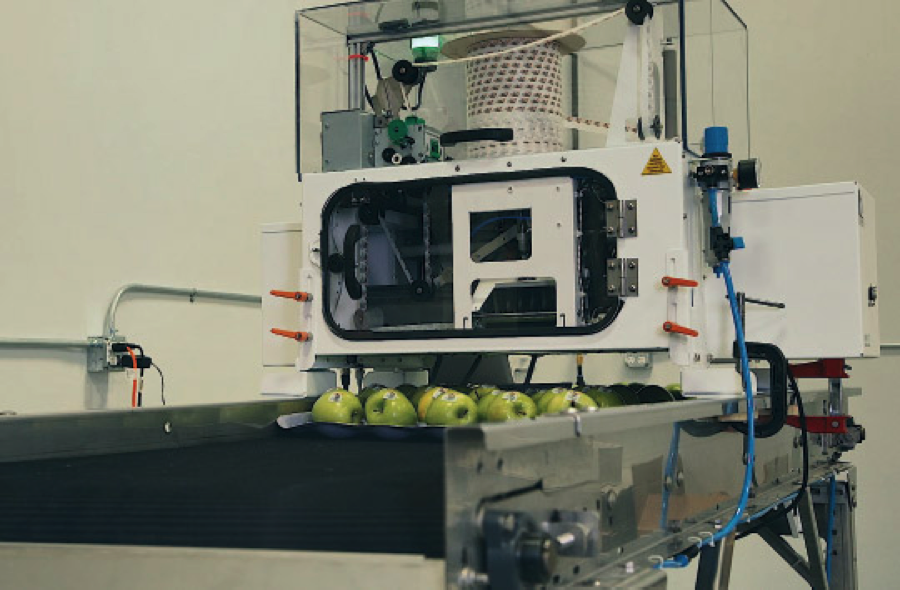

HP Multi Jet Fusion 3D Printing Streamlines Machinery and Production Lines

The rules of the game are changing Machinery and production line component production have typically been served with traditional processes such as CNC machining and injection molding. However, as industries strive to find greater efficiencies and add more value for their customers, machinery and production line manufacturers and runners are looking for ways to enhance and optimize how they produce components–in order to offer unique/customized solutions at low cost to their internal or external customers, drive greater production line efficiencies with lightweight, high performance parts, and maximize equipment uptime. Why consider 3D printing for machinery parts? 3D printing opens up a world of new opportunities for machinery and production line component production–both for original and spare parts. HP Multi Jet Fusion is a relatively new 3D printing technology that powers HP’s Jet Fusion 3D printers, which can offer disruptive cost, speed, and quality benefits compared to other 3D printing technologies: Speed HP Multi Jet Fusion can help minimize machinery and production line downtime and associated costs thanks to the production of customized original and spare parts in-house, reducing lead times from weeks or days to a matter of hours versus existing production methods. In-house, on-demand production of multiple new part designs in parallel [...]

RIZE 3D Printer Peel-Away Support

It is very fast and easy to remove supports with Rize 3D printing. This gets you to a functional part two times faster and for a fraction of the cost of other technologies. Watch the video below to see for yourself just how easy industrial 3D printing can be using Rize. For more information on Rize 3D printers, please click the button below. More Info

3D Printing Accuracy, Precision, and Tolerance

This post will cover some of the fundamental concepts in 3D printing: accuracy, precision, and tolerance. Understanding these key concepts and the differences between them is necessary for achieving the level of performance you desire when evaluating any 3D printing technology. First and foremost, you need to understand that just because a printer lists a high-resolution in a spec-sheet, it does not mean that your parts will be accurate or precise. This is a common misconception and will be covered in a future blog post. Let’s begin by defining the three terms (accuracy, precision, and tolerance) and then we will use common examples to help you understand each. Accuracy is how close a measurement is to true-value. A common example is a target where the true-value is the bullseye. The closer you are to the bullseye, the more accurate you are. In 3D printing, the true-value equals the dimensions of your CAD model and how close the 3D print lines up with those dimensions. Precision measures the repeatability or consistency. For example, your shots on a target could be hitting near the same spot every time but not necessarily on the bullseye. In 3D printing, this translates into reliability, i.e. will your printer [...]

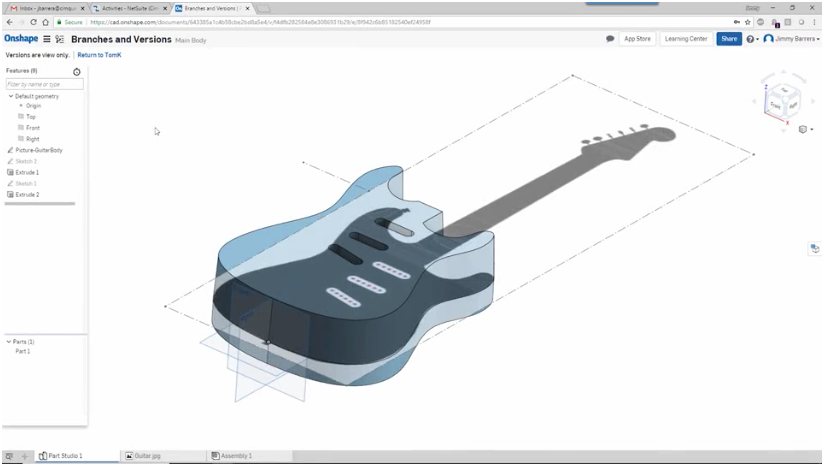

Onshape Branching and Versioning

One of the challenges in product design is in keeping the brainstorm workspace organized. You will probably explore many “what if” scenarios to come up with a good starting point for the product and Onshape has a great design and collaboration solution for this called Branching and Versioning. In this example, we are looking for a creative guitar face for the guitar we are designing. In order to leverage our colleagues' creativity, we first need to Create a version. This captures a snapshot of your design in time. Having that, you can then leverage the Branch functionality and branch off to a workspace to experiment in without affecting the original design. We've created several branches springing from the Base Version. Each of our colleagues now have their own workspace to brainstorm in independently. Once everyone has had a chance to experiment in their own workspace, you can quickly cycle through what everyone came up with. Onshape also lets you compare Versions, Workspaces, or even moments in History in a Part Studio. If there is one particular design that you would like to implement, you can choose to Merge it back to the base version and continue designing from there. As you can see, [...]

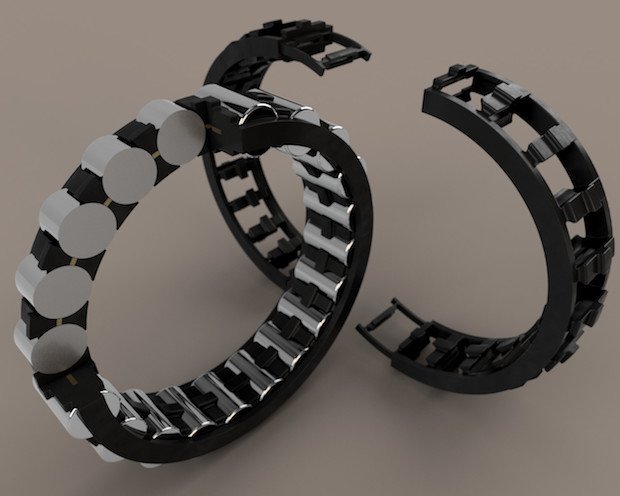

Multi Jet Fusion Used by Bowman International

Rollertrain bearing cage, manufactured with HP's Multi Jet Fusion technology. Bowman International has revealed more details on its investment in HP’s Multi Jet Fusion (MJF) 3D printing technology for the manufacture of bearings, seals, and cages. The company mentioned its acquiring of MJF technology after it announced it had implemented AMFG's automation software last month. Supplied by Europac3D, Bowman has purchased the 4200 platform to help reduce on costs and time, while increasing the functionality of end products. It is also the first MJF machine in the UK to print parts in PA11 nylon, which can help deliver parts with greater elasticity, durability and functionality. Bowman has used the MJF technology to produce a bespoke ‘Rollertrain’ cage, which boasts an interlocking structure which uses the rolling elements to pin together each section of the cage. Thanks to its design, there is now enough additional space around the cage’s circumference to add two-four more rollers than other bearing cage products on the market, meaning the load can be spread over a higher number of rolling elements, and performance can be enhanced. With an apparent 70% increase in the load bearing capacity of its split bearings and an increased work life of up to [...]

How to Debind Desktop Metal Studio System Parts

In the video below, Desktop Metal demonstrates how to load parts and set up a job for solvent debind in the Studio System debinder. For more information on Desktop Metal 3D printers, please click the button below. More info