts. The surrounding loose powder serves as the support material throughout the build.

Once a build is complete, the build box is removed and placed in a drying oven, followed by powder station for bulk and fine depowdering. Loose powder is recovered through a built-in recycling system.

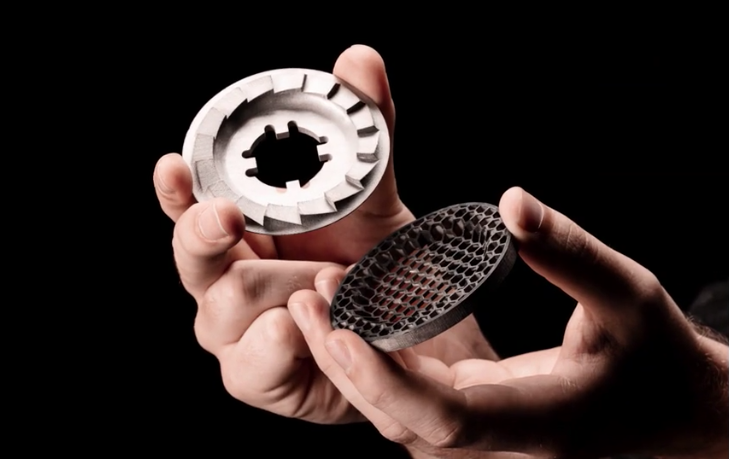

In the final step, parts are placed in a shop-safe furnace for batch sintering. After cooling, the parts are hand removed from sintering setters.

This hand removal eliminates Hours of machining off supports typical to laser-based systems. Final parts are fully dense and near-net shape right out of the furnace.

Benefits

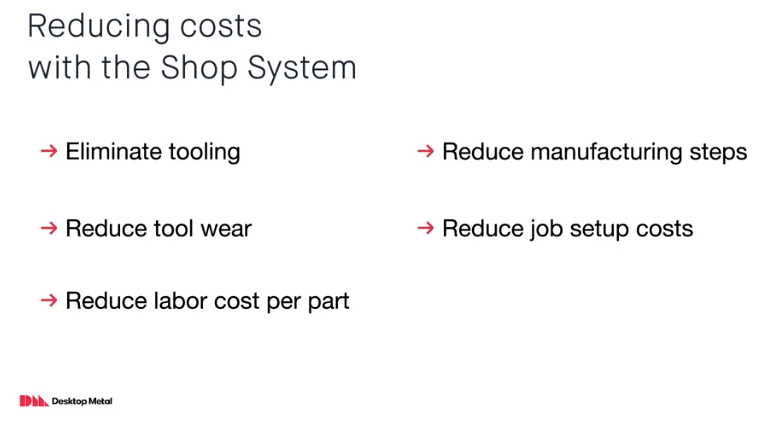

Machine shops can reduce costs with the Shop System by eliminating tooling, reducing tool wear, and reducing labor and job setup costs.

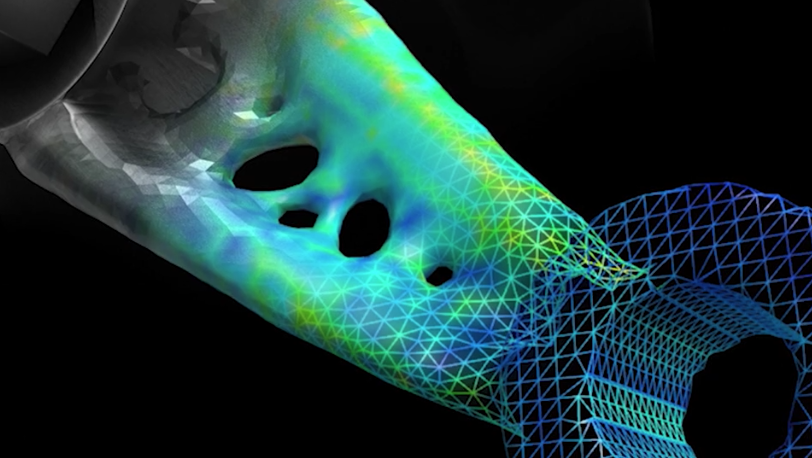

Shops can use design optimization to produce previously unattainable geometries, allowing them to take on new types of jobs. It can also free up CNC capacity for larger jobs and make small/medium size jobs economical.

Materials

The system can use a range of traditional metal powders including stainless steels, tool steels, and super alloys. It will also have the capability to print higher strength metals that are harder to machine metals like Inconel and tool steel H13.

As you can see, Desktop Metal’s Shop System is a great supplement to a shop’s arsenal of CNC machines. It can open the path to metal 3D printing, which in turn can open new types of business and put companies at a major competitive advantage. Click below to be taken to the product page.

Leave A Comment