Metrology Minute – Exporting Data from Control X for Downstream Use

Control X is capable of collecting 2D and 3D dimensional information, GD&T information, Statistical Information (RMS Value, Standard Deviations, etc.). More often than not, users are interested in displaying the data in a report, either to be used internally or to be presented to their customers. But did you know that Control X can also make this information available for downstream applications as well? Consider the “3D Dimensions” and the “3D Overall Dimensions” nodes below. The 3D Dimensions GD&T node contains three dimensions. And the 3D Overall Dimensions GD&T node contains four dimensions. With the 3D GD&T Node selected below, we can preview the data in the form of a spreadsheet, at the bottom of the graphics window. Notice pass/warning/fail information is also clearly displayed, utilizing colors. With a quick Export to CSV, the data is readily available in a standard, fully-functional Excel CSV file. We can then retrieve the CSV file and all dimensional and testing data is available for any downstream applications. Please reach out to Joel Pollet with any questions or comments.

Please Join Us at AMUG

This year’s Additive Manufacturing Users Group (AMUG) Conference will be taking place April 3-7 in Chicago. This users' group brings together engineers, designers, managers, and educators from around the world to share expertise, best practices, challenges, and application developments in additive manufacturing. AMUG is like no other industry event in that it is for the user, by the user. This is an all-volunteer-run event, and all attendees are active users of commercial additive equipment, so everyone is among peers. AMUG is a unique theme of learning and cooperation. Three people from Cimquest will be attending: Rob Hassold (CEO & Founder), Shawn Crews (President), and Dave Macfie (Director of 3D Printer Sales). In addition, Dave will be participating in the AM Equipment Benchmarking Considerations panel discussion. Joining Dave on the panel will be Ben Arnold (Massivit), Meghan Rock (Desktop Metal) & Tim Heller (Stratasys). This discussion will take place on Wednesday, April 6th in the Boulevard Room C (2nd Floor) from 4:30-5:30pm. Please let us know if you plan on attending the conference by clicking on the link below to send an email. We would love to spend some time with you at one of the several meal breaks, receptions or the panel discussion [...]

Introducing Formlabs Fuse 1 Nylon 12 GF Powder

Introducing Formlabs Fuse 1 Nylon 12 GF Powder: Stiff, Stable, Functional in-house production Glass-filled SLS powder for industrial-grade production requiring high stiffness and thermal stability. Nylon 12 GF Powder, Now Available for the Fuse 1 It’s never been easier to bring manufacturing in-house, and with new gaps and blockages in previously reliable supply chains appearing every day, it’s never been smarter. The Fuse 1 SLS printer, now with new Nylon 12 GF Powder, enables every manufacturer to take control over their means of production. Nylon 12 GF Powder is ideal for parts that require high rigidity and thermal stability, allowing companies in the automotive, aerospace, and product development industries to create industrial-grade parts in-house, instead of relying on outsourcing and raw materials being in ready supply. Use Nylon 12 GF Powder for Prototyping or small batch production of functional parts High dimensional accuracy and low warpage Parts undergoing sustained loading Dimensional accuracy at elevated temperatures Learn more by clicking below. Learn More

Cimquest Training Most Common Questions

We just added a new page to our website that answers some of the most common questions about our training options. We offer many classes, in many different locations, on many different topics and we understand that a lot of questions can arise. If you are trying to figure out which class might be best for you, or whether or not you should take a remote class versus an in-person class, or what the technical requirements are for remote learning, please check out our new page. It answers all these questions and more. Get answers to your training questions To see all the training class descriptions and our upcoming training schedule please click below. More Training Details

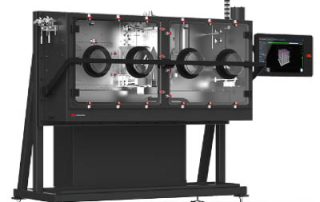

New Materials Added to Desktop Metal Production System

Continuing with our spotlights on 3D printers from Desktop Metal, today we will recap some new materials added to the Production System™. Be sure to also check out our upcoming 3D Printing Online Seminar Series which will happen over the next couple of months. Please stay tuned for more details on that and in the meantime let’s take a look at one of the new releases from Desktop Metal. 2021 was a busy year for the Production System™, particularly with the qualification of five new materials! Desktop Metal added D2 tool steel, Inconel 625, 420 stainless steel, 4140 low-alloy steel, and 316L stainless steel to the list of compatible materials. 2022 will only get busier and they already announced two new materials. High Hardness Stainless Steel (SSHH) and commercially pure Copper are now qualified for use. The number of materials you can use with the Production System™ is only increasing and the applications and industries that can benefit from the system is broadening. More details on the Production System™ via the button below. More Details

What’s New with Desktop Metal Shop System

Desktop Metal released some great additions last year and today we will spotlight some new 3D Printing materials. Many new 3D printers and materials will also be showcased in our upcoming 3D Printing Online Seminar Series which will happen over the next couple of months. Please stay tuned for more details on that and in the meantime let’s take a look at one of the new releases from Desktop Metal. New 3D Printing Materials Two new materials were released: 316L stainless steel CoCrMo alloy These materials, in addition to the already released 17-4PH stainless steel, greatly expand the capability for end-use parts. The PF1 Furnace and the High Purity Retort are also compatible with the Shop System™, granting access to the many benefits listed above. Together with updates to Fabricate® MFG, we’re excited to continue expanding the applications of the Shop System™. Keep an eye out for new materials in 2022! More Details