Introducing Design X Essentials for Mastercam Users

Attention Mastercam Users Who Need To: Design machinable parts from point clouds or mesh files. Have access to incredible sketching, solid and surface modeling CAD tools. Machine parts when no drawing or model exists. Repair broken parts where no CAD model or Drawing exists. Introducing Design X Essentials for Mastercam Users Scan-based Step/Parasolid files vs CAD-Based Step/Parasolid Files – What’s the difference? Some of you may have experienced the nightmare of attempting to create good quality G-Code by programming Step or Parasolid models that originated from “Auto-Surfaced” scanned data. I affectionately term these “Scan-Based Step (or Parasolid) files” and they are functionally useless when trying to produce good quality pocketing, profiling, point-to-point or other simple toolpaths. With these models, circular interpolating a bore with an end mill doesn’t create a single G02 or G03 block but rather, hundreds or even thousands of G01 points are generated, providing a gigantic, inefficient point-to-point G-Code program. But what if there was a way you could create “CAD-based Step (or Parasolid) files” from point clouds or mesh files where the models react as if the were generated by a CAD system? Well now you can! Cimquest Mastercam users can purchase Design X Essentials at a 40% discount [...]

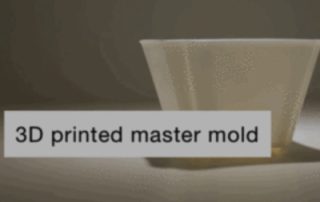

Ceramic Production Innovation via 3D Printed Prototypes

Artisans are increasing speed, reducing costs, and expanding flexibility by using 3D printers to create prototypes as opposed to traditional hand-made models. Chinese porcelain has always been loved by people all over the world for its unique beauty, among which the Southern Song Dynasty official kilns are very popular because of their elegance. Xiao Heqing, a ceramics manufacturing expert, inherited traditional ceramic skills and introduced 3D printing in the process of making porcelain from the Southern Song Dynasty official kilns to speed up the production process. The new Southern Song Dynasty official kiln porcelain production process is complex, and 3D printing changes the process for the first step, mold making. Mold-making directly affects the shape of porcelain molding and the quality of porcelain. It is mainly divided into two steps, making the master pattern and turnover the mold. Traditional mold-making method The traditional mold-making method is based on the master pattern and plaster casting technique. The master pattern is made by cutting and trimming the clay and this clay mold is turned over with plaster to make a production mold. Challenges The making of clay molds is complicated and tedious, so it takes a lot of time to make a complete master mold. [...]

Which 3D Printing Metal Technology is Right for You?

If you are interested in learning more about 3D printing Metal, please join us this afternoon for a special webinar where you will learn which metal technology is right for you and how easy they are to adopt. 3D Metal printing can be transformational - unlocking new design freedoms for part innovation with fast iterations and enabling tooling-free production of spare parts or custom fixtures. When getting started with the technology, it’s important to understand the different technologies available to make sure your investment fits your production workflow and your company gets the best ROI. Today, June 28th at 2:00 PM EST, Desktop Metal's Sean Roberts, will give a breakdown of two of the easiest-to-adopt metal additive manufacturing technologies, “powderless” Bound Metal Deposition (BMD) and the easily scalable binder jetting. In this webinar, you’ll: Learn the processing workflow for both extrusion-based 3D printing processes and metal binder jetting, including sintering, used with both technologies and how software-based workflows help ensure easy-adoption success Gain an understanding of which technology is more suitable for different types of applications See use case and part examples from Desktop Metal’s Studio and Shop System printers Don't miss out. Register now! Register Now

Expanding Formlabs Medical Materials Library

Formlabs Healthcare is introducing BioMed Durable Resin for strong and impact-resistant medical devices and instruments. The BioMed Resin family is targeted for a wide range of healthcare applications, helping advance 3D printing for medical devices and point-of-care manufacturing and providing new possibilities for the wider healthcare community. BioMed Durable Resin is a clear material for biocompatible applications requiring impact, shatter, and abrasion resistance. This USP Class VI material is made in an FDA-registered, ISO 13485-certified facility and can be used in applications for long-term skin and short-term tissue, bone, and dentin contact (<24 hours). BioMed Durable Resin would be a great solution for: Patient-specific instruments Single-use instruments End-use devices and components requiring biocompatibility and impact resistance Learn More

Xtreme 8K Lets you Expand Your 3D Printing Capabilities

ETEC Xtreme 8K 3D Printing Material Will Expand Your Printing Capabilities As new 3D Printing materials expand, so does Additive Manufacturing’s ability to solve more production applications. Having a printer that can do it all is challenging because there is no one best-fit technology. However, ETEC’s Xtreme 8K solves many problems: It has a heated vat that allows users to process a wide variety of highly viscous materials including hard plastics, high-temperature plastics, elastomers and rubbers. Some great examples are Elastic ToughRubber™, which is perfect for shoe midsoles and heel cups, seals, door boots, bellows, foam-like lattice structures and impact parts. It also prints in Soft ToughRubber™ which prints parts that are soft, flexible and functional silicone-like with fine print feature detail. The Xtreme 8K’s innovative, top-down printing method eliminates the peeling step required in traditional DLP, as well as fewer supports. This allows the Xtreme 8K to deliver exceptionally fast print-to-part speeds. The Xtreme 8K also features the largest build volume of any production-grade DLP printer. This allows you to print everything from very large parts to thousands of small parts in a single build. The ability to produce many parts or very large parts in specialty engineering materials at extremely fast [...]

A MIM-Based Approach to Metal 3D Printing from Entry to Production: Session 4 – Desktop Metal

A MIM-Based Approach to Metal 3D Printing from Entry to Production: Session 4 – Desktop Metal Replayed from a live webinar held on June 8, 2023 Check out the fourth of our 4-part webinar series, A MIM-Based Approach to Metal 3D Printing from Entry to Production. This time we were joined by Desktop Metal! During this webinar, we explore the benefits of the Studio System, and demonstrate how it can help you streamline your process, reduce costs, and enhance your overall workflow. We also showcase several customer applications and success stories, highlighting the diverse range of industries and use cases that have already benefited from the power of the Studio System.