Control X Color Map Fitting Tolerances through GD&T

This month's Metrology Minute will focus on a capability of Control X called Color Map Fitting, which is an extremely useful ON and OFF switch to use for analyzing the results of a GD&T callout. GD&T will typically check for a specific criteria to be within an acceptable tolerance and the user is looking for a Pass or Fail response. Consider a connecting arm that looks like the one below. Where Datum A is the top large face of the part and Datum B (colored orange) is the centerline along the YZ Plane and Datum C (colored green) is the centerline along the XZ Plane. Now, let’s consider measuring the Flatness on top of the small end of the rod. When we place a Flatness GD&T callout on that face, Control X has the ability to check that the desired tolerance, within a specific tolerance, is met. Control X can also return the min and max tolerance values (see callout below). Please note that Flatness callout measurements do not need to reference datum(s). They purely check for how flat a manufactured surface is. Below we can see that the desired tolerance value based on the GD&T callout is .008” total tolerance (or +/-.004”) and [...]

A Closer Look at Desktop Metal Studio Ti64 Titanium Material

Today we will take a look at Desktop Metal's newest material, Ti64 titanium. It’s one of the most commonly used titanium alloys and Ti64 has excellent strength, low modulus of elasticity, high corrosion resistance, good weldability, and is heat treatable. It also has a high temperature resistance and the ability to withstand temperatures of nearly 800°C. Ti64 is used in a variety of industrial applications, where low density and excellent corrosion resistance are necessary, such as; aerospace, marine, power generation, and offshore oil and gas. It is also used in specialty automotive, medical device prototypes, and consumer goods. With traditional manufacturing, titanium is not cheap and it is notoriously difficult to machine. Machined parts will typically start with a large billet and a lot of material might have to be removed to produce a part. Hence little mistakes can be costly. With 3D printing that waste is all but eliminated resulting in significant savings. However, this material is not new to metal 3D printing. Due to its reactive nature, it can pose certain health and safety concerns when processed on laser-based powder bed fusion technology, which can lead to facility requirements that are expensive or prohibitive. Whereas 3D printing Ti64 titanium on Desktop [...]

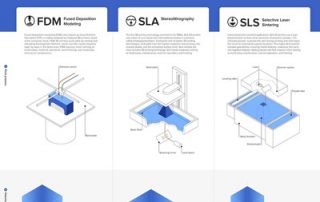

Comparing FDM, SLS, and SLA 3D Printing

reprint from the Formlabs blog In-house 3D printing can increase manufacturing speed, reduce costs, enable rapid prototyping, and facilitate innovative products and designs. The popularity of 3D printing has grown as it has established itself as an accessible alternative to traditional manufacturing. However, 3D printing is not a one-size-fits-all technology. There are three well-known types of 3D printing: Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Each method has its unique benefits. The 3D printing infographic below is provided by Formlabs and it describes the key differences between FDM, SLS, and SLA 3D printing. It provides handy visuals for each method’s print process. The results of the printed parts differ, so it shows the results achieved with the three different 3D printing technologies. It is also important to optimize your workflow and floor space to best implement a 3D printer into your office environment. Lastly, the infographic demonstrates what applications each 3D printing technology is best suited for. With this handy infographic, you can deepen your understanding of 3D printing technologies and jumpstart your decision-making process about which printer is best suited for you. (Click on the image to be taken to the Formlabs blog to view a much bigger [...]

Advantages of 3D Printing with Polypropylene

This article will cover a highly versatile 3D printing material called Polypropylene. 3D printing with Polypro offers the ability to produce prototypes in the same material as your final parts. Let’s take a look at two different options and find out what their unique advantages are. Polypro is popular due to its chemical wear resistance, weldability, and electrical resistance. It has a variety of uses, most notably packaging applications, consumer goods, and medical equipment. A big challenge for engineers is to create functional prototypes that will closely mimic the real-world part. Before 3D printing, Polypro prototypes could only be produced through molding, which would delay the time to market. In the early stages of product development, you can get away with using a material such as ABS, but when executing a field test it is necessary to test in the same material as your commercial production part. The first material we will cover is Ultimaker Caverna Polypro. It is made by melt processing two polymers at near-equal parts, to create a filament with a co-continuous morphology. This means there is a consistent distribution of interconnected channels. After dissolution, the water-soluble phase leaves behind a cave-like network of interconnected channels making it light, soft, [...]

What Will Manufacturing Look Like in 40 Years?

Manufacturing 40 Years ago Back in the late 70’s, I started my career at Grumman Aerospace and we had all NC (Numerical Control) machines in our plants as well as the very first licenses of Catia ever used in the U.S. ‘CNC’ (Computerized Numerical Control) technology was extremely new and had not yet made its way to our plant. Our machines to manufacture parts had no memory and were driven by mylar or paper tapes that had G-Code programs punched into them. Longer programs simply were made up of longer tapes. The NC machine read the tape and simultaneously ran the program. If the tape tore, a new one was punched. NC machines were extremely expensive and well out of reach for most small to mid-sized job shops and manufacturers. There was no ability to edit programs at the controller and no ability to store multiple programs on a controller. If there was an error in the program, it meant scrapping the tape (and possibly the part) and starting all over. Programmers of NC machines were referred to as ‘NC Programmers’ and likewise, we also had ‘NC Operators’. In the early 1980s, CNC machines began showing up at Grumman. The need to punch [...]

Desktop Metal Launches 316L Stainless Steel

Shop System Binder Jetting Enables Cost-Effective Batch Production of High-Quality 316L Stainless Steel Parts Via Additive Manufacturing Desktop Metal recently announced it has qualified the use of 316L stainless steel for the Shop System™, the world’s first metal binder jetting system designed for machine shops. With an expanded materials portfolio, users can now leverage affordable, high-quality binder jetting technology to print end-use parts in 316L stainless steel with throughput, print quality, and productivity unattainable via legacy additive manufacturing processes. Known for its corrosion resistance, high ductility, and excellent mechanical properties at extreme temperatures, 316L is an austenitic stainless steel well-suited for demanding environments and applications, such as parts exposed to marine, pharmaceutical, or petrochemical processing, food preparation equipment, medical devices, surgical tooling, and consumer products such as jewelry. “The launch of 316L for the Shop System is a part of an aggressive and extensive materials roadmap to broaden our AM 2.0 portfolio and address a rapidly expanding set of use cases for our print platforms,” said Jonah Myerberg, co-founder and CTO of Desktop Metal. “We are fully focused on developing opportunities for our customers to produce parts competitively with conventional manufacturing, and we are excited to be able to extend our binder jetting [...]