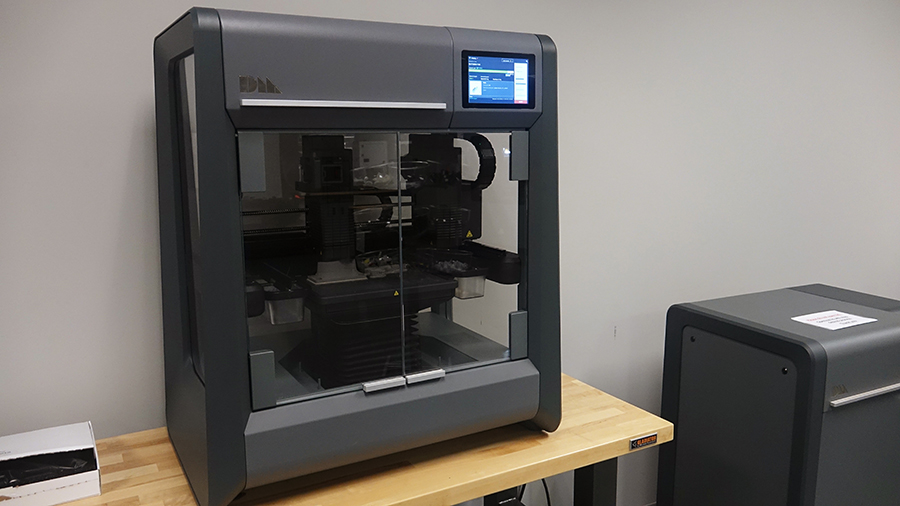

We are very excited to announce the arrival of our Desktop Metal Studio Machine and Debinder. Upon adding metal 3D Printing to our arsenal of Advanced Manufacturing Technology solutions, we fully intend to leverage our decades of experience supporting manufacturing in the region via conventional tooling processes such as CNC Machining. Our ability to process metal parts will be invaluable as we work closely with our customers to target and develop key applications for Desktop Metal’s Bound Metal Deposition Technology. For example, in cases where parts need to hold tighter tolerances then the “as sintered” specifications, or a better surface finish might be required to produce injection mold tooling such as mold inserts, Cimquest can utilize our 3 and 5 axis Takumi & Hurco CNC Mills for post-machining.

An end-to-end solution

The Desktop Metal Studio System is a three-part solution that automates metal 3D printing. Tightly integrated through Desktop Metal’s cloud-based software, it delivers a seamless workflow for printing complex metal parts in-house—from digital file to sintered part.

Unlike laser-based systems that selectively melt metal powder, the printer extrudes bound metal rods—similar to how an FDM printer works. This eliminates the safety requirements often associated with metal 3D printing while enabling new features like the use of closed-cell infill for lightweight strength, in addition to the unparalleled design freedom Additive Mfg. enables.”

Please contact us to discuss low-cost, metal 3D Printing and to schedule a tour of our Additive Manufacturing Showroom & CNC Lab. Click the button below for more information or to get in touch with us.

Leave A Comment