Welcome to the Cimquest Blog!

Check here often to find Cimquest, Mastercam and 3D Printing happenings, product offerings and update info along with general Industry trends and breaking news.

June 2017

Geomagic Design X

With Geomagic Design X software you can easily produce a fully featured, editable, native CAD model, directly from a scan.

What is Design X? Design X software is a tool that enables you to recognize geometrical features on a scan, utilize them to create CAD features, then transfer that tree of features directly out to the feature tree of your CAD system. Let’s break this process up into three stages: Auto Segment, Feature Extraction, & LiveTransfer […]

CPI Aerostructures Uses FDM 3D Printing for Custom Tooling

Reprint from www.additivemanufacturing

Adding an FDM 3D printer enabled a producer of subassemblies for aircraft to bypass traditional tooling solutions on many custom tools and bring much of this work in-house. Cimquest customer, CPI Aerostructures was in a good position in 2013. After years as a small business providing subassemblies almost exclusively for military aircraft, the company was experiencing a massive growth spurt. Sparked by an influx of both commercial and military work, the company had […]

May 2017

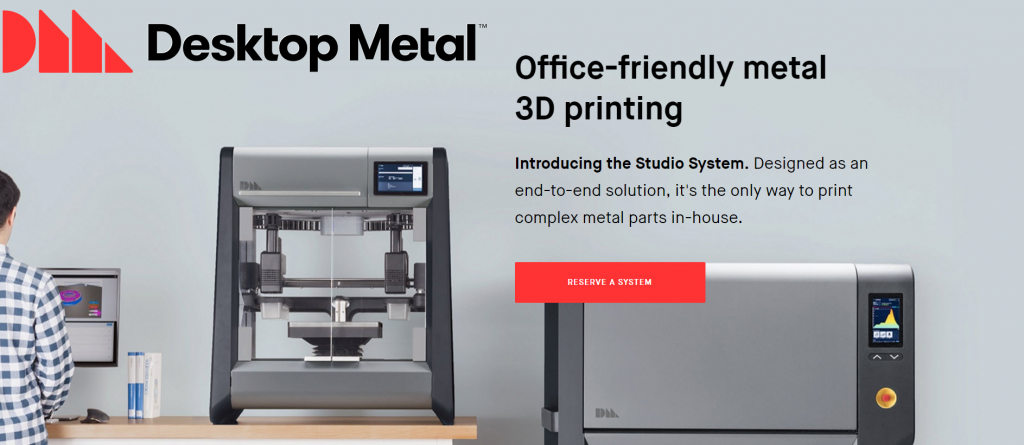

Cimquest Now Selling Desktop Metal 3D Printing Systems

Cimquest is excited to announce that we are now contracted to sell Desktop Metal. This means that in addition to offering, Mastercam, 3D scanning and inspection, as well as traditional 3D printers, we can now offer the New England and Mid-Atlantic territories a Metal 3D Printer at a price point that will allow the manufacturing community to venture into the exciting field of 3D Metal Printing.

This […]

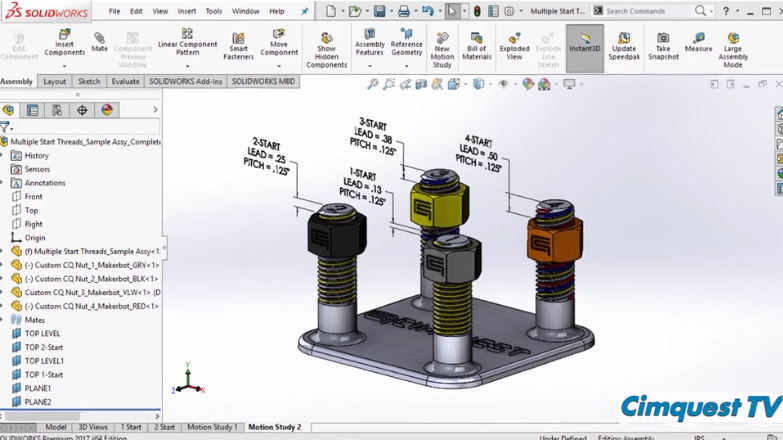

SolidWorks 2017 Multiple Start Threads

Today we are going to talk about the enhanced functionality to the Thread feature in SolidWorks 2017, mainly using multiple start threads. There are various reasons why someone might use threads with multiple starts. The main one is that it allows the lead distance of a thread to be increased, without changing its pitch. This proves useful when fine threads are required, but […]

Employee Spotlight – Russell Jennison

1. What are your responsibilities at Cimquest?

Post processors are the link between Mastercam and individual machining centers. I customize these to maximize customer productivity and make sure every machine a customer wants to utilize talks […]

Introduction to 3D Metal Printing with Desktop Metal

Join Cimquest and Desktop Metal on Friday, May 19th at 9 AM for an informative webinar on 3D Metal printing, a new and affordable addition to the 3D metal printing industry. This new technology promises to be a game changer in the way products are brought to market in the future. You don’t want to miss this opportunity to learn more about it.

In this webinar Ben Arnold […]