Reverse Engineering a Can Holder

We reversed Engineered this 6-pack can holder which is great for quickly snapping cans on to it and easily carry them around. Here’s a brief overview of how we reverse engineered it, improved the design, and then optimized it for injection molding. First, we used 3D System’s Capture scanner to scan directly into Geomagic’s Design X. With a resolution of .110 mm, and an accuracy of .060 mm, we were able to capture even the finest details. Since the base geometry is patterned, we just needed to ensure that we capture enough geometry of one can holder and then we used CAD to pattern the other 5 holders. With Geomagic’s Design X we are able to interrogate our scan and trace the outline of each feature that we needed in order to recreate the sketches and features in our CAD file and then check the deviation between our CAD model and the original scan data. When done, we did a “Live Transfer,” meaning we exported the feature tree out to our CAD software. This allowed us to make modifications to the design as if it was natively created in CAD. We were able to leverage this and strengthen the areas that had failed [...]

Rize 3D Printing in Life Sciences

Life Sciences, in this case, the pharmaceutical and medical device sectors, have various applications in which 3D printing can contribute real value. The needs are very specific and there are a few crucial requirements: In clinical applications, all of these requirements hold true. But what's more is that the printer must be safe to use and parts must be able to be sterilized. For medical devices, parts must also be very strong so they can be used in functional settings. The Rize One provides a safe and secure solution the Life Sciences. The patented ADP process creates near isotropic parts, with minimal post processing and zero Volatile Organic Compounds or VOCs. In this case study Conmed, a global medical device manufacturer, had a need for parts with great surface quality, strength and markup. Using Rize they were able to first create functional prototypes, followed by molds for pouring silicon and low-temperature plastic. After realizing the possibilities, they expanded their use of the Rize to create end-use replacement parts: handles, other parts of assemblies, and tooling. An added benefit of the Rize is in its ability of jetting marking inks, which allows Conmed to efficiently trace parts in their inventory. Aside from Medical Devices, [...]

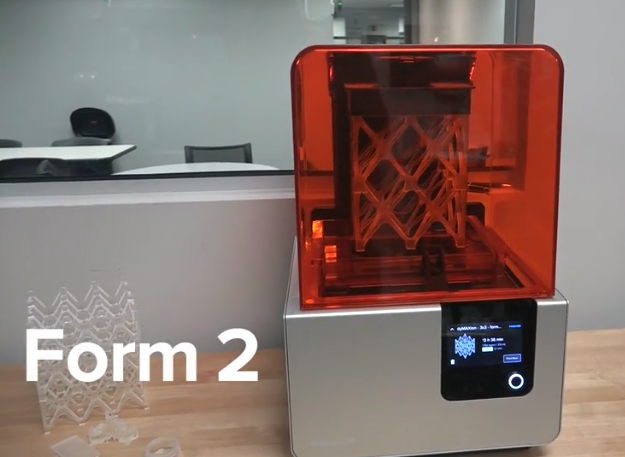

Form 2 Engineering Materials

The Form 2 3D printer offers professional-level 3D printing at a lower barrier to entry relative to industrial SLA machines. It is capable of producing detailed models with smooth surface finish, making it a sound solution for iterative prototyping, fixtures and manufacturing tooling. The Form 2 currently has 6 engineering grade materials in its portfolio, each with their own unique characteristics and benefits and they include . . . • Grey Pro Resin is a versatile material great for concept modeling and functional prototyping. It offers high precision with moderate elongation and low creep. • Rigin Resin is a glass filled resin that offers very high stiffness. Great for printing thin walls and features, it is highly resistant to deformation over time and provides a polished finish. • Durable Resin specializes in low friction and wear, making it ideal for bearings, ball & joints, and snap-fits. It offers smooth glossy finish and high resistance to deformation. • High Temp Resin has the highest heat deflection temperature of 289 C and can be used for models with environmental testing, or molds for casting and thermoforming. • Flexible Resin is best used for parts with ergonomic features that bend and compress. It can simulate soft-touch [...]

Formlabs Introduces Ceramic Resin and Changes Everything

Formlabs formally recently announced a new ceramic resin for the Form 2 3D printer. This is a notable departure from their traditional materials, which have up to now been various types of photopolymers. While they’ve marketed strong, flexible and colorful materials, they’ve never released a ceramic resin, until now. Ceramic 3D prints are highly desirable in a number of situations, and are produced in quite a different manner. The Form 2’s normal photopolymer process simply involves solidifying the liquid resin with a laser and curing the completed print in a UV bath, ceramic processing requires different steps. Formlabs explains that the ceramic resin is first 3D printed in the same manner, although they do provide a number of tips to ensure a more reliable result, such as adjusting designs to fit within ceramic tolerances and roughening the build platform for extra special adhesiveness. The differences are after the print completes. The “green” part is removed from the Form 2, and supports are trimmed off. There is no need for further UV curing, as the print then is placed in a ventilated kiln. I should point out that Formlabs does not supply a kiln, and you should be able to find one from many [...]

Jewelry Customization with 3D Printing

Founded in 1933, leading German wedding ring manufacturer egf Manufaktur is shortening the feedback loop between designer and customer tenfold, blending a custom software solution with desktop digital fabrication to create a modern, highly personalized customer experience. “Every wedding ring is individualized and made-to-order. They’re more important than any other jewelry product in showing the customer’s individual ideas,” said Nick-Maximilian Binder, assistant to the managing director at egf, and leader of the on-site 3D printing project. “That's why it only makes sense to configure a ring in CAD software, print in 3D, and give it to the customer before the ring is hand-crafted by the goldsmith. We find that customers want to modify the original ring to make it either thicker or narrower, or with varying stone settings.” Egf was awarded the quality certificate of the Jewelry Technology Institute of the University of Applied Sciences Pforzheim. To get up and running with little experience in 3D printing, egf turned to Formlabs Form 2 desktop 3D printer. “The Form 2 excited us the most with its speed—less than one hour for printing our rings, the high quality its resins, and ease of use,” Binder said. The company customized their CAD software so that employees, seated [...]

Making Additive Manufacturing Sustainable and Inclusive

Rize recently hosted a live Webinar called "How to Make Additive Manufacturing Sustainable and Inclusive." The goal of this webinar was to help users of additive manufacturing better understand how to drive increased sustainability and inclusivity in their manufacturing operations and why that’s so important. The discussion focused on how Rize’s patented Augmented Polymer Deposition (APD) hybrid process enables sustainability and inclusivity by providing the highest part strength, the fastest time to a functional part and a safe and sustainable working environment. You can watch a recording of this Webinar by simply clicking on the image below. For more information on the Rize One 3D printer, please click the button below. More Info