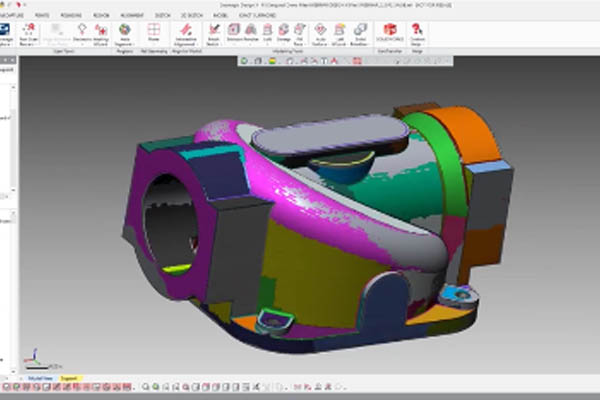

Geomagic Design X Reverse Engineering Features

This blog post will compare two modeling tools in Geomagic Design X, the Sweep and Pipe Wizards. Modeling wizards are intelligent tools used to extract 2 or 3-dimensional sketches, profiles, and features, from 3D scan data. They help users perform tasks in an automated fashion, tasks that would otherwise be very complicated to perform manually. Let’s take a look at the Sweep wizard. This tool quickly extracts sweep objects from a mesh. It intelligently computes [...]