Let’s take a look at the new Desktop Metal Fiber 3D printing system. The Fiber system brings continuous fiber 3D printing to the desktop of engineers and designers. Composites are commonly used in performance automotive, aerospace, and many other industries (consumer goods, and machine design). Composites are great for parts that require the strength and stiffness of metal but at a fraction of the weight.

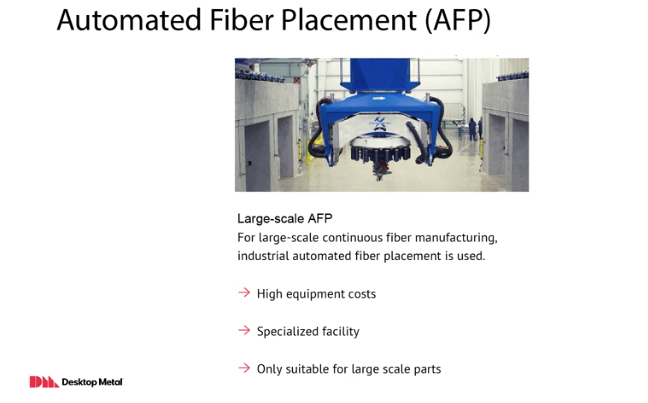

Traditional Automated Fiber Placement (AFP) processes are only suitable for large scale parts and require million-dollar systems. And while manual methods do exist, these can be labor-intensive with expensive tooling.

Desktop Metal was able to scale down AFP and make it accessible via 3D Printing. They did this through a new process called micro automated fiber placement.

During the μAFP process, one Fiber™ printhead deposits a continuous fiber tape along critical load paths to build dense reinforced sections while a second printhead extrudes chopped fiber filament to build a high-resolution exterior shell. The materials used to make the resulting parts are two times stronger than steel at one-fifth the weight (up to 2,500 MPa tensile strength and <1.5 g/cc).

Through this unique process, users can print parts with properties comparable to metal, with some properties even exceeding those of metal. Four materials have been developed for this system.

PEKK reinforced with Carbon Fiber, parts are durable and well-suited for extreme environments including high-temperature applications.

PEEK + Carbon Fiber results in composites that are strong and stiff, making it great for high-wear jigs and fixtures.

The Nylon 6 (PA6 is suitable for operations where ESD compliance is required.

And finally Nylon 6 (PA6)+ Fiberglass match for sporting goods or marine applications, parts in exposed environments with potential for corrosion.

The Fiber will be available as a subscription plan with two different options. The Fiber LT is outfitted with one material Nylon 6, while the Fiber HT will have access to three materials. The Fiber HT also offers greater control for more advanced users, with the ability to have user-defined fiber paths.

As you can see, the Fiber system grants engineers access to industrial-grade composites, at the comfort of their desktops. For more information on the Desktop Metal Fiber system please click the button below.

Leave A Comment