The value of functional prototypes

Picking up where we left off on our article about “How HP Jet Fusion 3D Printing customers shorten their time to market” today we will discuss the value of functional prototypes.

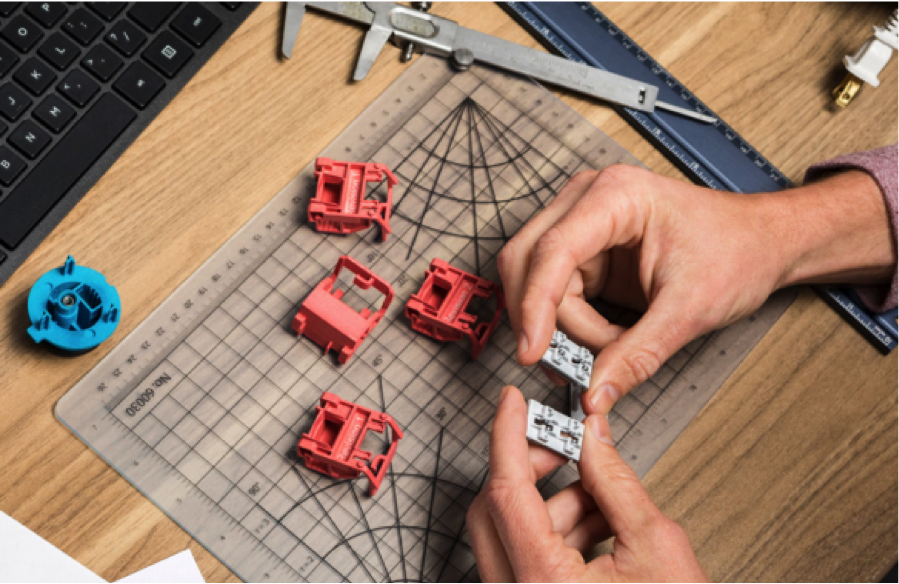

In addition to print speed, the material properties of parts from HP Jet Fusion 3D Printing Solutions are ideal for prototyping and enable customers to make decisions about their final parts.

HP Multi Jet Fusion technology allows for the creation of highly isotropic parts, or parts that have similar properties when measured in the X, Y, and Z dimensions.

“Isotropy is important so that the designer does not need to take the time to communicate extra design intents, like where strength and dimensional accuracy are most important in the part,” says Boyes. “In other additive processes, it is important to orient the part such that the strength is not needed between layers. In terms of strength, parts produced with HP MJF technology are not as sensitive to orientation, so less time is spent from engineering to getting the parts in hand that can be used in production.”

Furthermore, HP prints with engineering-grade thermoplastic and has the capability to print with high dimensional accuracy. This enables customers to create parts that can undergo rigorous design tests to test for final fit and form and ultimately prepare for production with fewer design iterations.

Stay tuned to part three of this article where we get into the color capabilities of the HP Jet Fusion 3D Printers.

Leave A Comment