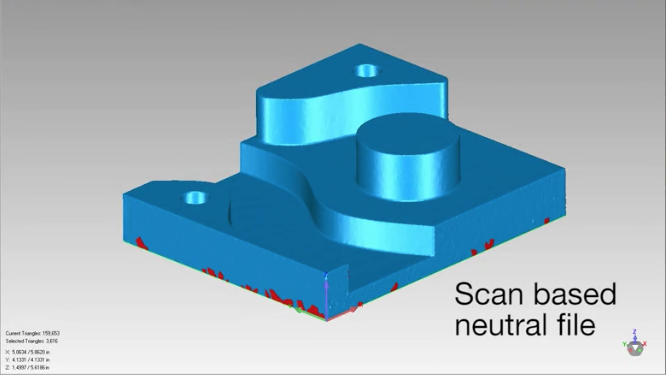

Differences Between Scan-Based and CAD-Based Neutral Files

Scan-based files involve cleaning up the scan, optimizing the mesh quality, and ensuring that the scanned mesh is watertight. At this point we can generate the neutral file based on this processed scan data. CAD-based is bit more labor intensive. It involves interrogating the mesh, creating CAD sketches and CAD features and fitting them to match the scanned data. Once the scanned data has been recreated as CAD data, we can then generate the neutral file based on the final CAD geometry. Let’s analyze the differences between the two. The main difference between these two approaches is that a CAD-based neutral file is able to preserve the true geometric features of the scanned part. This means that a cylinder would remain a true cylinder. The same would apply for planar faces, cones, and spheres. This would allow you to create and leverage construction geometry, such as planes, axes, and faces. Being a true CAD shape, any sharp edges on the original part would also be preserved. In summary, if you are looking to preserve geometric features, use the file for 2-axis machining on prismatic parts, or plan on modifying a neutral file in CAD, a CAD-based neutral file would be the best option. [...]

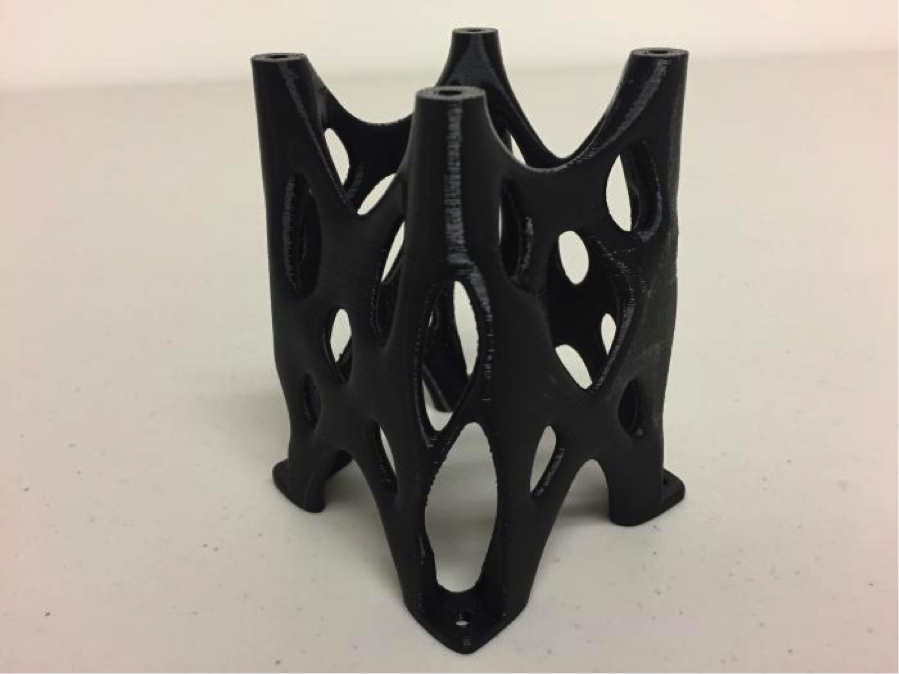

Rize Launches Rizium One Black Material

Rize recently announced the immediate availability of their new Rizium™ One Black material. Like their existing Rizium One material, Rizium One Black provides mechanical properties that mimic injection molded plastic parts, including isotropic strength. The parts are also watertight, have a high HDT, can be sterilized and provide chemical resistance to acid, acetone, alcohol and more. In addition, parts made with Rizium One Black provide the same zero-post-processing capability as parts made with Rizium One, for fast, easy, clean and safe support removal with your hands immediately following printing. Rizium One Black is also safe and recyclable, so you can produce functional black parts in an office, tool room, on the production floor or in the field. Whether you use Rizium One or Rizium One Black for your functional parts, Rize’s APD additive manufacturing redefines the user and customer experience to scale the technology to an entirely new segment of commercial and industrial users. For more information on Rize 3D printers, please click the button below. More Info

Custom Earbuds Manufactured With 3D Printing

repost from www.formlabs.com Judging by most mass-produced products on the market today, you’d think humans come in just three sizes. We don’t. So why don’t the products we buy reflect that? Custom products perform better and consumers embrace them, but custom manufacturing is often not economical. Collecting personalized data from consumers is tricky, custom tooling is expensive, and tracking customized parts from initial order through production and shipping is complex. 3D printing is changing everything. Falling costs and innovation in materials have made 3D printing practical for manufacturing—and promise to bring the dream of mass customization into reality. Economically Manufacturing Custom Products Tailor-made items perform better, plain and simple. A truly custom-fit earbud can provide unparalleled long-term wear, comfort, stability, and noise reduction. Advancements in scanning technology paired with accessible, high-quality 3D printers make it viable to manufacture custom earbuds and other audiology products at scale. Manufacturing with 3D printing makes producing on-demand custom earbuds a reality. Though it’s not a silver bullet, 3D printing removes many of the challenges traditionally associated with mass-producing custom products: 3D printing is a zero tooling production process–there’s no need to produce thousands of the same item to recoup the initial cost of molds. Complexity [...]

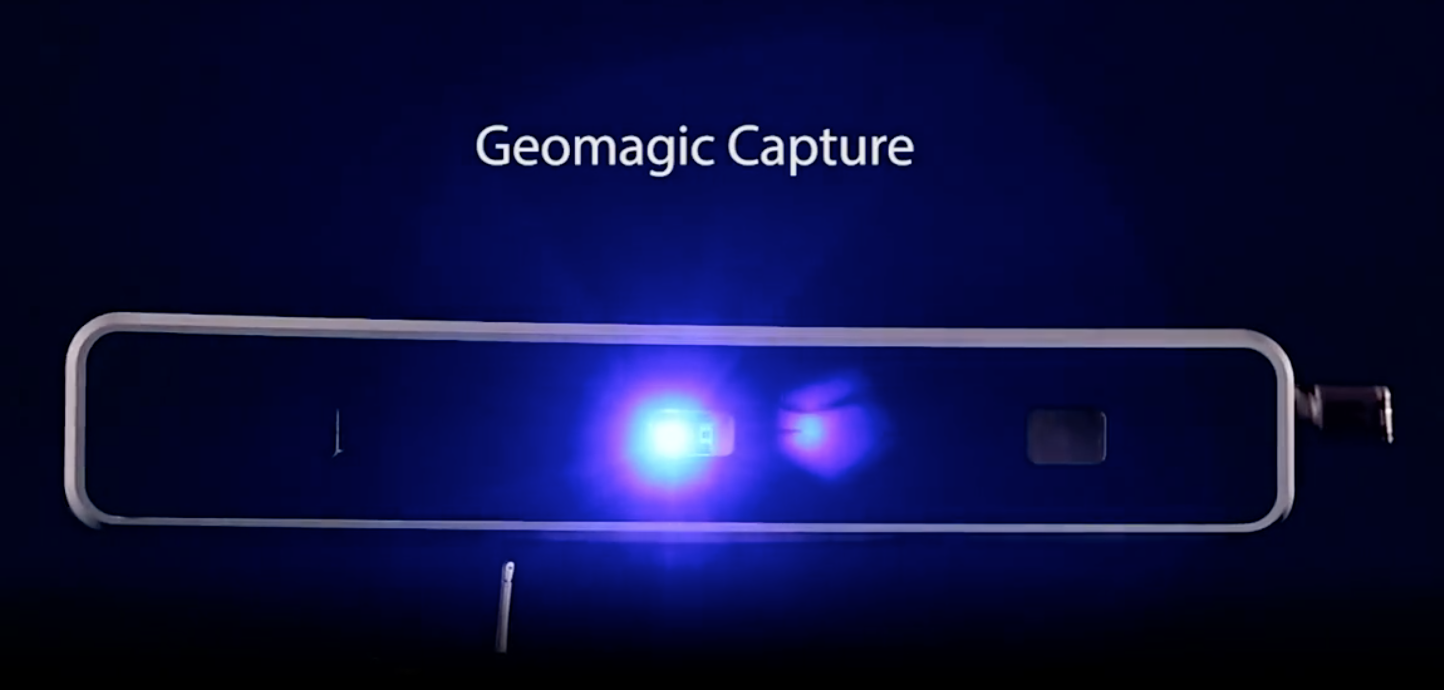

Geomagic Capture Scanner

The Geomagic Capture Scanner is an industrial grade scanner that can be used for both reverse engineering and inspection. It allows you to bring physical parts into CAD for the purpose of reviving a lost design, developing entirely new products, or inspecting existing parts. Let's take a look at some of its key features. The Geomagic Capture is a blue light scanner offering fast and accurate scanning in a portable, lightweight unit. This device can hold accuracies of +/-.0035" and is very simple to set up and use. The Capture scanner connects to the PC through an Ethernet port and the turntable requires a USB connection. All of the Geomagic software products synchronize the turntable with the scanner to register or align adjacent scans, producing perfectly aligned complete mesh models for various downstream applications. The Capture Scanner is a great tool for companies looking to get products to market faster. Let's say you have an older physical part with no design data or drawings. With the Capture, you can acquire the data, process it, and then bring it into CAD in order to make modifications to the original design. You can digitally restore the old physical part, similar to converting a vinyl record [...]

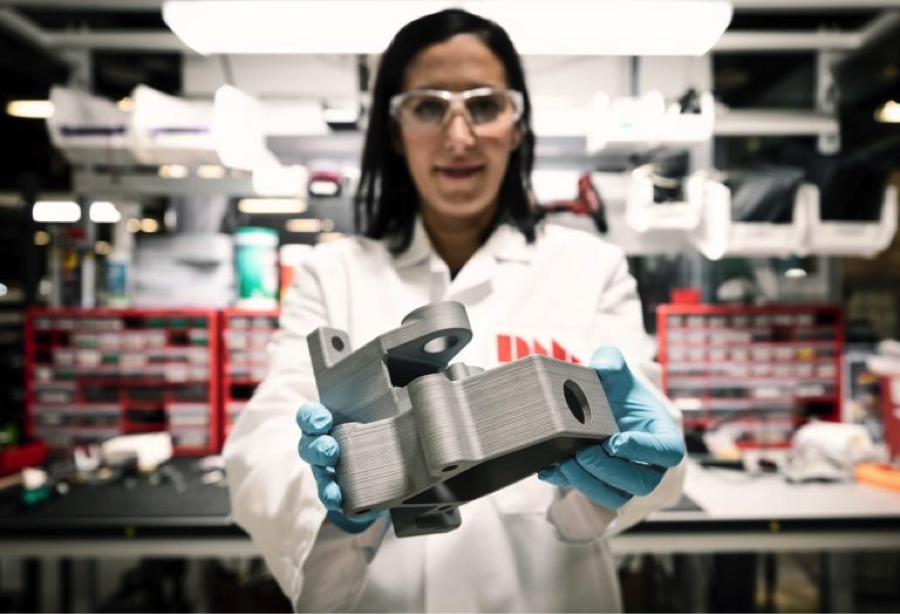

Desktop Metal Receives Two Patents for Removable 3D Printing Support Technology

Reprint from https://3dprint.com It hasn’t yet been a year since Desktop Metal announced the release of its two metal 3D printing systems, the DM Studio System and the DM Production System. Investors and others had been eagerly anticipating the introduction of the startup’s new technology, and they weren’t disappointed, as the Studio System and Production System looked right away to be impressive developments. The Studio System was described by Desktop Metal as the first office-friendly metal 3D printing system, featuring a 3D printer, a debinder, and a sintering furnace that fit neatly into an office or workshop. It also introduced Bound Metal Deposition (BMD) 3D printing technology, a powder-free technology that involves the extrusion of rods of bound metal. It’s safer and easier than other types of metal 3D printing technology, with support structures that can be removed by hand. The Production System is the first metal 3D printing system to be designed for mass production. It too introduced a new 3D printing technology: Single Pass Jetting (SPJ), which is capable of 3D printing parts 100 times faster than laser-based 3D printing systems. The Production System is capable of 3D printing at a rate of 8,200 cubic centimeters per hour and is the [...]

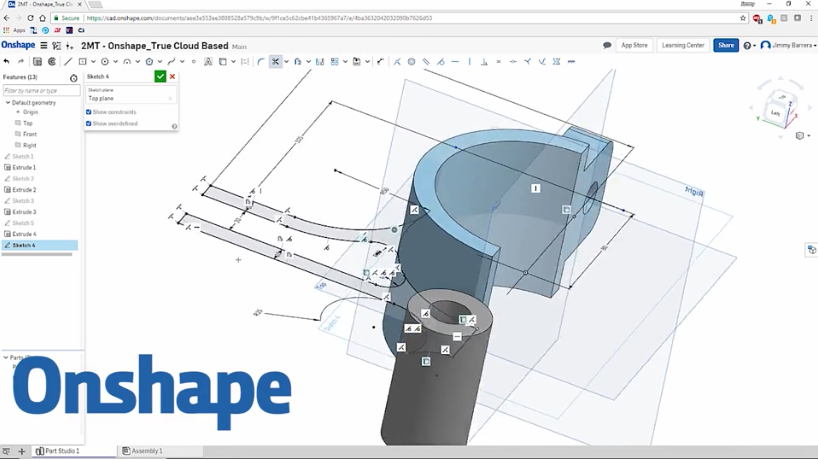

Onshape Cloud-Based CAD

Today we are going to introduce Onshape, the first full cloud-based professional 3D CAD system. Onshape has built a 3D professional CAD system and placed it on the cloud instead of tying it to a PC. Why is this so revolutionary, and what are the advantages to this? First, and probably the biggest, you don't have to install the software. Being fully cloud-based, all you have to do is log in via any web browser and you have full access to the latest 3D CAD software release. In addition, updates and patches happen automatically, behind the scenes. This means no IT support required and no software administration headaches. Another advantage is that CAD along with your "working files" are accessible from virtually any device since everything resides in the cloud. Whether you log in via your PC, tablet, or phone, you have full access and can make the needed changes right there and then. No need to wait until you get back to your office PC to make simple changes! Lastly, full cloud-based CAD runs on and stores data on multiple redundant servers. If one has an issue, the other server kicks in and takes over, so that your Onshape session is uninterrupted. [...]