Employee Spotlight – Genise Postell

In today’s Employee Spotlight we are featuring Genise Postell, the Senior Office Administrator here at Cimquest. Here’s a little information that will help you get to know her a little better . . . What are your responsibilities at Cimquest? My main responsibility is to process Mastercam maintenance renewal orders and 3D printer orders. What industry do you come from? I have worked in a few different industries: restaurant, architectural, landscape, retail, hotel, etc. Where are you from (hometown)? Old Bridge, NJ What is your educational background? After high school, I graduated from the Executive Assistant program at Katharine Gibbs How long have you worked at Cimquest? 14 years What are your hobbies? I am a football and baseball mom What do you enjoy most about your job? I get satisfaction out of making sure our customers are happy with their Cimquest experience. What do you feel is the most important aspect of your job? Making sure orders are placed accurately and efficiently What is your most treasured possession? My children Do you have any hidden talents? Just a little twin telepathy. I have a twin sister who is 1 minute older than me. What is the craziest thing on your bucket list? Indoor [...]

Employee Spotlight – Tom Kryger

In today’s Employee Spotlight we are featuring Tom Kryger, an Applications Engineer here at Cimquest. Let’s get to know Tom a little better . . . What are your responsibilities at Cimquest? Application Engineer. What industry do you come from? Manufacturing Where are you from (hometown)? Phillipsburg, NJ What is your educational background? High School, Technical How long have you worked at Cimquest? 2 Years. What are your hobbies? Fishing, outdoors, and making things. What do you enjoy most about your job? Instructing. What do you feel is the most important aspect of your job? Customer satisfaction. What is your most treasured possession? My family Do you have any hidden talents? Metalworking What is the craziest thing on your bucket list? Parachuting What is your favorite meal? Lasagna Where is your favorite place to vacation? Near water What is the best advice you have ever given or received? Set an example. What is your favorite movie? Matrix What is your greatest fear? Rats Who is your favorite celebrity? I like the ones that give back to society. When you were young, what did you want to be when you grew up? Fireman or a soldier Stay tuned to future blog posts when we [...]

SolidWorks 2018 UI Enhancements

SolidWorks 2018 is now out to the public so let’s take a look at five new enhancements that will allow you to get better acquainted with the User Interface of this release. Right off the bat, when you start up SolidWorks, you’ll notice that there is a new Welcome Dialog Box. It’s a one-stop shop for functionality that used to be found in the Task Pane. For example, the Home tab allows you to open new or existing documents, browse recent documents or folders, and even access SolidWorks resources. The additional tabs provide links to Tutorials, Sample Files and MySolidWorks Training, Certification, and even technical alerts to help you stay current. The second enhancement has to do with Mouse Gestures. Not only do you have many more options as to the number of commands available in the mouse gestures wheel, but it’s also easier to customize with the new Mouse Gestures Guide. Third, let’s talk about the Measure Tool. Some of the enhancements here include the Input Box now supporting 6 items, instead of just 3. There is also a new function called Quick Copy, which allows you to copy a value from the dialog box, and paste it at a required location. [...]

Desktop Metal Studio Solution

Additive Manufacturing of metals originated in the early 1990's through a process known as direct metal laser sintering. This process uses laser toolpaths to weld powdered metals into three dimensional parts. While effective, the technology has major barriers to entry due to the volatile nature of metal powders. These powders are reactive and can cause fires, requiring significant investments in infrastructure, including explosion proof rooms, respirators, and not to mention highly specialized operators. All of these requirements result in a high startup cost that can discourages widespread adoption of the technology. With the Desktop Metal Studio Solution, many of these traditional obstacles are eliminated. The solution is the first office-friendly metal printer and it is similar to the safest, most widely used 3D printing process, FDM. Let's explore the process: To begin, a digital model is prepared. The file is sent to the machine and the printer extrudes rods that have metal powder bound within wax and plastic in a process called Bound Metal Deposition or BMD. The resultant part is known as the "green part". In the next phase, the part is submerged in a solution to remove wax from the bound material. It is then placed in a microwave-enhanced furnace, which [...]

HP Multi Jet Fusion – Transformative 3D Printing Technology

HP brings decades of experience in 2D printing and materials science to the 3D printing market. With the development and release of this platform, they seek to address the demands for increased speed, throughput, and productivity in additive manufacturing. The HP Jet Fusion 4200 is made up of the printer, build unit, and processing station. To begin, HP material cartridges are first inserted into the processing station. The station performs an automated mixing process, and the materials are loaded into the 3D Build Unit. The build unit is now ready to be placed into the printer. In the printing stage, a layer of material powder is first spread across the build area. In one continuous pass, fusing and detailing agents are applied, along with energy to further fuse the layers. The build area then moves down a layer and the loop is repeated until the parts are complete. Upon completion of this stage, the build unit is removed and placed in the processing station to cool. A second build unit can then be inserted back into the printer for the next build. The HP Multi Jet Fusion has a closed loop thermal control system, which measures hundreds of points on the material bed. [...]

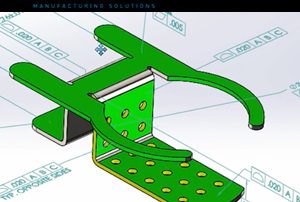

Using SolidWorks PMI for Final Inspection

Let’s discuss two pieces of software that work really well together in the 3D part inspection world: SolidWorks, and Control X. SolidWorks is one of the leading CAD tools in today’s design and manufacturing world. One of its advantages is that it offers you the opportunity to create a 3D annotated model. This can include things such as explicitly-specified dimensions, tolerances, 3D GD&T, surface texture symbols, finish requirements, and so on. This 3D annotated model is then used to manufacture the part, as well as provides the needed criteria to inspect the part. A part can contain anywhere from several dozen annotations, to several hundred! Wouldn’t it be great to repurpose these annotations, and import them directly into the inspection software, as opposed to recreating all of them one by one? Well, one of the inspection software packages that have this ability is Geomagic Control X. The first step is to add all of the 3D annotations directly to your 3D model. This is a pretty simple process in CAD. Once this is complete, you can open up Geomagic Control X, and use the PMI Wizard to import the 3D annotated model. All of the explicit dimensions and GD&T information come through just [...]