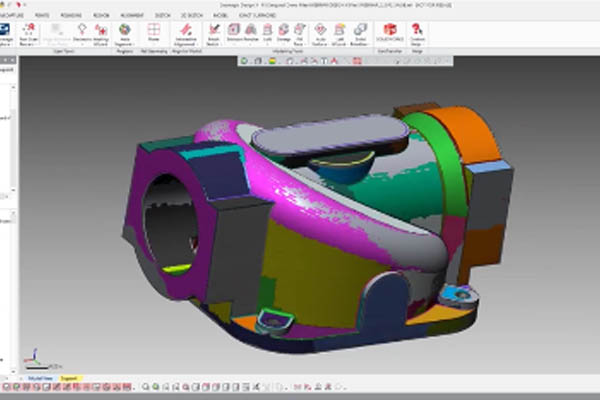

Geomagic Design X Reverse Engineering Features

This blog post will compare two modeling tools in Geomagic Design X, the Sweep and Pipe Wizards. Modeling wizards are intelligent tools used to extract 2 or 3-dimensional sketches, profiles, and features, from 3D scan data. They help users perform tasks in an automated fashion, tasks that would otherwise be very complicated to perform manually. Let’s take a look at the Sweep wizard. This tool quickly extracts sweep objects from a mesh. It intelligently computes sectional profiles and the path based on the selected regions. In this example, we have a compound curve elbow. We can auto segment the scan to identify all of the features. We can also analyze it with Sweep Wizard. By selecting the surface, the computer opens up two different viewpoints where we can analyze the geometry. We click OK and hide the scan model, so we can see the generated surface. As we can see, the generated surface is very accurate to the original scan. The main goal was to capture the path shown below, a compound curve. This would be very difficult to extract through manual measurement, and the result would not be as accurate. Next, we will analyze the same feature with Pipe Wizard. We repeat [...]

RIZE Debuts Rizium Glass Fiber Filament for Full-Color 3D Printing

reprint from https://3dprintingindustry.com/ 3D printer manufacturer RIZE has debuted its new highly-durable RIZIUM Glass Fiber filament for use with its 3D printers. The composite material claims to have high dimensional stability and high stiffness and is primarily intended for large-part production. RIZIUM Glass Fiber is also RIZE’s only composite material to date that is suitable for full-color parts produced on the company’s xRize 3D printer. Ronnie Sherrer, an Application Engineer at 3D printing service provider Azoth, states: “We like the print reliability that RIZIUM Glass Fiber delivers to the RIZE product line. Azoth can be confident in the quality and strength of RIZIUM GF parts. Being able to transform 3D rendered models into accurate full-color parts is something our customers love.” Functional gearbox front 3D printed with RIZIUM Glass Fiber. Photo via RIZE. Large-format full-color 3D printing RIZIUM Glass Fiber is compatible with every 3D printer in RIZE’s current portfolio. The composite is based on the company’s unique cyclic olefin-based matrix, which reportedly does not release harmful emissions at typical extrusion temperatures. It also features extremely low moisture absorption characteristics and has excellent chemical resistance. The filament leverages RIZE’s Augmented Polymer Deposition technology, whereby filaments are able to combine with [...]

Verisurf for Metrology

Using a Portable Arm for Part Inspection This blog post will introduce you to using a portable, 6-axis arm and powerful metrology software for part inspection. The software that we will be referring to is Verisurf and the 6-axis arm metrology software for part inspection is Master 3D Gage. Read on to learn how these tools are used. The Master 3D Gage is a 4-foot arm capable of measuring from very small to fairly sizeable parts using either a probe tip or scanning device. In this article, we will focus on probe-based inspection. Verisurf software runs ‘inside’ of Mastercam, the most popular and widely used CAM software in the world. This enables both CNC part programmers and part inspectors to use the exact same User Interface to program as well as inspect parts. While this article explains Verisurf running the Master 3D Gage, the software could also be used to program manual and automated CMM’s, trackers, and even laser projectors. In fact, there are dozens of metrology devices that may be driven by Verisurf metrology software. The first part of any inspection involves an alignment process. In this example, we placed six virtual targets onto the model to then be used for part [...]

Formlabs Introducing Factory Solutions: Webinar on Demand

Introducing Factory Solutions: How to Build Additive Factories for High Value Manufacturing Projects https://cimquesttv.wistia.com/medias/42qmn7mbjw?embedType=async&videoFoam=true&videoWidth=640 Find out more about Formlabs products here.

Formlabs Introducing Factory Solutions: How to Build Additive Factories for High-Value Manufacturing Projects

Formlabs Introducing Factory Solutions - Webinars on Demand: How to Build Additive Factories for High-Value Manufacturing Projects The global conversation about additive manufacturing in production is full of misconceptions and confusing hype. We’re launching Formlabs Factory Solutions to help you cut through the hype and build high-value additive manufacturing projects at scale. The agile digital factory, built around 3D printing, provides unprecedented opportunities for decreasing costs and increasing revenue. We’ve created Factory Solutions to make it easy for you to turn these opportunities into immediate wins for your business. In this briefing, Formlabs’ Global Business Development Lead Dan Recht will show you how to identify, assess, and benefit from opportunities to use additive manufacturing as a production technology. What you will learn: Five ways in which additive manufacturing creates value when you adopt it at scale. Our Factory Solutions team’s method for evaluating the costs and revenue opportunities of additive manufacturing projects. How you can turn additive manufacturing into an unfair advantage for your business using the three components of Factory Solutions.

HARBEC Utilizes XYZPrinting for Robotic Applications

HARBEC is a manufacturing contractor which, for over 40 years, has aimed to provide effective solutions to customer problems and requests. HARBEC provides tight tolerance prototypes, tooling, machined components and injection molded parts, while keeping sustainability in mind and having a social conscience. HARBEC has been known to not only suffice requirements with their projects, but to exceed expectations, using cutting-edge technology to proficiently accomplish their objectives. CHALLENGE HARBEC utilizes robots to perform some of the tasks which are part of the daily manufacturing processes at the facility. A robot requires fitted tools to complete the duty for which it is called upon. These tools are called end of arm tools, which in many cases are multiple pneumatically actioned claws or grippers, attached to a bracket of the required shape. HARBEC owns many different 3D printing technologies which would be useful in creating the brackets for each job. Initially, a SLA printer was used to create the bracket. This bracket had decent mechanical properties, and worked well for the job at hand. Interest was shown to reduce the weight of the gripper brackets that are to be utilized by the robots. Using SOLIDWORKS topology optimization technologies, a new design was created which reduced [...]