Designing a Space Mouse Case

At times, a customer will come to us with an idea whether it is a hand sketch, a picture, or a simple drawing with dimensions on it in hopes of creating a prototype by 3D printing it. Here, at Cimquest, we have all the tools needed to create and produce these ideas and bring them to life. To illustrate this, we have created a portable case to carry a 3D Connexion Wireless Space Mouse and USB, since there was nowhere to place the USB receiver when carrying the mouse around. We still had the molded pulp packaging, which contains the cavity of the space mouse, with a perfect fit, so our first task was to capture this geometry. We used Geomagic's Capture scanner for this task, which scans at a resolution of .007." As it rotates and scans, it aligns each scan to the next and then easily stitches them together as one clean mesh file. Next, we used Design X to reverse engineer the geometry into an editable CAD model. Once we recreated what we needed, we exported out the geometry and the Feature Manager Tree to SOLIDWORKS. In SOLIDWORKS is where the engineering happens. After completing the bottom case, we were [...]

HP 3D High Reusability PA 12

In recent years, advancements in additive manufacturing and materials science have made it possible to build stronger parts with greater complexity. With the release of new and refined engineering materials, we're seeing more and more cases of companies entering the world of production 3D printing. HP is on the forefront of materials innovation and today we'll take a look at one of their notable developments, High Reusability PA 12. High Reusability PA 12 was HP's first 3D material available with the launch of their Jet Fusion series. It is a high strength, multi-purpose thermoplastic that enables industry-leading powder reusability. With PA 12, you can produce high-density, watertight parts with balanced property profiles. Below are some of the key specifications. You can see that it has an impressive tensile strength and relatively high heat deflection temperature. This material also provides great chemical resistance to oils, greases, and alkalis. All of these attributes make it great for producing both prototypes and functional end-use parts, with fine detail and dimensional accuracy. It is also optimal for post-finishing processes. Aside from these important characteristics, PA 12 allows you to achieve the lowest cost per part, at up to half the cost of comparable extrusion-based systems and selective [...]

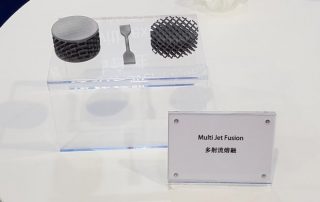

Lubrizol Introduces First 3D Printing Materials

(Reprint from https://www.tctmagazine.com) Parts manufactured in TPU with the Multi Jet Fusion process. Lubrizol, a specialty chemicals company, has introduced its first three 3D printing material products after its entry into the additive market. The Ohio-based company has followed the likes of BASF, SABIC, and Clariant into the industry to offer its expertise, particularly in the development of thermoplastic polyurethane (TPU) materials, to those pushing AM from a prototyping tool to a volume manufacturing one. Though making the announcement at TCT Asia, Lubrizol was keen to emphasize the launch of its Estane TPU soft; flexible to hard; and rigid grades were merely the start. The three materials have been developed for extrusion-based processes, but the company is also targeting Selective Laser Sintering (SLS) and, as per its involvement with HP’s Open Applications and Materials Program, Multi Jet Fusion (MJF). "Following the recently-announced partnership with HP, Lubrizol continues to expand our presence within the fast-growing space of 3D Printing,” commented David Pascual, Lubrizol Marketing Manager, in a company press release. “This event offers a great opportunity to further showcase our broad TPU portfolio aiming to serve all thermoplastic 3D printing technologies including FDM, SLS and MJF. By combining our differentiating chemistries together [...]

HP Unveils 4 Lower-Cost Jet Fusion 3D Printers

HP Inc. recently revealed the next evolution of its 3D printing business with the unveiling of four new Jet Fusion 3D printer models that will feature the same technology of the original models, but with a smaller footprint and lower cost to reach a broader set of customers. The expanded Jet Fusion lineup will include models that can print full-color objects as well as models that just do black-and-white. Capabilities include printing at high speeds—up to 52 parts in 15 hours. Pricing will start in the $50,000 range and will reach into the $100,000 range. That's in comparison to the existing Multi Jet Fusion models, which are priced in the $300,000 range. "We're expanding the portfolio. You can see we're putting a lot in place. [3D printing] is a market that's growing at a 30 percent CAGR, and we're actually accelerating the market with our entry," said Stephen Nigro, president of HP's 3D printing business, in an interview with CRN. "We see this taking off into the 2020-plus timeframe — closer to 2020 than 2025." The ultimate vision, he said, is "changing how the world designs and manufactures." Along with the lower pricing, the new Jet Fusion 3D printers differ from the original [...]

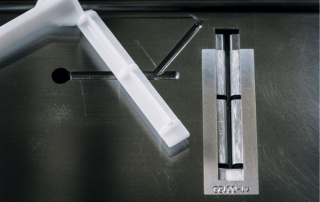

Metal 3D Printing for Injection Molding

Built-Rite Tool & Die, a Cimquest customer, is a mold-making and design firm based in Lancaster, MA. The company makes precision molds for use in a range of injection molding techniques. The Desktop Metal Studio System has been tested by Built-Rite for the manufacture of several components of the Studio System metal 3D printer. These included a “flipper arm” used in the Studio System to “eject the bound metal or interface media rods into the extruder where they are heated and deposited onto the build plate, shaping a green part.” Ron Caron, General Manager at Built-Rite, commented that “Molds must be built to withstand very high pressures. The printed inserts that we prototyped for Desktop Metal were able to pass the first round of tests and successfully molded several parts. In the beginning, we immediately saw some of the advantages of using metal printed components in our molds.” According to Caron using 3D printing allows the inserts to be produced in a quicker time, given that production could be brought in-house. Also, it was possible to design cooling channels in a new way. One benefit here was a weight saving and subsequent reduction in operator fatigue. The injection mold insert. Photo via Built-Rite. [...]

Form 2 3D Printer

Let’s take a fresh look at the Form2 3D printer from our friends over at Formlabs. Stereolithography, more commonly known as SLA, is a 3D printing technology that originated in the early 1980's. With SLA, a liquid photopolymer is converted into solid material layer by layer when exposed to a highly concentrated light source, such as a laser or projector, in a process known as photopolymerization. The result is a three-dimensional solid part that is water-tight with a smooth surface finish and fine details. Due to the high resolution, layer lines are less noticeable than parts fabricated with extrusion-based printers. While SLA fits well into a variety of applications, large-scale industrial systems are expensive to own and operate making them barriers to wide-use adoption. In 2011, Formlabs introduced industrial quality SLA to the desktop. With high-resolution, capabilities and materials previously limited to larger systems, Formlabs made SLA more affordable and accessible. Starting at $3,499 the Form2 is the third-generation 3D printer from Formlabs. It has a considerable build volume for its size with a layer resolution as low as 25 microns. One of the most exciting things about the Form2 is the impressive materials library. With a dozen materials and more to be [...]