Welcome to the Cimquest Blog!

Check here often to find Cimquest, Mastercam and 3D Printing happenings, product offerings and update info along with general Industry trends and breaking news.

April 2023

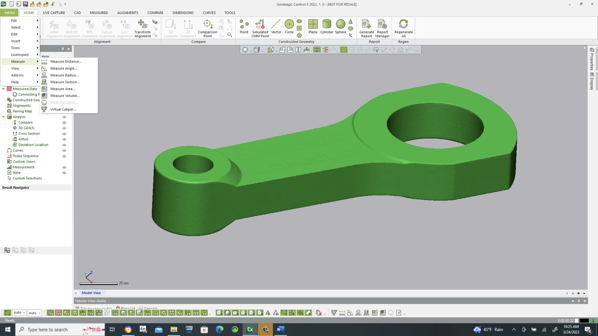

Metrology Minute – Control X Measure Menu

While most users of Control X are interested in producing color maps, whisker plots, dimension checks, and GD&T analysis of the scan as compared to the nominal CAD model, it is important to note that there are several “mesh-only” functions for measuring a scan model that do not require a nominal CAD model.

The Measure Distance menu simply measures the distance between two […]

March 2023

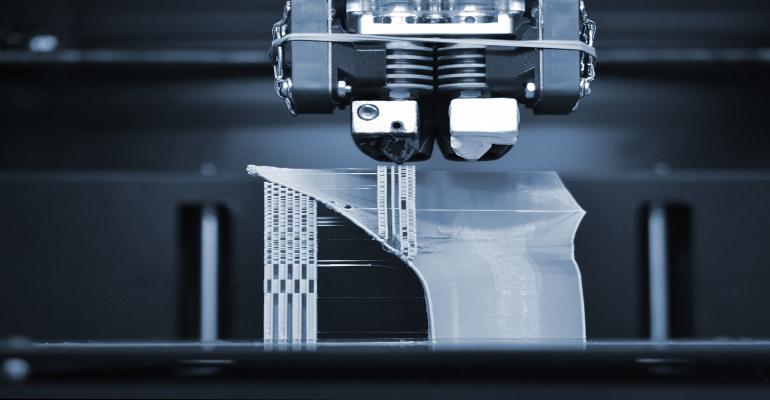

3D Printing Surged 23% Last Year

3D Printing has surged 23% in 2022 and is now a $13.5 billion industry.

(A reprint from DesignNews)

Photo courtesy of Design News.

Photo courtesy of Design News.

The fourth quarter of 2022 capped a strong year for additive manufacturing markets, according to SmarTech Analysis. Even in the face of uncertain economic conditions, the growth rate for all 3D printing hardware, materials, software, and services expand by 23% in […]

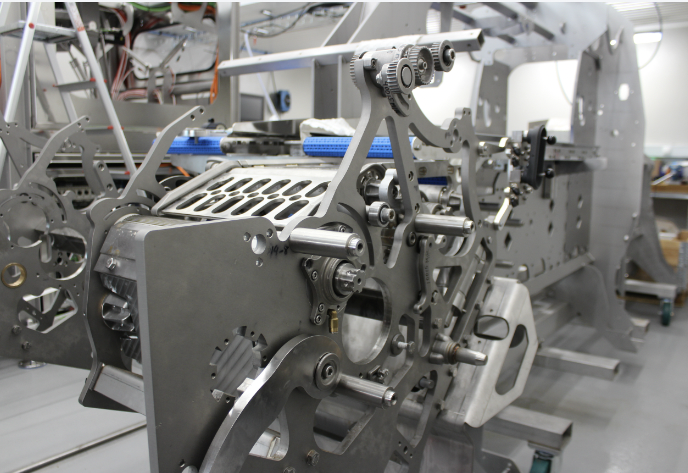

Metal 3D Printing is Spicing Up Food & Beverage Equipment

Desktop Metal has compiled the top 5 reasons we see the food and beverage industry moving to metal 3D printing. While mentions of 3D printing for food may bring to mind chocolate extruded into cool decorative shapes, additive manufacturing is actually transforming the industry behind the scenes – making food and beverage processing equipment safer, more productive, and delivering all-new innovations to the nearly $60 […]

Learn How to Leverage Reverse Engineering, Inspection and 3D Printing

Come join Penn State DuBois and Cimquest for an event on how to leverage Reverse Engineering, Inspection, and 3D Printing solutions!

Date: Thu, April 6, 2023, 9:00 AM – 3:00 PM EDT

Location: DEF Room 202 1 College Place DEF Room 202/204 DuBois, PA 15801

During this event, you will have the option to come and go as you please. There will be an opportunity to network, […]

A Tribute to Mike Sljaka

The Cimquest family woke up on Monday, Mar 13, 2023, to the news that our beloved colleague and friend, Michael Sljaka, had succumbed to his longtime battle with cancer on Saturday, March 11th.

The Cimquest family woke up on Monday, Mar 13, 2023, to the news that our beloved colleague and friend, Michael Sljaka, had succumbed to his longtime battle with cancer on Saturday, March 11th.

Mike worked for Cimquest as a Senior Applications Engineer since the acquisition of Services Four Automation in October of 2011 where he worked since August 2007. Mike quickly became popular with customers and his […]

Cimquest Adds Meltio to Their 3D Printing Lineup

Cimquest Becomes Meltio’s Official Sales Partner

Cimquest is going to play a key role in the distribution and support of the Meltio metal 3D printing solutions in the North Eastern United States market, as an official sales partner. Meltio offers a pioneering metal 3D printing solution that enables industrial applications with a process built around welding wire, the safest, cleanest, and most affordable metal feedstock in the […]

Cimquest is going to play a key role in the distribution and support of the Meltio metal 3D printing solutions in the North Eastern United States market, as an official sales partner. Meltio offers a pioneering metal 3D printing solution that enables industrial applications with a process built around welding wire, the safest, cleanest, and most affordable metal feedstock in the […]