METAL AND PLASTIC

3D Printing is changing the way products are designed, developed, tested, and manufactured.

From entry-level 3D printers to industrial systems, we have the tech to help you produce conceptual & functional prototypes, end-use parts, models, manufacturing tooling, jigs & fixtures, and more.

CUSTOM SERVICES

We are very focused on our customers because we know that our success depends on your success.

We have made it our mission to ensure that you not only get the right product for your needs but also that months and years into the ownership, you continue to be successful with it. We offer:

- 3D Printing

- 3D Scanning

- Reverse Engineering

- Design

- Custom Post Processors

THE PRODUCTS WE REPRESENT

We offer a wide range of products and services in the design and manufacturing industry. No matter what your manufacturing challenge is, we are here to provide you with the best solution.

IN-PERSON & REMOTE TRAINING

In-person Mastercam & Geomagic Classes

Our classrooms generally hold a maximum of 8 students. We strongly believe that our small class sizes are essential to ensure maximum instructor/student interaction and greater student success. Each student works on his/her own computer, and there is a great focus on hands-on learning. All software classes are taught on the latest version.

Remote Mastercam Classes

Years before the virus situation changed our world we were doing remote virtual online training for customers. This remote option saved time driving and money on travel costs. We have invested in new technology and instructors to ensure a learning experience as if the instructor were there looking over your shoulder guiding you.

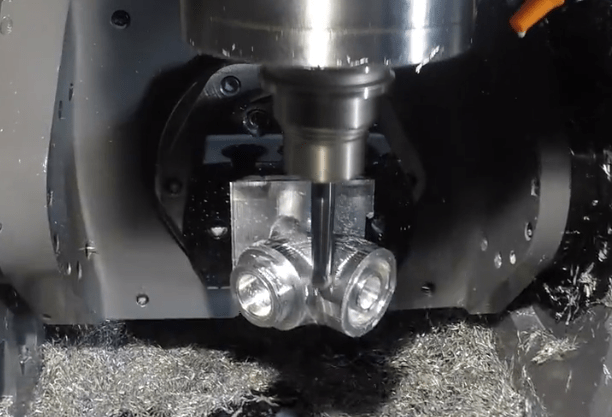

Applications Training

Our High-Efficiency Milling class is an intense course on how to implement, evaluate and select components for high-efficiency milling to get shorter cycle times, reduce tool wear, and extend machine life. Students will learn guidelines for selecting key components with hands-on interactions to build their ability in identifying and creating an efficient milling process.

OUR LATEST 2 MINUTE TUESDAY VIDEOS

Two Minute Tuesday is a popular video series from Cimquest TV. These weekly videos focus on various topics in the manufacturing industry. Every Tuesday you’ll find a new, informative video from the Cimquest Team covering Mastercam, a variety of 3D Printers, CAD, Reverse Engineering & Inspection solutions, as well as Customer Spotlights, Tips & Tricks, What’s New, and much more. Sign up today so you don’t miss out.

Sign up for 2 Minute Tuesday's |

THE LATEST ARTICLES FROM THE BLOG

We post three new articles every week that covers the latest Cimquest, Mastercam, and 3D Printing happenings, product offerings, and update info along with general Industry trends and breaking news.

Save Money With a Tax Break

Most successful businesses take advantage of legal tax incentives to help lower their operating costs. Did you know that you can immediately deduct the full purchase price of qualifying equipment and/or software? Section 179 of the IRS tax code lets businesses do just that. Much of the equipment businesses purchased [...]

Announcing the Winners of our 3D Printed Holiday Ornament Challenge

The Social Media voting on our 3D Printed Ornament Challenge ended last week and we are happy to announce the winners. Congratulations go to . . . Marcus Mitchell from New York - 1st Place Marcus will receive a $500 Amazon gift card for his "Wishing You a Toyful Holiday" [...]

Desktop Metal End of Year Trade In Offer

Desktop Metal is offering an end-of-year trade-in promotion on a new Studio or Shop system on orders received by December 17th with delivery by the end of 2021. To qualify for this promotion the MSRP of the equipment replaced (at the time of original purchase) must be at least equal [...]

Xact Metal Announces the XM200G 3D Printer Series

Xact Metal, the developers of affordable metal 3D printers, recently launched their new XM200G 3D Printer. The XM200G is built on the Xact Metal XM200C metal AM machine but uses a high-performance galvanometer system. This new architecture allows faster manufacturing times and supports multiple lasers and utilizes metal laser powder-bed [...]

HEAR IT FROM OUR CUSTOMERS