Deep Dive into HP Jet Fusion 500/300 Series 3D Printers

The HP Jet Fusion 500/300 Series 3D Printers enable the production of functional parts in color, black or white without compromising mechanical properties. These printers are ideal for focused teams who want to work smarter and prototype faster. Watch the video below to discover how the HP Jet Fusion 500/300 Series 3D Printers work. For more information on the HP line of 3D printers, please click the button below. Button Text

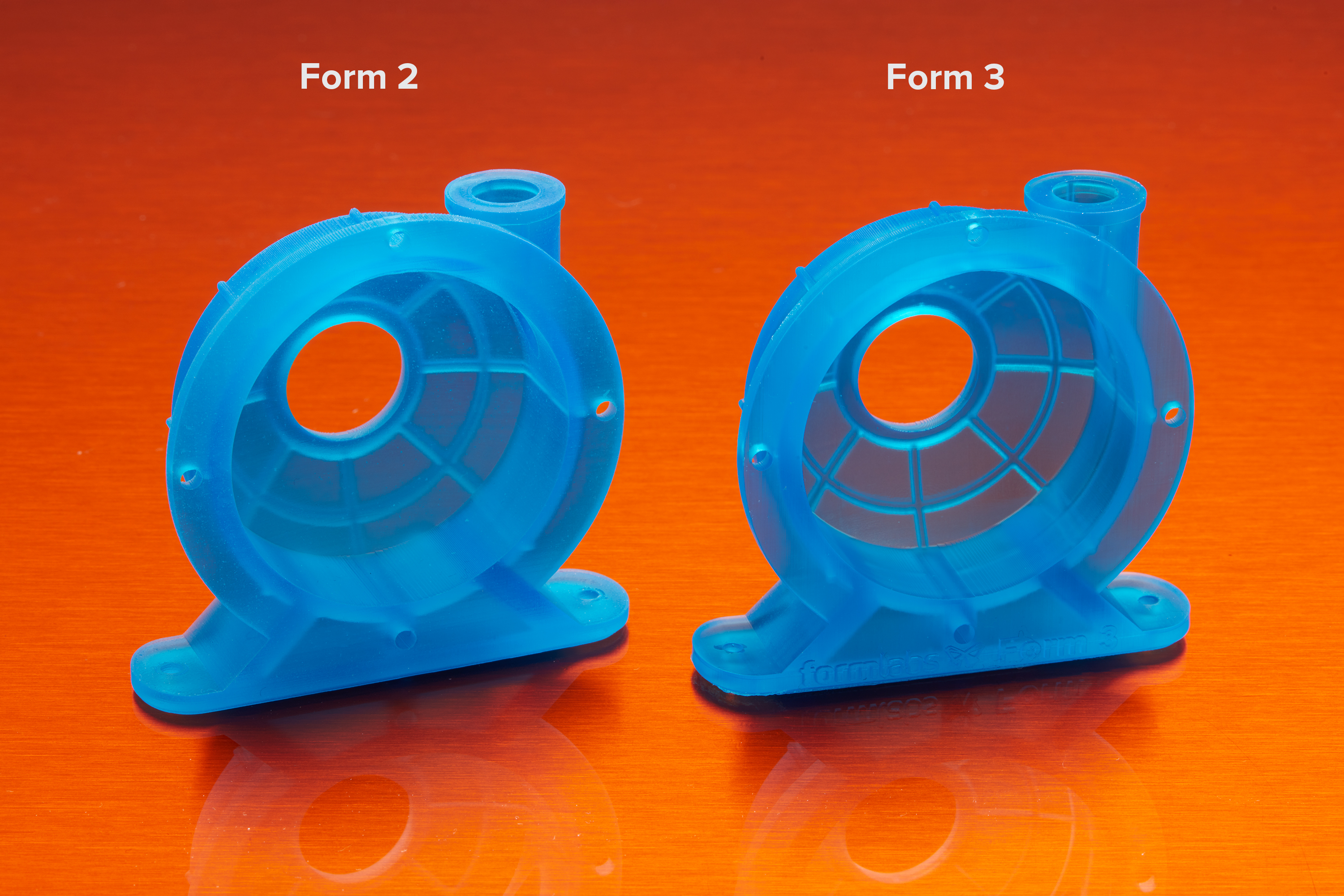

Form 3 Part Clarity and Surface Finish

The new Form 3 3D printer from Formlabs represents the next generation of industrial 3D Printing. With advanced Low Force Stereolithography (LFS)™ technology, Formlabs has completely re-engineered resin-based 3D printing to drastically reduce the forces of the print process. One of the benefits of Low Force Stereolithography (LFS) is that the flexible tank significantly reduces stress on the part during the peel process. This results in much clearer parts with improved surface finish as shown in these comparison photos of a Form 2 and Form 3 print. See for yourself by viewing the images below. Learn more about the Form 3 and Form 3L in the video below. For more details on this new printer, please click the button below. More Info

XRIZE Wins Innovation Award

New Equipment Digest has just announced XRIZE as one of their six 2019 Innovation Award Winners. XRIZE was the only 3D printer to receive this distinction. The NED staff selected finalists from approximately 2,000 new products, solutions, tools, and technologies to identify the top 22 new products that fit their “game-changing” criteria for the award. Read votes then decided the six winners. “The 2019 class of NED Innovation Award winners redefine their markets for a smarter, more efficient manufacturing world.” XRIZE One of the best things about the XRIZE, the world’s first, true color desktop industrial 3D printer, is that it's as easy and safe to use as a regular 2D printer. With this, users can manufacture functional polymer and composite parts in full color due to the patented Augmented Deposition process that extrudes an engineering-grade thermoplastic and simultaneously jets cyan, magenta, yellow, and black. And because RIZE’s intelligent and innovative solutions focus on the user as much as the machine, XRIZE enables marking to provide much-desired IP security, traceability, and branding. For more information about the Rize line of 3D printers, please click the button below. More Info

Digital Manufacturing Accelerates a Sustainable Industrial Revolution

reprinted from www.weforum.org Ride into the future … 3D printing millions of industrial parts more efficiently and sustainably than ever before. The Fourth Industrial Revolution is shaping up to be one of the most significant opportunities of our lifetime. We are already seeing jobs, policies, industries and entire economies shifting as our digital and physical worlds merge. This represents an important opportunity for business and for society. With this industrial revolution, we have a collective responsibility to ensure sustainability is a priority from the start. According to the World Economic Forum, the value of digital transformations in the Fourth Industrial Revolution is estimated at $100 trillion in the next 10 years alone, across all sectors, industries and geographies. The manufacturing sector, which has long been a driver of global prosperity and economic growth, is key to this transformation. Emerging technologies such as AI, robotics and 3D printing are disrupting the manufacturing industry and unlocking new ideas and potential that were previously unimaginable. With this change comes opportunity. 3D printing, in particular, is at the forefront, given its ability to reshape the sector. If we make the right decisions, it can also drive a sustainable impact for our planet, people and communities. [...]

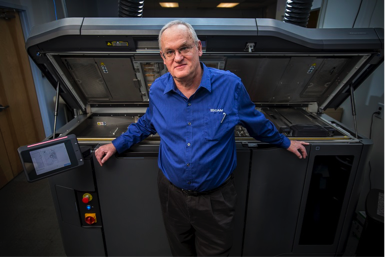

Multi-jet Fusion Technology Sparks 3D Printing Revolution

Doug Campbell, vice president of SICAM, with his company’s multi-jet fusion machine. Reprint from NJBIZ.com Hillsborough-based SICAM Corp. specializes in 3D printing, prototyping, tooling, and manufacturing. Incorporated in 1990, SICAM has clients in 38 states from a variety of industries: aerospace, automotive, computer, consumer, government, industrial, medical, pharmaceutical and telecommunications. The company also now owns a multi-jet fusion machine that vice president Doug Campbell says will make 3D printing technology a more viable option than previous technologies. Campbell said SICAM is using the machine, which it purchased for $400,000 from HP Inc., to change manufacturing. He predicts the multi-jet fusion machine will revolutionize 3D printing — or additive manufacturing — for production. Until the 3D printing equipment became cost-effective, there was no point in designing for additive manufacturing, Campbell said. Multi-jet fusion is a powder-based technology that does not use lasers and produces strong, lightweight products. The technology is better than other 3D processes including injection molding because it is faster and less expensive, Campbell explained. “The advantage of designing for additive manufacturing, what is going to change in manufacturing, is the concept of now you can design with more freedoms,” Campbell said. “A good example is Volkswagen who makes an [...]

HP 3D Printing for Shoe Insoles

Today we are going to take a look at a company using 3D printing to manufacture customized orthotic devices. iOrthotics makes custom insoles for podiatrists around the world. Their goal is to create a better, more scalable solution for their clients through digital manufacturing. Traditionally, iOrthotics' method for creating an insole required a mold. This involved casting the patient's foot in plaster. This could be uncomfortable for the patient and would often lead to inaccurate measurements as the casts were taken in a non-weight-bearing position. Once a mold was complete, orthotics were made through traditional methods that required skilled labor and finishing. These methods often needed multiple fittings to achieve a satisfactory result. But perhaps the biggest downside was the waste from these processes. In order to keep up with increasing demand and to develop a competitive advantage, iOrthotics formulated a digital workflow by adopting 3D scanning and the HP Jet Fusion 4200. The first step was to enable 3D scanning thereby eliminating the need for a mold. Advancements in 3D scanning enabled more exact measurements and the foot could be measured in a more organic position. With the CAD file ready, iOrthotics could then use their Jet Fusion 4200 to print the [...]