Rigid Resins: Strong, Stiff, Stable

From prototype to production, Formlab’s expanding library of materials supports you at every step of the journey. Their latest materials, Draft Resin and Rigid 10K Resin span the breadth of this portfolio and expand what is feasible with SLA materials.

Rigid 10K Resin for Rigid, Strong, Industrial-Grade Prototypes

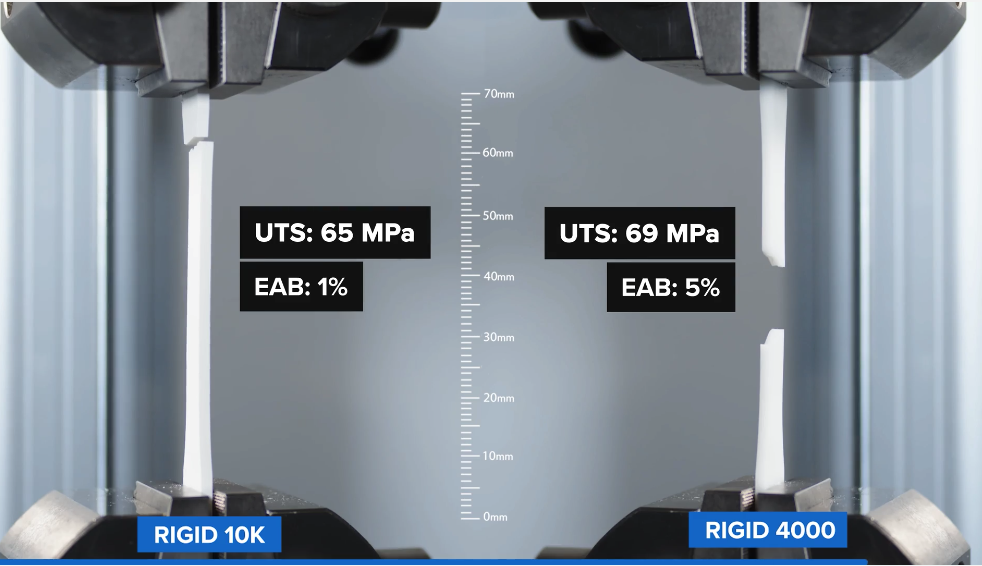

Introducing Rigid 10K Resin, the stiffest material in the Formlabs engineering portfolio. With a stiffness simulating that of glass and fiber-filled thermoplastics, Rigid 10K Resin is a glass-filled material designed to maintain structural integrity under any condition.

Consider Rigid 10K Resin for extremely stiff and strong industrial-grade parts such as short-run injection mold masters, aerodynamic test models, and heat or fluid exposed components.

Rigid 4000 Resin for Stiff, Strong, Engineering-Grade Prototypes

Glass-filled Rigid 4000 Resin simulates the stiffness of PEEK and prints with a smooth, polished finish. It is ideal for stiff and strong parts that can withstand minimal deflection. Consider Rigid 4000 Resin for general load-bearing applications like mounts, rackets, and thin-walled parts.

Print Even Faster With Improved Draft Resin

Bring products to market faster by leveraging Draft Resin early in the design process. This reformulation prints up to 4 times faster than Formlabs Standard Resins, allowing you to iterate quickly and test multiple designs in a day. Whether you are printing large parts or batches of smaller parts, Draft Resin ensures maximum efficiency and throughput without compromising part quality.

For more information on Formlabs materials, please click the button below.

Leave A Comment