Freeform Recreates a 2,000-year-old Face

Almost two millennia ago, a man in Roman Britain was executed by crucifixion. His skeleton was discovered in 2017 in Cambridgeshire, England. And now, thanks to the expert work of forensic imaging specialist Joe Mullins and Oqton’s Freeform software, we can see his face. Mullins is a professor at George Mason University in Virginia in the United States. He also works for the forensic imaging unit of the National Center for Missing and Exploited Children. The Producers of the BBC documentary turned to Joe for his expertise in forensics for this historic case. “It’s one of the coolest, most remarkable cases I’ve ever been involved with by far,” Mullins says. A facial reconstruction of a crucifixion victim. Image courtesy of Impossible Factual. The details of the case are gruesome. The skeleton was discovered in a cemetery within a Roman settlement. The remains were unusual in that the heel was penetrated by a nail and the legs indicated the man was bound and shackled. According to radiocarbon dating, he died between 130 and 360 C.E. and was probably in his mid-30s. DNA tests suggested brown hair and brown eyes. “They had a really captivating picture of the nail going through the heel, [...]

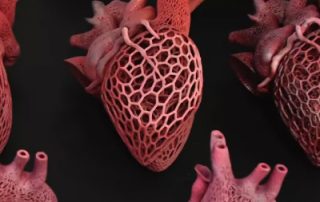

HP Collaborates with 3D Printing Artist

HP 3D printing helps to unleash new levels of creative expression from the human heart to a Triceratops HP has showcased a collaboration with Amy Karle, a leading artist, provocateur and futurist. Regarded as one of the most influential women in the 3D printing industry today and one of the BBC’s 100 Women, Amy Karle is leveraging the power of 3D printing to reinvent creating art in amazing new ways. HP’s 3D Printing & Digital Manufacturing organization and HP Labs are working together with Amy Karle to provide the most advanced 3D printing solutions to make her creative art expression a reality. “I love the exploration and development that 3D printing offers: a new opportunity for thinking, a new way to reshape what we create, and a completely new approach to expression in which digital, physical and biological systems are interwoven,” said Amy Karle. “HP 3D Printing enables me to bring this vision to life by opening up new artistic possibilities not achievable before.” Amy Karle’s mission is to positively impact others, raise consciousness and contribute to social, political, and technical development by making and sharing her work. As an artist and designer, Karle uses HP Multi Jet Fusion technologies which include the [...]

What is Electrostatic Discharge (ESD) and Why Should You Use It?

Electrostatic discharge (ESD) is commonly known as “static electricity.” These discharges occur when an electric charge is built up and then rapidly transferred from one object to another which is usually accompanied by a visible spark. An electrostatic discharge can have negative consequences, where components can become damaged or lead to unsafe circumstances. These are most commonly in (but certainly not limited to) electronics manufacturing. For example, small electronics can be destroyed by ESD with voltages lower than 10 volts of static electricity where flammable liquids or gases are handled Therefore, manufacturers must adhere to ESD protocols to avoid any possible buildup of static electricity to ensure product quality, as well as, maintain a safe working environment. These protocols might include: Equipment handled inside an ESD Protected Area (EPA) Protective gear worn by personnel to dissipate a static charge to the ground Components are protected with specialized packaging that is made from static-dissipative (AKA ESD-safe) materials Expanding on that last bullet point, a material is considered ESD-safe when it reduces the transfer of static electricity. Its purpose is to avoid any electrostatic discharge that could affect the components surrounding it. Since plastics are insulators, they have a charge and a high electrical resistance. [...]

HP Unveils Disruptive New Material for 3D Polymers Production

Accel Digital Solutions, Decathlon, Erpro Group, and Materialise are achieving unparalleled surface aesthetics and cost-efficiency in parts production HP Inc. will showcase parts at the annual AMUG (Additive Manufacturing User Group) Conference using a new material qualified for its industrial 3D polymers solutions. Developed with Arkema, the new PA 12 S material sets the standard for surface aesthetics, while reducing costs for customers using HP’s Jet Fusion 5200 Series 3D printing solutions. The reach of this pioneering material will soon expand, as it is set to become available for the Jet Fusion 5600 Series later this spring, broadening its application across HP's suite of polymer 3D printing solutions. “From design to parts production and post processing, HP is committed to delivering a broad range of innovative materials and programs for more sustainable production,” said Francois Minec, Global Head of 3D Polymers, HP Inc. “We are thrilled to once again join our colleagues across the industry at AMUG as we collectively look to accelerate scale and adoption of additive manufacturing.” Optimizing Production Costs and Efficiency with PA 12 S The introduction of PA 12 S, enabled by Arkema, is set to revolutionize the industry by reducing variable costs per part and significantly lowering the [...]

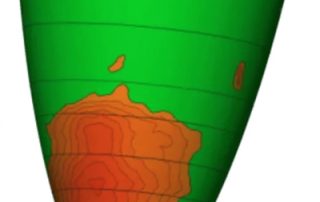

The Impossible Becomes Reality With 3D Scanning

When should you perform 3D scanning? As with other tech novelties, the unbridled enthusiasm for scanners makes it difficult to differentiate the hype from the valuable applications. Should you decide to seek out the answer in the vast online wilderness, you’ll discover some interesting passion projects and creative feats of engineering. Scanning body parts and boats seems to be a particularly popular pastime! Fun and games aside, the world of manufacturing faces growing demands: short lead times, narrow tolerances, measuring complex shapes in extreme environments (think suspended bridges!). Under such circumstances, the value of 3D scanning is clear. 3D Scanning for Inspection In particular, anyone conducting an inspection is likely to benefit from scanning due to the large amount of data that scanners can gather, the accuracy of the measurements and its non-contact nature. Two great examples of this come from SCAN IT 3D, a 3D scanning service provider and Geomagic partner that is based in Germany and Switzerland. SCAN IT 3D has worked on a range of scanning projects, from reverse engineering vintage car parts, scanning entire trains, to inspecting pipes and modeling heads... You name it, they’ve scanned it. Out of this wealth of cases, we’re going to look at two [...]

Introducing Kimya PEI Support: Simplifying Your 3D Printing Process

Introducing Kimya PEI Support, a new high-performance breakaway support filament meticulously designed to elevate your 3D printing experience. Tailored for use with Kimya PEI-9085 and Kimya PEI- 1010 filaments, both based on ULTEM by Sabic, this innovative support material brings a new level of functionality to your printing of ultramaterial parts. Perfect Synergy with ULTEM-based PEI 3D printed parts Crafted with precision, Kimya PEI Support establishes a perfect synergy with Kimya PEI-9085 and Kimya PEI-1010 filaments. The synergy ensures an optimal 3D printing experience, with the support material exhibiting excellent adhesion to the model material. This seamless integration guarantees a hassle-free printing process with consistent and reliable results. The challenge of printing intricate parts with complex geometries and internal features has met its match with Kimya PEI Support. This innovative support material opens up a new realm of design possibilities, enabling the creation of high-performance material parts that were once deemed impossible through traditional manufacturing methods. By providing essential structural support during the printing process, Kimya PEI Support prevents the collapse of model material before hardening. This not only ensures the integrity of the final product but also facilitates the fabrication of intricate designs that push the boundaries of what can be achieved [...]