Lubrizol Introduces First 3D Printing Materials

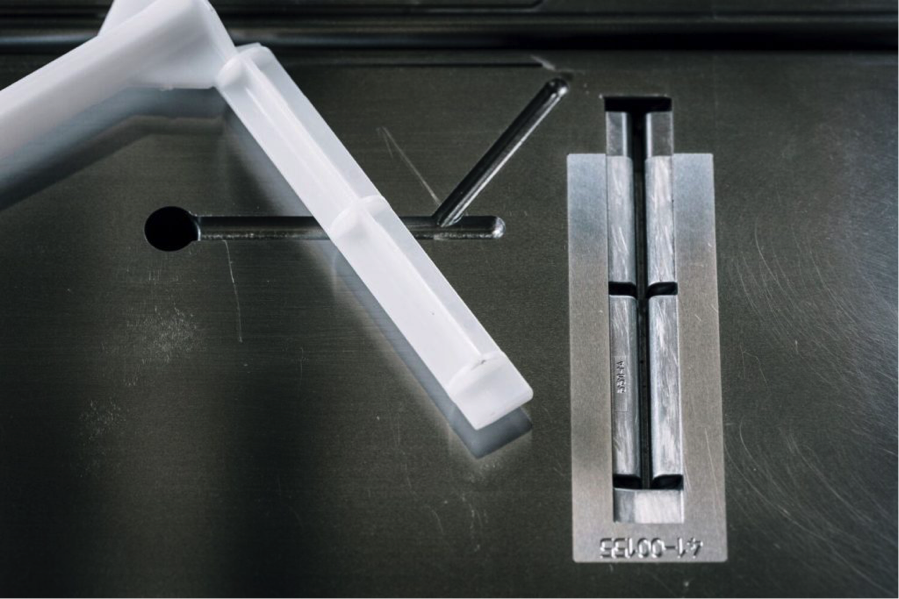

(Reprint from https://www.tctmagazine.com) Parts manufactured in TPU with the Multi Jet Fusion process. Lubrizol, a specialty chemicals company, has introduced its first three 3D printing material products after its entry into the additive market. The Ohio-based company has followed the likes of BASF, SABIC, and Clariant into the industry to offer its expertise, particularly in the development of thermoplastic polyurethane (TPU) materials, to those pushing AM from a prototyping tool to a volume [...]