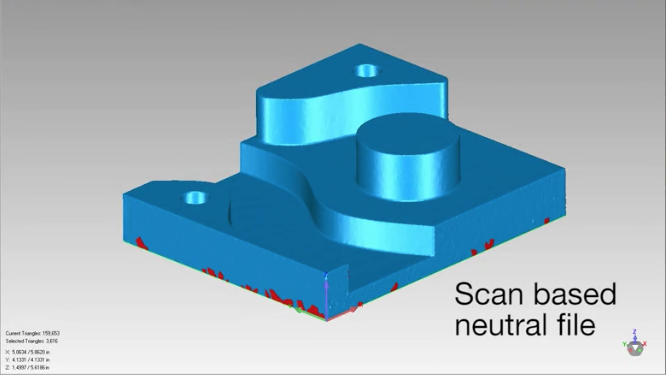

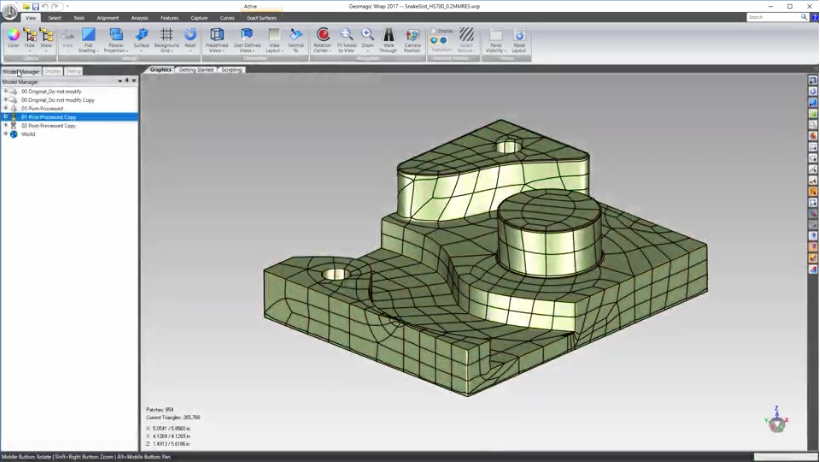

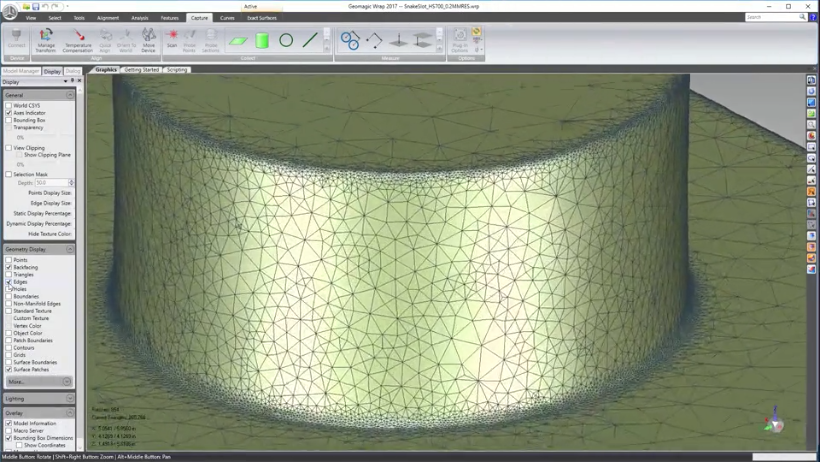

Scan-based files involve cleaning up the scan, optimizing the mesh quality, and ensuring that the scanned mesh is watertight. At this point we can generate the neutral file based on this processed scan data.

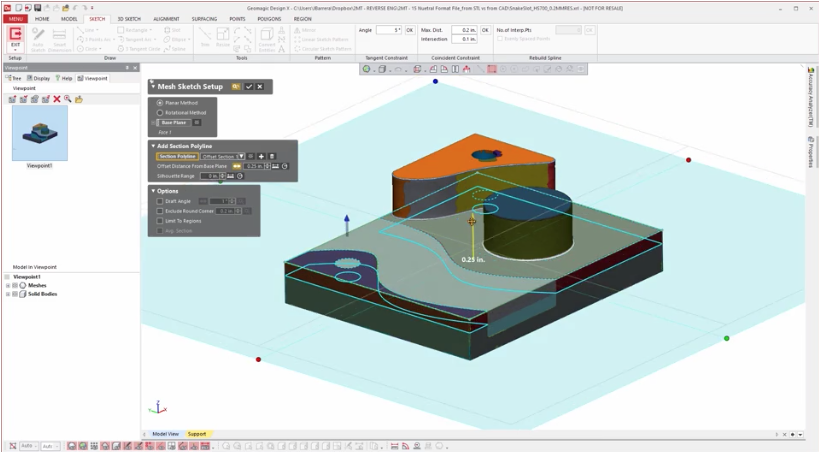

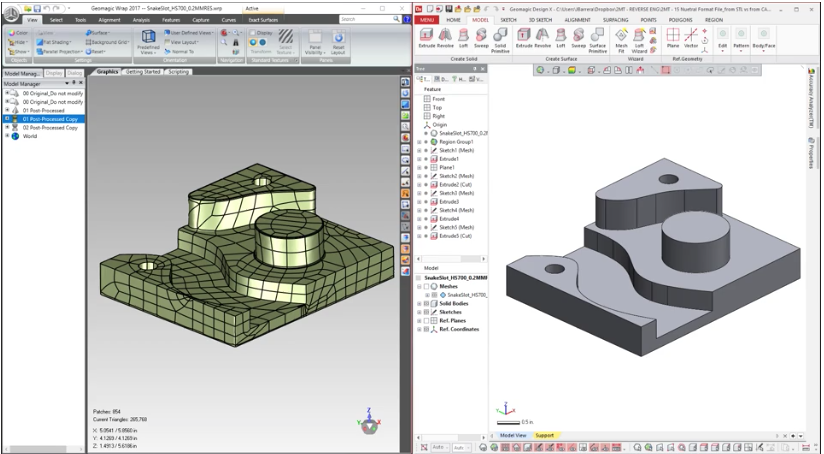

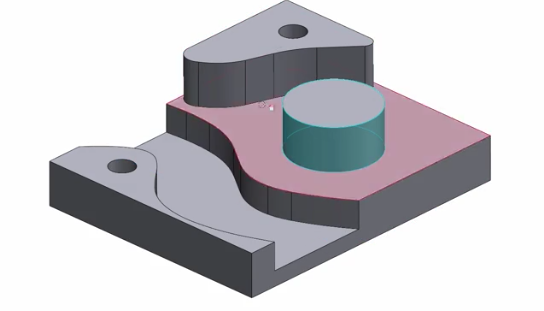

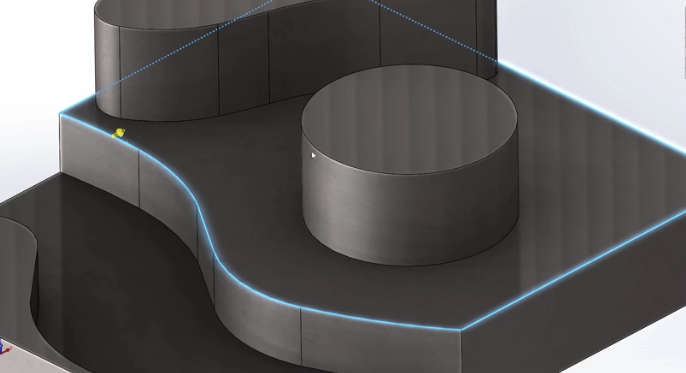

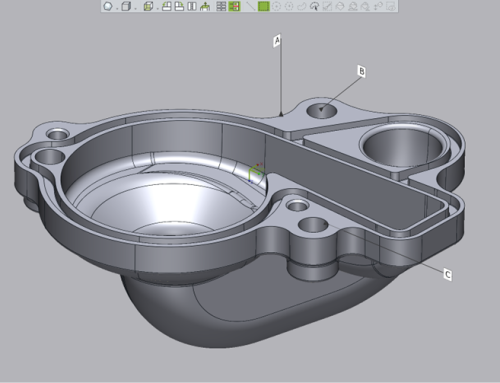

CAD-based is bit more labor intensive. It involves interrogating the mesh, creating CAD sketches and CAD features and fitting them to match the scanned data. Once the scanned data has been recreated as CAD data, we can then generate the neutral file based on the final CAD geometry.

Let’s analyze the differences between the two.

The main difference between these two approaches is that a CAD-based neutral file is able to preserve the true geometric features of the scanned part. This means that a cylinder would remain a true cylinder. The same would apply for planar faces, cones, and spheres.

This would allow you to create and leverage construction geometry, such as planes, axes, and faces. Being a true CAD shape, any sharp edges on the original part would also be preserved.

In summary, if you are looking to preserve geometric features, use the file for 2-axis machining on prismatic parts, or plan on modifying a neutral file in CAD, a CAD-based neutral file would be the best option.

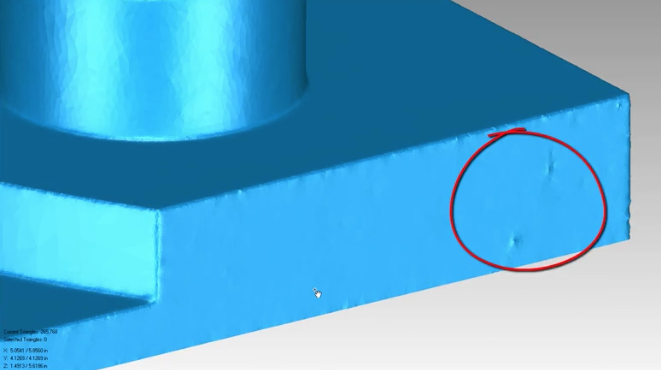

Alternately, if you are looking to 3D print a replica of a part, use the neutral file for a fit check or an interference check in CAD, or even machining 3-dimensional surfaces, a mesh-based neutral file will usually suffice. You should keep in mind that sharp corners will be replaced by small triangles, giving the appearance of a filleted corner.

Also, if the object being scanned contains any imperfections, wear or damage, these will automatically transfer over to the neutral file as well.

As you can see, both approaches produce great quality neutral files and both approaches start from collecting geometry from our 3D metrology scanners. Which approach to take depends completely on your needs and your objective.

Do you have a project in mind for Cimquest to assist you on? Reach out to us, and we will help you obtain the data that you need, in order for your project to succeed. Please contact us by clicking the button below.

Leave A Comment