Desktop Metal Reduces Product Development Time by 25%

Desktop Metal Case Study: Virginia-based startup Lumenium finds opportunity to reduce product development timeline by 25%. Lumenium (a Desktop Metal customer of Cimquest) develops an innovative family of internal combustion engines. Their Inverse Displacement Asymmetrical Rotational (IDAR) engine is a novel and totally singular design for producing powerful, efficient, internal combustion. For Lumenium, the ability to quickly iterate on part features and designs is critical for time to market and engine performance. With the Desktop Metal Studio System, they can bring affordable metal 3D printing in-house and realize faster design iteration and functional prototyping. Download the case study by clicking the button below. Download Case Study

Request a Free Sample Part

Cimquest is testing the Formlabs materials and, for a limited time, we will provide you with a complimentary sample printed on the Form 2 Desktop SLA 3D printer and ship to you for immediate assessment. You’ll not only be able to visualize what’s realistically achievable with the Form 2 technology, but determine quickly if your chosen resin will meet or exceed your specific application requirements. Just click the button below to be taken to an online form where you can submit your request. Request Sample

Rize 3D Printing – Jigs & Fixtures

The Rize One is a machine capable of producing engineering grade parts and it eliminates many of the headaches associated with post-processing. Tooling, jigs, and fixtures are essential components of the manufacturing process. They serve as the supporting cast, helping with everything from aligning and holding product components, to assembling and testing sub-assemblies at all stages of production. In product design, as processes improve and new iterations are introduced, it is common for new tooling to be needed on very short notice. This also holds true for machine shops and assembly houses who receive customized orders for low volume production. Traditional tooling is made primarily of metals to ensure strength, stability, and durability. However, these can be timely and expensive to fabricate, especially for intricate components and one-off parts. If changes are made to a design, the tool has to be reworked and in many cases, refabricated completely. The Rize One offers an on-demand solution for printing jigs & fixtures. The moment a new iteration or project calls for updated tooling, a part can be produced in a matter of hours. Supports break away manually so there is no need for a water bath. Since Rize's process creates parts with higher Z strength [...]

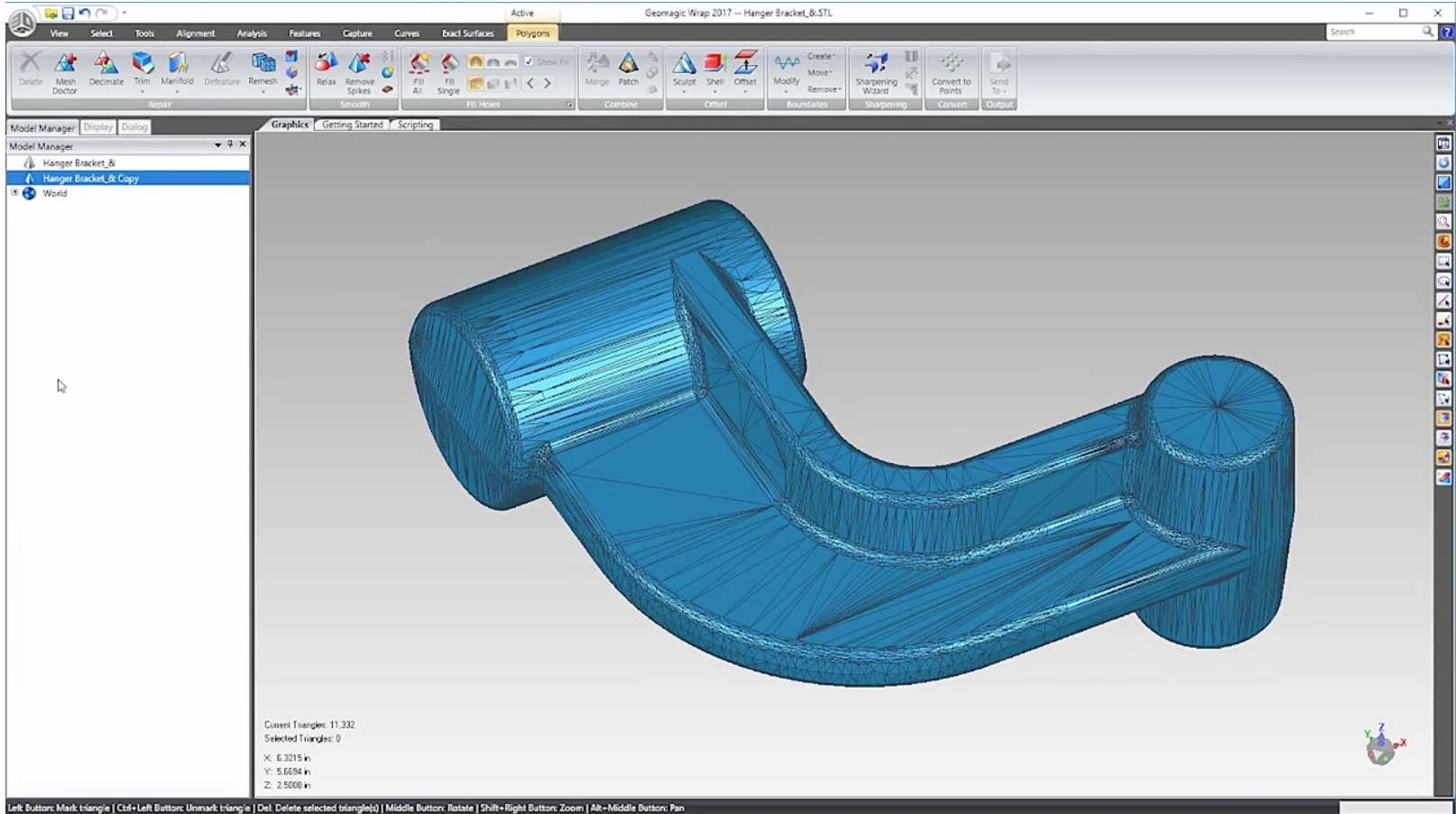

SolidWorks 2018 Importing STL Files

Today we are going to give you some tips and tricks using SOLIDWORKS 2018 when importing STL format files. The STL format file, or “Stereolithography” format, was developed by 3D Systems, and has been around since 1987. In these past three decades, it has been widely used in rapid prototyping, as well as in the 3D Printing industry. As for SOLIDWORKS, it has the ability to import STL files. The default import setting is to import the body as a graphics body, therefore, what you can do with it is very limited. For example, you can’t get a cross-section, you can’t perform Boolean operations, nor can you create a sketch on the body’s faces. In short, it’s like having a 3D picture on your screen. However, did you know that there is a way to change that setting and import STL files either as a BREP solid or a surface body? The first step to do this is to set your system options for importing Mesh files. Go to System Options > Import, and set your File Format to STL. This is where we will change the import option to Solid Body. Now, the next time you open an STL, SOLIDWORKS will automatically [...]

Form 2 3D Printer Promo

For a limited time, you can purchase a Form 2 3D Printer bundle from Formlabs at the discounted price of $4,999. The bundle includes everything you need - Form 2 Printer, Resin Tank, Build Platform, Finish Kit, 1 general purpose resin, 1-year Professional Service Plan, Form Wash, and Form Cure (valued at $5,196). The Form 2 enables you to print precise models with stunning surface finish – significantly smoother and more detailed than other plastic 3D printing technologies. To take advantage of this special sales promotion, please call us at 866-277-8778 or email us by clicking the link below. Contact Us

Cimquest Named Top Mastercam Reseller in the World

2018 is getting off to a great start. We are so very proud to announce that CNC Software (the makers of Mastercam) has named Cimquest the #1 Worldwide Mastercam Reseller. We would just like to take this opportunity to thank you. Thank you for choosing Mastercam and thank you for being our customers. We would have no success without you and we plan to do our very best to continue our award-winning service. For more information about the Mastercam line of products, please click the button below. More Info