Autodesk Netfabb Lattice Assistant and Lattice Commander

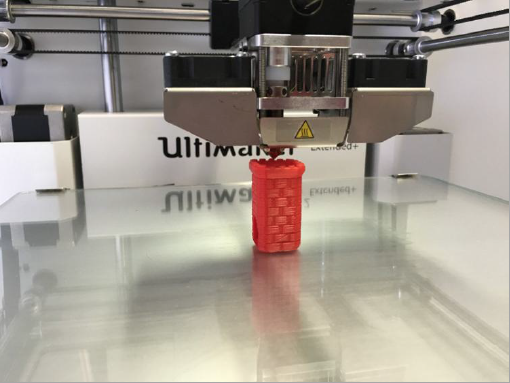

Today we are going to cover how to use Autodesk Netfabb to create lattices with two of Netfabb’s internal tools, Lattice Assistant and Lattice Commander. Autodesk Netfabb is Additive Manufacturing software that allows you to repair, prepare and build your parts. Lattice Assistant and Lattice Commander are currently available as tech previews, and included in Netfabb Premium and Ultimate. The first tool we will discuss is Lattice Assistant, which combines hollowing, lattice generation and merging with tools to generate perforation and the matching plugs for drainage of unused material. Shown below is a connecting rod used for one of our Mastercam events. It is fairly thick, and you can see the various options from the thickness of the skin to size and shape of the lattice cells in the dialogue box on the left. In this example, we selected a simple X cell and hit calculate. With the part hollowed and latticed, we have to add perforations in order to be able to remove the unfused powder which can be reused in the HP JF 4200. The second tool for latticing is Lattice Commander, which can be used to create and modify the individual lattices and wall sections, or skins, for a project. With this [...]

Startup Businesses Can Claim Cash Rebates

We want to share this information because the window is soon closing on the opportunity to get up to $250,000 in cash rebates for startups purchasing new equipment. This equipment includes 3D printing equipment, materials, and service providers. The following article was written by Charles Goulding & Raymond Kumar of www.rdtaxsavers.com. 3D printing is poised to become an integral component of production in a variety of industries, ranging from traditional manufacturing and food processing to laboratories and architectural design. Reasons for integrating 3D printing include cost-reduction, increased efficiencies, and better methods for prototyping. Startups not only developing 3D printers but also utilizing the technology in operations have a unique opportunity to claim up to $250,000 annual in cash rebates as part of the Federal R&D Tax Credit program. To timely monetize the payroll tax credit, startups must file their 2018 income tax returns by the end of Q1 2019. The Research & Development Tax Credit Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria: Must be technological in nature Must be a component [...]

RIZE’s Hybrid AM Helps Solve Complex Warfighter Problems

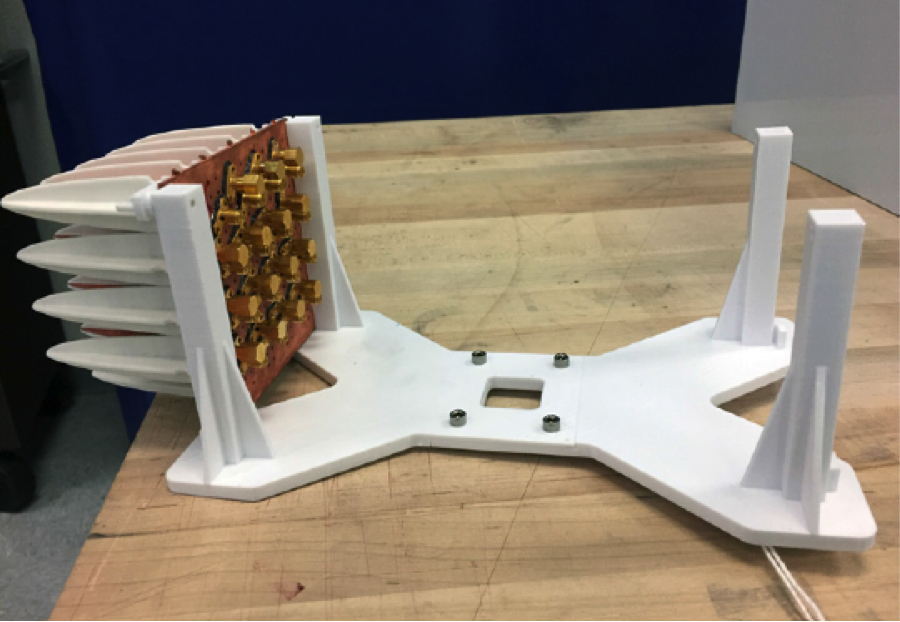

SI2 Technologies, Inc. produces functional parts for the Department of Defense with their RIZE ONE 3D printer up to 6X faster and at a cost savings of $2K per part. They wanted one machine that could combine 3D printing and inkjet printing capabilities. SI2’s core mission is to ‘make things smart’ by pushing the boundaries of where antennas can be placed and how they can be made. SI2’s mission requires the latest technology and innovation in the additive manufacturing field to deliver an advantage to the warfighter. Much of the development work that SI2 does happens in their state-of-the-art facility. Among their collection of modern equipment, SI2 has 3D printers ranging from entry-level consumer 3D printers to much more expensive and complex wide-format inkjet equipment. Although SI2 had a range of 3D printers and wide format inkjet printers, they didn’t have a single machine that could combine these two capabilities. RIZE’s patented hybrid Augmented Deposition process solved this problem, simultaneously extruding engineering-grade thermoplastic and jetting functional inks precisely where they are needed in the part. Airflow Chamber Apparatus One recent application where SI2 used their RIZE ONE 3D printer was to produce an end-use airflow controller for an airflow chamber apparatus. The apparatus [...]

3D Printing Unlocks Consumer Personalization

Razor manufacturer Gillette is piloting its Razor Maker™ concept—a platform that serves as one of the first examples of direct-to-consumer, end-use 3D printed parts. Using Formlabs Form 2 3D printers as its production engine, Razor Maker™ gives consumers the power to create and order customized 3D printed razor handles, with the choice of 48 different designs (and counting), a variety of colors, and the option to add custom text. “Our partnership with Formlabs, and the power of their 3D printers, enable consumers to have a say on how their razors should look. We are excited to work with our Boston neighbors to pilot this breakthrough concept of customization,” said Donato Diez, global brand manager for Gillette and Razor Maker™ co-founder. Unlocking Design Freedom and the Power of Personalization The Razor Maker™ concept unleashes design freedom from designer’s desk to final product, and offers a glimpse into the future of mass-customized products. “Combining our best shaving technology with the power and flexibility of 3D printing opens up a whole new world of product design possibilities,” said Rob Johnson, design engineer and Razor Maker™ co-founder. With 3D printing, complexity and variety are “free”; a 3D printer takes no more time, energy, or material to manufacture [...]

Happy Thanksgiving

We just want to take this opportunity to express our gratitude for our customers. Without you, we wouldn't be where we are today. We sincerely hope you enjoy this special time of year. Happy Thanksgiving to you and yours. Please note that Cimquest will be closed this Thursday and Friday. We will be back to business on Monday, November 26th.

RIZE Announces New 3D Printing Materials

RIZE has enhanced the value of their RIZE ONE 3D printer by providing a compelling range of new materials, including carbon composite, to enable a new set of industrial applications. The current materials, RIZIUM™ ONE White and Black are already demonstrating their value in delivering strong and safe parts for functional prototyping, jigs, tools and fixturing and end-use service parts. RIZE recently added RIZIUM™ CARBON and will release an additional material called RIZIUM™ ENDURA in 2019. RIZIUM™ CARBON is based on an engineering-grade thermoplastic, reinforced with carbon fiber for a higher modulus and incredible visual finish. RIZIUM CARBON is ideal for applications such as functional prototyping for manufacturing. RIZIUM ENDURA, for its part, is a fiber-reinforced filament that offers high accuracy printing and high impact strength. RIZE says the new material is well suited for producing large functional parts. Notably, RIZIUM ENDURA is compatible with the XRIZE’s full-color inks. For more information about the RIZE products, their current promotion and more details on the new materials, please click the button below. More info