Nexa3D announces the immediate availability of 3843-xABS Black Material for durable prototypes and functional production parts powered by Loctite™ high-performance materials.

Nexa3D, the maker of ultrafast stereolithography production 3D printers, recently announced that they entered into a partnership with Henkel to develop and deliver a family of co-branded performance photopolymer materials through its expanding Nexa3D channels globally. Nexa3D joins Henkel’s open platform of material partners with a focus on jointly addressing high throughput industrial production opportunities leveraging its leading print speed, large build volume and intelligent resin management technology to convert Henkel performance resins into functional parts on its NXE400 3D printer.

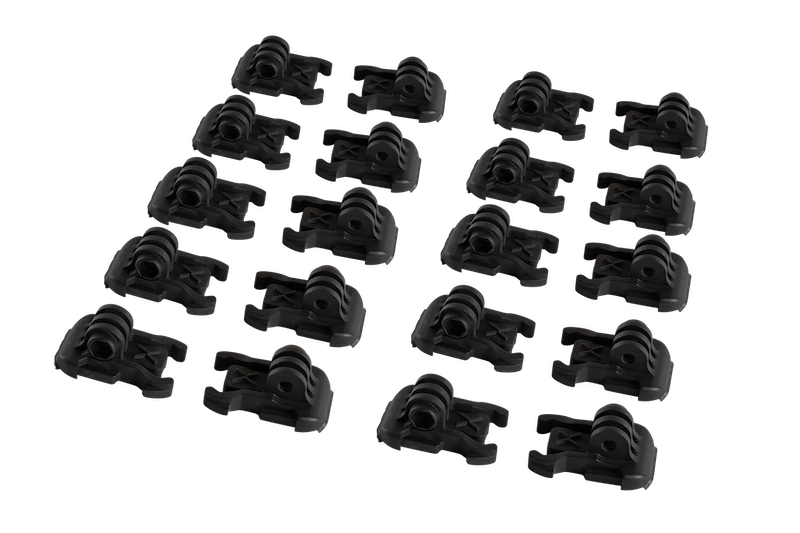

Nexa3D 3843-xABS Black is a high performance, high modulus material that boasts excellent flexural and tensile physical properties with a relatively high degree of elongation. xABS Black displays high green strength and excellent heat deflection temperature, enabling it to print accurately and function in a wide variety of applications including mechanical assemblies for robotics and automation machinery, bracket, levers and arms for manufacturing stations, and a variety of drones and last mile transportation vehicles parts and assemblies.

See the combined power of the NXE400 and xABS Black 3D printing in action in the video below.

Nexa 3D sought to partner with Henkel because of its demonstrated capabilities to rapidly and successfully develop and commercialize a variety of functional materials that overcome the limitations of conventional photopolymer resins used in 3D printing. Both companies are planning to tailor more of Henkel’s expanding portfolio of 3D printing resins to the NXE400 for the benefit of designers and manufacturers seeking to create truly functional parts, across a wider range of applications.

“We are pleased to partner with Nexa3D as our Loctite Industrial Product portfolio of PhotoPlastic and PhotoElastic materials are well suited for the high throughput of the NXE400 system,” said Simon Mawson, Ph.D. Head of Additive Manufacturing at Henkel. “The Nexa 3D team have a proven track record of delivering robust solutions and I am confident our combined partnership will deliver the production tools, materials, and flexibility the industry demands.”

“Partnering with a great global powerhouse of the caliber of Henkel represents orders of magnitude of progress in our collective abilities to deliver additive manufacturing solutions that push the boundaries of what’s possible with 3D printing for manufacturing,” said Avi Reichental, Co-founder and CEO of Nexa3D. We very much look forward to a long and prosperous relationship with Henkel making industrial-scale 3D printing a reality for manufacturers around the world.”

Please join us on Wed, Apr 29, 2020 at 11:00 AM EDT for a free webinar on Nexa3D 3D-Printing Material Advancements. Discover when, why & how to best utilize Nexa3D’s 3D-printing materials for your prototyping, tooling, and end-use applications — including its latest engineering-grade resin, 3843 xABS-Black. Register for this event at the button below.

Both the NXE400 and the xABS Black material are immediately available for purchase. Please click the button below to see all of the Nexa3D materials.

Leave A Comment