Metrology Minute – Interpreting 3D and 2D Color Maps

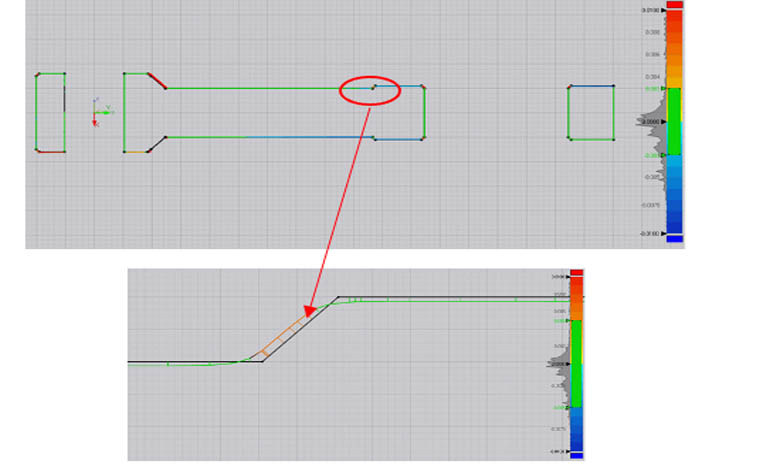

Let’s take a look at how to interpret 3D and 2D color maps using inspection software. Non-contact inspection software that is designed to show color maps will align the scan of a manufactured part with a nominal CAD model and actual manufacturing tolerances are revealed in a clear, easy to interpret fashion. Some products can show a blended color map whereby a color (typically green) represents a nominal tolerance. For the connecting arm color map [...]