About manufacturing tooling

Tooling is a general term for components used in various manufacturing processes—including machining, injection molding, extrusion, stamping, casting, as well as workholding jigs, fixtures, and end of arm tooling. A single tooling mechanism may consist of several complex parts or one unique part. Tooling is used widely across all manufacturing processes. Though often created in-house by manufacturers, tooling may be outsourced to a specialty tooling shop when complexity or lead time exceeds in-house capabilities.

The Challenge

When a manufacturer gets a drawing or CAD model for a new product, the first thing that must be done is plan how the part will be manufactured—this plan almost always requires creating tooling. For traditional manufacturing methods, tooling fabrication demands significant non-recurring time, cost, and effort. Both to design the tooling, and then to manufacture it.

Once tooling is created and volume production begins, manufacturing lines still need to be maintained, and may often need replacement parts as components wear out or break. To avoid downtime, those maintenance, repair, and operations (MRO) parts need to either be warehoused for immediate use or produced very quickly to get the manufacturing line back up and running as quickly as possible.

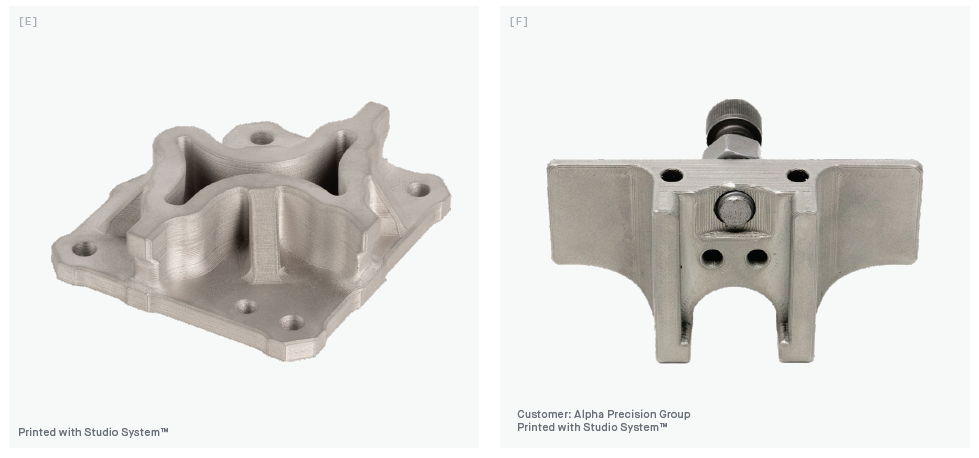

Many forms of tooling require materials with excellent hardness, wear, resistance to thermal cycling, and lifetime. While tool steels possess those properties, they can be very difficult to manufacture. Their high hardness makes machining them expensive and time-consuming due to the slow cutting rates and high tool wear.

The Solution

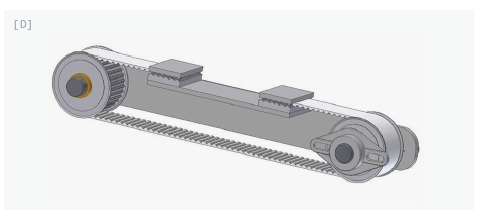

Additive manufacturing dramatically simplifies the process of creating tooling and fixturing. With no dedicated operator needed to monitor 3D printing systems, manufacturers can simply upload their designs to the printer, and finished tooling will be ready to use in days, making it faster to stand up manufacturing lines.

For maintenance, repair and operation (MRO) components, additive manufacturing’s speed and flexibility allow for on-demand tooling and enabling users to print parts when and where they’re needed, simplifying production and reducing part cost and lead time.

Printing parts also makes it easier to create tooling from difficult-to-machine materials like tool steel. Since 3D printed parts are not machined from a single block of metal, but created layer by layer, near net-shape parts can be created without waste. If needed, critical dimensions can then be machined; reducing tool wear and manufacturing lead time.

Printed tooling also enables new, higher-performance designs which could not be created or justified with traditional manufacturing. Light weighting features – which would normally add significant cost – can easily be fabricated via infill or cutouts. Those features reduce part costs and processing time – less material equals faster prints and less material costs.

Additive manufacturing also makes it easy to include conformal cooling channels that snake through parts like mold cores and cavities, leading to reductions in cooling time and increased mold throughput.

For more information on the Desktop Metal line of 3D printers, please click the button below.

Leave A Comment