Let’s take a look at the new ultra-fast 3D printer from Nexa 3D, the NXE 400. Engineers are always looking to get their designs to market faster. While 3D printing has accelerated product development, most traditional platforms are still fairly slow for large parts and batches. The NXE 400 3D printer brings revolutionary speed to engineers with the ability to print 1 vertical inch every 2 1/2 minutes. Let’s dive into the process.

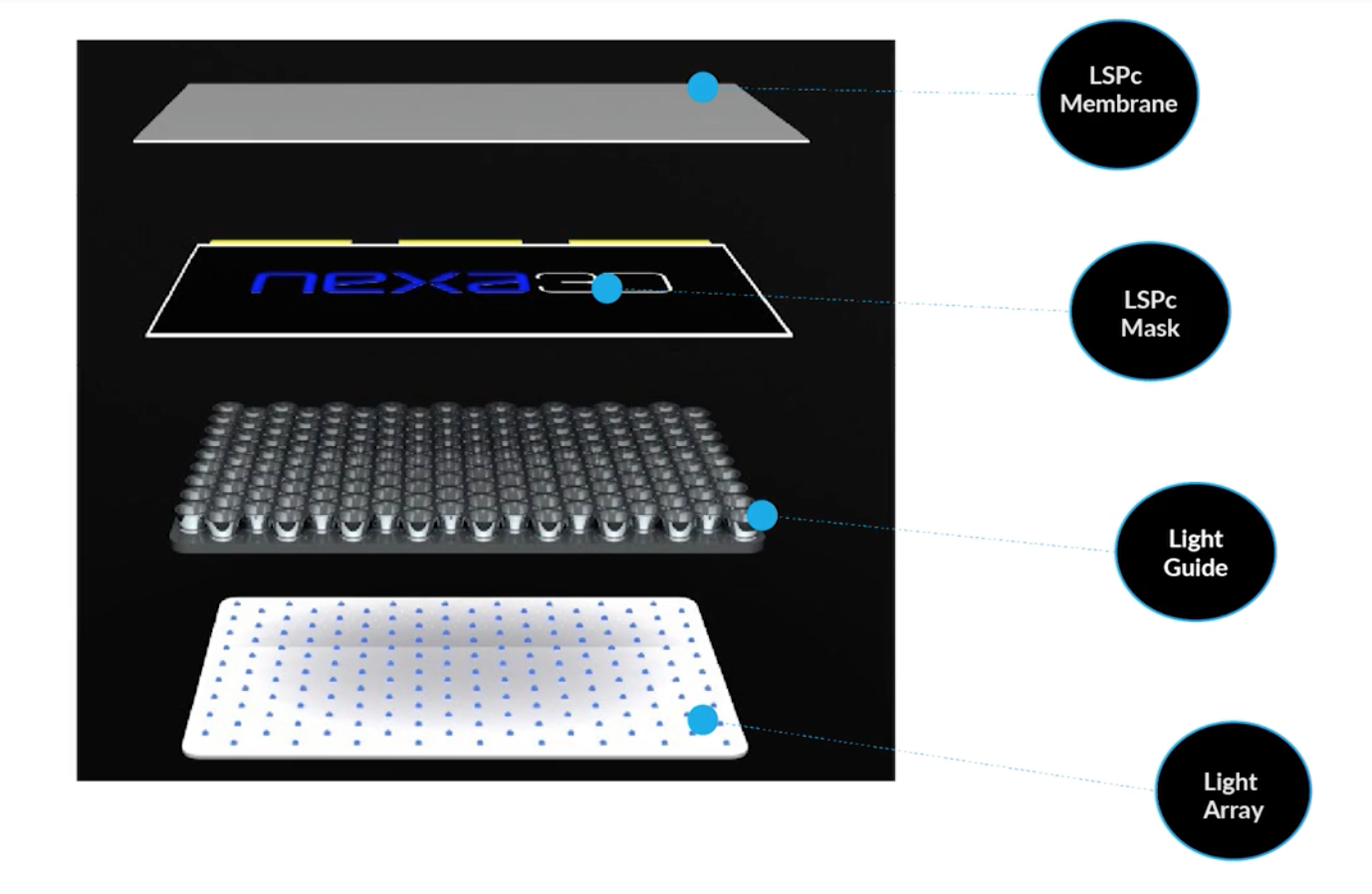

To begin, this platform is based on a unique process called Lubricant Sublayer Photo-curing, or LSPc.

It starts with the rapid projection of light from an advanced LED matrix engine, which channels through light guides to ensure uniformity across the build area. From there, the light travels through an LED mask where it gets pixelated, ensuring edge-to-edge part consistency and accuracy.

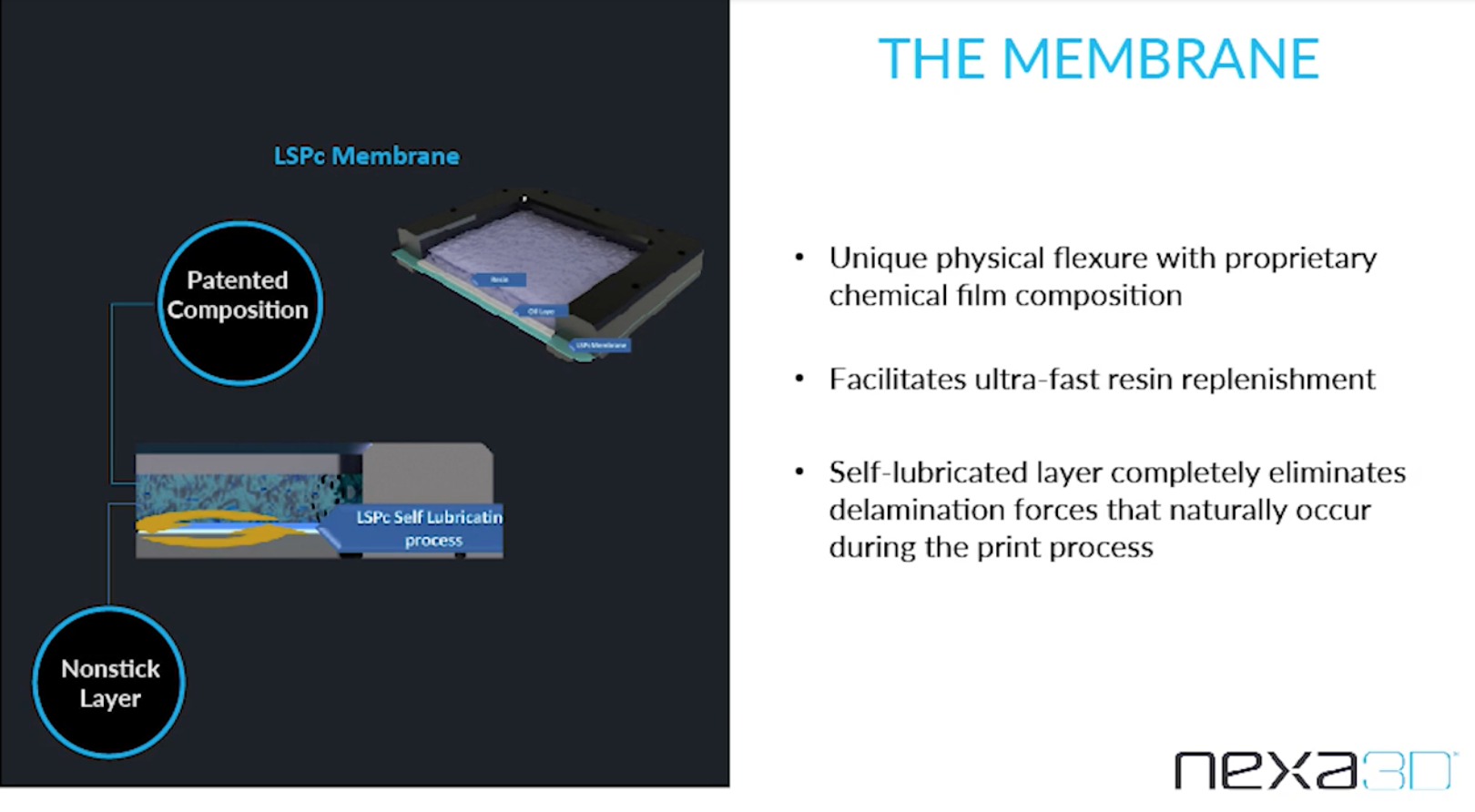

The final leg of the process entails a flexible, self-lubricating membrane that allows each printed layer to solidify while suspended. This completely eliminates the need for traditional extraction tilting. Thermal management is integrated as well to overcome the heat build-up from high-speed printing.

The combination of all this enables the NXE 400 to vastly improve your cycle times. And since the speed of output is based on vertical height, your total print time will remain the same regardless of the quantity of parts in the build.

In terms of output, parts produced on the NXE 400 are near injection molded quality with sharp angles, smooth surfaces and perfectly round holes.

It also features an open materials platform, to accelerate the rollout of new and more complex material options.

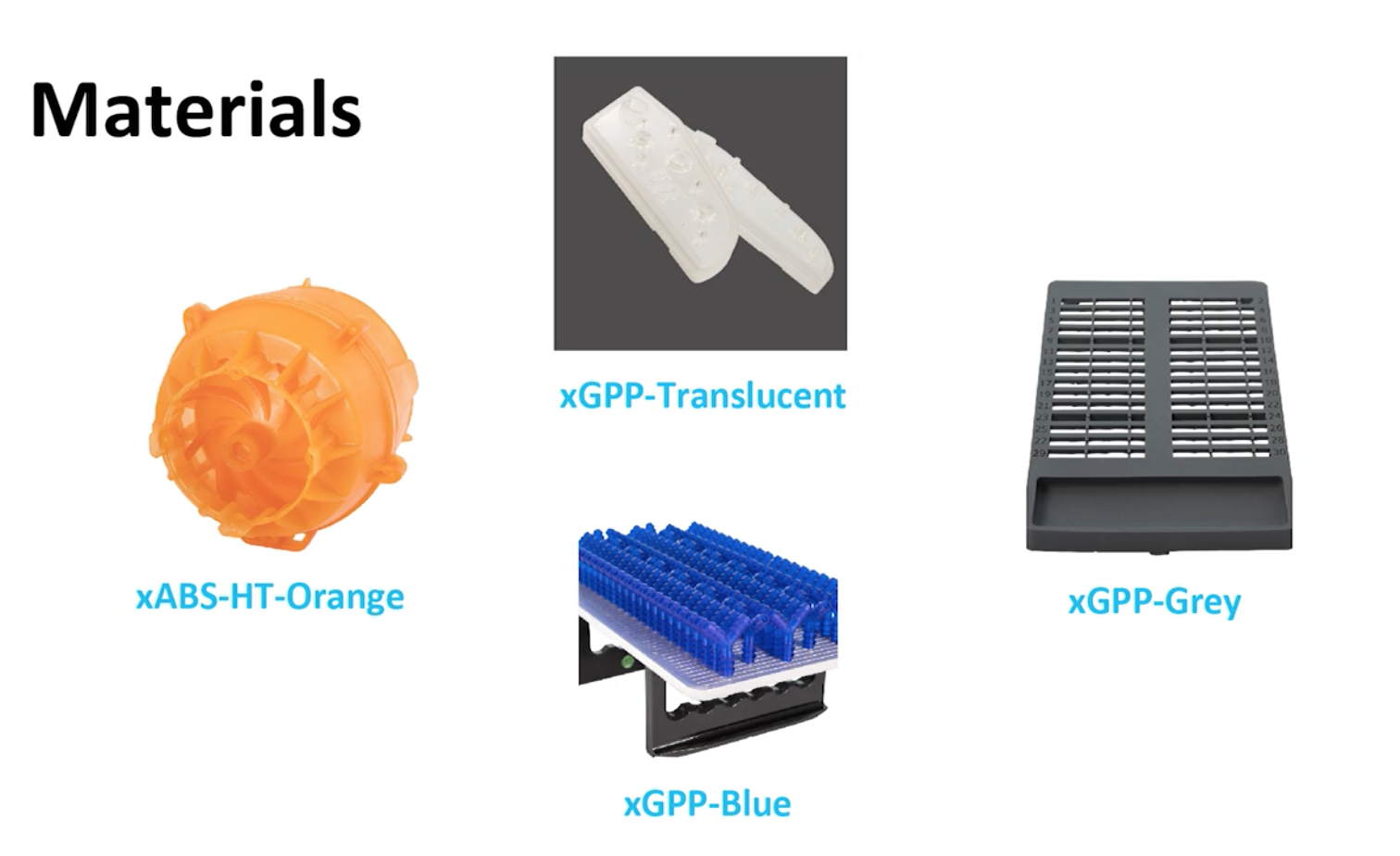

The current lineup of materials are ideal for concept modeling, functional performance testing, and manufacturing tooling.

For additional efficiency & user-friendliness, the integrated solution will have automated post-cleaning & curing units available in the near future that’ll further optimize the quality of output & ensure material properties are fully realized.

As you can see, Nexa3D’s solution is ideal for teams who are in need of producing large models or high volumes of parts in quick-turn fashion on a consistent basis. For more information about the Nexa3D printers, please click the button below.

Leave A Comment