Metrology Minute – Fitting Deviation

Fitting Deviation is a settable option in the GD&T family of tools available with Control X. When checking for a GD&T value, such as Flatness, this option enables you to not only see what the fit deviation is but also shows you the results in a clear unambiguous color map display. This lets you see the exact conditions of the surface and not just whether it is in or out of tolerance. For example, the Flatness GD&T callout shown below on the model lets you know that the entire flat surface is within the general model nominal tolerance allowed. If you turn on the Fitting Deviation tool, a localized color map, you will see precisely what the machined surface really is with regards to Flatness. From the image above, you can see that the center portions of the flat surface are somewhat ‘concave’ (light blue) or slightly undersized as the edges are slightly full (yellow) from the nominal CAD model, providing a slightly ‘dished’ result after machining. This could be an indication that the toolpath chosen to mill the face might need to change or perhaps the fixturing didn’t hold the part securely. This next example really shows off the power of Deviation [...]

Desktop Metal Shop System Reduces Costs and Increases Revenue

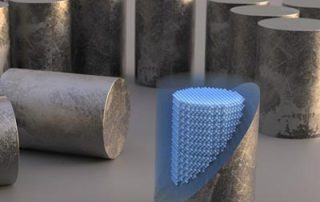

The world’s first metal binder jetting system designed for machine shops, the Shop System is capable of printing complex metal parts with the benefits that standards machine shops expect: unparalleled productivity with superior print quality while maintaining high levels of accessibility throughout the entire process. In addition to process and product innovations, exceptional productivity, print quality, and reliability, the Shop System delivers another key benefit - the ability to both reduce costs and increase revenue. The Shop System’s unparalleled productivity - as much 70 kg of metal parts can be printed in a single day - allows it to deliver per-part costs that are competitive with traditional manufacturing methods like casting and forging, making the system a viable option to produce end-use metal parts across a wide range of industries and applications. Reduced Cost The tooling-free nature of metal 3D printing means manufacturers do not need to factor tool amortization into part costs. For many quantities of parts, this leads to significant per-part savings, since tooling costs often add up to tens of thousands of dollars. While machining can sometimes be done with a significantly smaller investment in tooling, 3D printing still produces cost saving by reducing wear on cutting tools, and the [...]

Ultimaker Announces Metal 3D Printing Capability

Reprinted from Fabbaloo Metal parts made on an Ultimaker S5 3D printer [Source: Ultimaker] Ultimaker announced the “Ultimaker Metal Expansion Kit”, which enables metal 3D printing on their S5 model. Metal 3D printing is usually a rather costly affair, involving specialized equipment, metal powder, complex HVAC environments, expensive post-processing equipment, sophisticated thermal simulation software, and a squad of engineers. As a result, it can be extraordinarily expensive to undertake and is applicable to only industries where parts are traditionally expensive, like aerospace and certain healthcare applications. But there are other approaches for 3D printing metal objects. Alternative processes can be less expensive and arduous by using “cold” metal 3D printing processes or unusual FFF methods. The latter is now being officially implemented by Ultimaker. The new Ultimaker Metal Expansion Kit can transform an Ultimaker S5 3D printer into a metal printer, and it’s actually quite straightforward. The new Ultimaker Metal Expansion Kit [Source: Ultimaker] Ultimaker has partnered with BASF Forward AM to use their Ultrafuse 17-4 Stainless Steel filament. This is a specialized filament that is a mix of a binding polymer and stainless steel powder. The process used to produce metal objects is very similar to 3D printing polymer [...]

Integrating Production-level Metal 3D Printing Into a Traditional CNC Machine Shop

Based in Karnes City, Texas, PGV has more than three decades of experience manufacturing equipment for the oil and gas, aerospace and robotics, and automation industries. Along with traditional manufacturing via CNC machining, the company is now moving into next-generation processes by integrating production-level metal 3D printing into their capabilities. “We could have chosen to invest in more CNC lathes or CNC mills, but we chose to go the additive manufacturing route because energy is changing. The whole world is changing and we have to be able to pivot with it.” - Ramon Perales, President of PVG Oil Tools You can learn more about how the Desktop Metal Shop System enabled PGV to grow its business and create more agile, efficient operations by watching the video below.

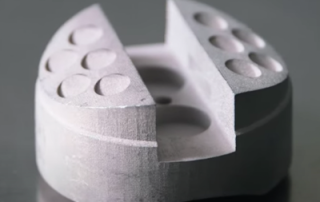

3D Printed Silicon Carbide Enables Safer Nuclear Power Generation

A reprint from Additive Manufacturing. Binder jetting provides a way to create pure silicon carbide fuel structures that can withstand the harsh environment of a nuclear reactor and provide a strong barrier against the release of radionuclides. Dr. Kurt Terrani, the executive vice president at Ultra Safe Nuclear Corporation’s Core Division, was on the team that developed a process for 3D printing silicon carbide at Oak Ridge National Laboratory. USNC licensed the technology for use in making Micro Modular Reactors. As we continue to feel the impacts of climate change, finding alternative sources of energy that don’t involve burning fossil fuels is an important part of reducing and mitigating its effects. Renewables such as wind, solar and hydro power can provide clean sources of energy, but they might not be able to provide enough power. Some scientists are now turning to nuclear as a promising source of power that doesn’t generate greenhouse gas emissions. Many of the nuclear power plants in use right now were built in the 1950s and 1960s, and are scheduled to be phased out soon. Building new plants using the same outdated technology will require large amounts of land, money and time. So researchers have begun developing [...]

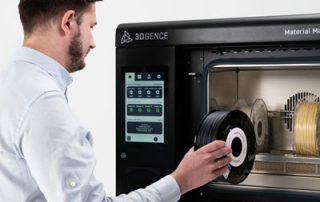

3DGence Material Management System Automates 3D Printing Material Prep

Automate the correct preparation of your materials for accurate, strong, and high-quality parts. The MMS enables connected productivity, repeatability and full traceability of the printing process. 3DGence MMS automates material storage, preparation, and post-print annealing – making successful printing of Ultra-Polymers like PEEK, ULTEM™, and Composites accurate and simplified. As the shift from prototyping to end-use parts has become a reality through industrial grade 3D printers and advanced materials, automation and pre-configuration ensures print success. Improper handling and preparation of materials can result in moisture creep, print failures, warping, and low visual quality – resulting in inaccurate parts and significantly reduced productivity. You can ensure print productivity, part integrity, and the highest quality with the 3DGence Material Management System. Some of the features of the Material Management System include: Process control and print traceability Select materials from the Certified Open Material Database and register them to get full material traceability. Each spool of material purchased from 3DGence is equipped with an NFC tag with a Unique ID. Once selected, the material is registered by scanning to the MMS and integrated with 3DGence CONNECT. The material associated to the print is traced in the print process and can be viewed on the MMS or [...]