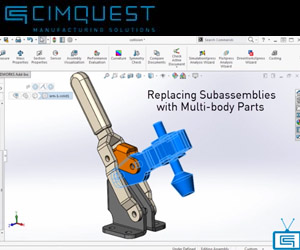

SolidWorks 2016 – Replacing Sub-assemblies with Multi-body Parts

Today we will explain how to replace subassemblies with multibody parts, a new function in SolidWorks 2016. Unlike previous versions of SolidWorks, in 2016 you can use a multibody part as a simplified representation of the assembly. When you make changes to the subassembly and save an updated multibody part, this version can replace the older copy without having to recreate the mates. Consider the assembly shown above. It contains two individual parts and two [...]