What PMI means to the future of integrated CAD/CAM

Since the mid-1980s, when PC based CAD/CAM started its explosion due to the advent of 386 computing technology, our industry has had an ongoing hurdle to overcome . . . How to convey manufacturing and inspection information with the original model design. Historically a manufacturer would provide a job shop with a CAD model and an inspection drawing, increasing the likelihood for inspection drawing interpretation error. Wouldn’t it be ideal if the manufacturing and inspection data could all remain with the model throughout all post-design functions? Looks like PMI (Product Manufacturing Information) has us finally following a path that will enable this groundbreaking technology to become a reality. Being able to seamlessly connect all manufacturing and inspection data to CAD models, including dimensions with tolerances, GD&T, datums, notes, labels and any other pertinent information modern-day CAD product users can seamlessly convey this information to downstream applications. This helps to greatly minimize the likelihood of error while reusing the PMI data for CAM systems to automatically select optimal toolpath parameters. Additionally, FEA and inspection products can also ‘share’ this data for their respective disciplines, again promoting the reuse of original PMI CAD data for ALL downstream applications. While many CAD, CAM, and FEA products [...]

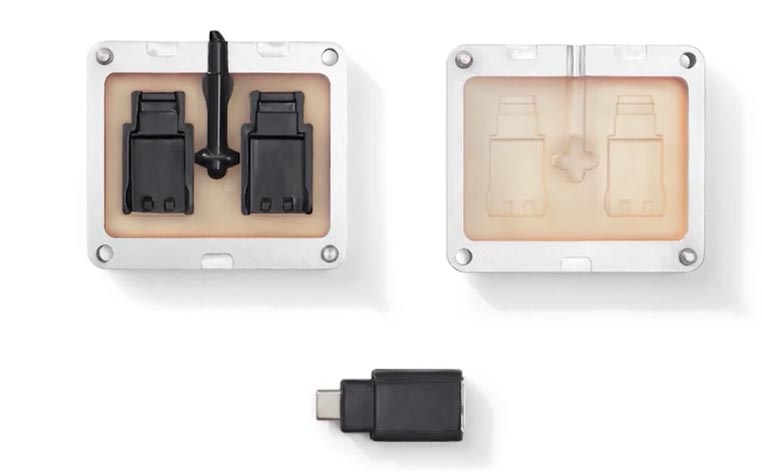

Mold Making with Formlabs 3D Printers

This post will explore 3D printing for mold making using Formlabs 3D printers. Mold making with desktop 3D printing allows engineers to expand their prototyping toolkit. It opens up a world of production materials, offering the ability to make short-run batches and to test designs before larger-scale production. Three types of molding strategies can be applied with Formlabs. These include injection molding, thermoforming, and casting elastomers. The Form 3 can print inexpensive injection molds to validate and improve designs before metal tooling. They can be printed at both 100 microns for speed or 50 microns for high detail and smoothness. In this example, the newer High Temp resin was used to print an enclosure for a USB device. High temp resin eliminates the thermal shock or deformation found with lower temp materials. The beauty of this example is that the team was able to create three iterations, helping them to remove sink marks, air taps, and correct part shrinkage. Thermoforming is common for packaging, orthodontic retainers, and food-safe molds. The dies experience less pressure than injection molds, but High Temp is still the best choice. Standard resins can still be used for lower temperature plastics like vinyl. In this case study, a thin [...]

Metrology Minute – How Do I Choose My First Scanner? – Part 1

Considering part sizes Notice that the title says first scanner. More than likely, companies who invest in non-contact inspection, scan-based reverse engineering or need to perhaps scan and 3D print objects will own multiple scanners in the course of a career. However, some scanners have the ability to swap out lenses, projectors and the like and can change a scanner’s capabilities by swapping hardware. Just like CNC machinery or 3D Printers, scanners can vary greatly regarding speed, accuracy, resolution, repeatability, part sizes (Field-of-View), price, ongoing warranty, post-sales service and support, and so on. So perhaps one of the first realizations to accept is that there isn’t a ‘One-Size-Fits-All’ scanner. This three-part Metrology Minute will go through what you should consider when choosing the best, first scanner for your company. Whether the scanner is based on laser or structured light you will want to review scanners that can handle the bulk of your scanning requirements because solving them all using a single scanning device may not be possible. As a general rule of thumb, scanners designed to scan tiny objects offer higher accuracy and resolution capabilities, whereas scanners designed to scan a plant or exterior of a building generally are far less accurate with [...]

Formlabs Launches New Materials

One of the most powerful advantages of stereolithography (SLA) 3D printing is the wide range of printing materials and Formlabs recently announced six new materials across the Form 3, Form 3B, and Form 2 SLA 3D printers. These new resins continue to challenge what's possible with 3D printing by further expanding use cases and design possibilities with our existing printers. Our latest resins support a wide range of industries and use cases within these industries, ranging from healthcare to manufacturing. The new material families and resins address the following segments: Engineering, Product Design, and Manufacturing: We are introducing a new family of Flexible and Elastic Resins consisting of Flexible 80A Resin, a reformulation of our current Flexible Resin, and Elastic 50A Resin. Healthcare: Our new line of BioMed Resins that includes BioMed Clear Resin and BioMed Amber Resin brings biocompatible resins to healthcare professionals across the globe. Dental: As part of our Materials Partnership Platform with BEGO, we’ve introduced a novel material for temporary restorations. We are also introducing a new resin for manufacturing custom impression trays, as well as improving our long-term clear material indicated for splints and occlusal guards. These two resins were developed at our in-house ISO 13485 facility. Flexible [...]

HP 3D Material Spotlight: Polypropylene

HP 3D Material Spotlight: Polypropylene Watch this on demand video of how HP is opening up more possibilities for manufacturers with the use of polypropylene. https://cimquesttv.wistia.com/medias/799rm07dca?embedType=async&videoFoam=true&videoWidth=640

Mastercam 2021-Update Rollout Meeting Webinar

Mastercam 2021-Update Rollout Meeting Webinar Cimquest held 5 online Mastercam 2021-Update Rollout Meeting Webinars since the release of Mastercam 2021. View the webinar on demand here, along with the combined Q&A sessions. https://cimquesttv.wistia.com/medias/6uzlvhodo7?embedType=async&videoFoam=true&videoWidth=640