How To Choose the Right 3D Scannner

The world of 3D scanning offers many different technologies. From free scanners that run on Smartphones, all the way up to industrial options for high precision metrology, it can be difficult to determine the best 3D scanner solution that will meet your requirements. How do you know what scanning solution is right for you? The first step is to determine the object size of the parts you will be scanning. Scanners generally have a fixed Field of View, meaning they will be able to capture a set volume of data at any given time. Next, consider what you will be using the scanner for, whether it's reverse engineering, inspection, 3D Printing, producing online assets or even AR/VR. This, in turn, will determine the minimum accuracy and resolution required. Accuracy has to do with how well the scan dimensionally conforms to the physical object. When would accuracy be important? Accuracy is extremely important for inspection applications, but far less important for Web Assets or Virtual Reality. Resolution, on the other hand, refers to a scanner's ability to pick up fine detail. You can think of the density of a point cloud captured as the resolution. The closer the points are to each other, the [...]

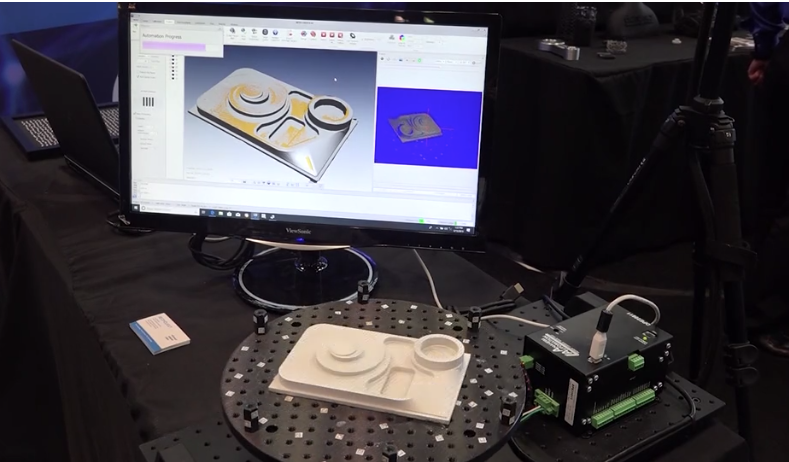

Mastercam 2020 Mill Enhancements

Mastercam 2020 Mill offers expanded machining flexibility and an increased emphasis on speed and automation. 2D high-speed toolpaths, 3D enhancements, and multiaxis features combine with dozens of additional new enhancements in a software package intended to improve shop floor productivity. Here are some of the significant highlights and new functionality in Mastercam Mill: General Enhancements Mastercam’s signature Dynamic Motion™ toolpath has been updated to streamline performance and increase programming speed. Accelerated Finishing™ receives new support for oval form and lens barrel form tools, delivering faster, smoother finishes on select surfaces. Toolpath Hole Definition has been improved, and the Features list now displays more information about the selected points, in addition to the type of selection you have made and the diameter of the selected point. 3D Enhancements Mastercam’s Equal Scallop toolpath delivers finish across sloped, curved, and flat surfaces. Now tool tip containment and “Closed” or “Trimmed” toolpath offsets deliver optimal finishes for different types of complex shapes. A new toolpath, Blend, has been added to the 3D High-Speed suite of toolpaths. Blend is based on the Surface Finish Blend toolpath but is faster and has a superior quality and includes the use of stock and holder checking. Multiaxis Improvements Deburr can use [...]

Production 3D Printing with HP Multi Jet Fusion

The release of the HP Multi Jet Fusion platform makes production 3D printing a reality, and the new Jet Fusion 5200 is on the forefront of this paradigm shift. For the first time, 3D printing was now a viable option for larger-scale production. Let's take a look at how the process works. The 5200 series features a printer, build unit, and processing station similar to the 4200 model but brings superior part predictability and reliability. For part predictability, the 5200 can be qualified to meet the process capability for a CPK of 1.33 or IT13, allowing for consistent part tolerances. To increase reliability, this system has redundancies and more robust hardware and software to complete your builds. Some examples are multiple fusing lamps and redundant motors, as well as a higher resolution thermal camera. The 5200 has a new 1-pass printing mode which gives faster building speed, without compromising on mechanical and dimensional properties. Another innovative new feature is HP's 3D natural cooling unit. Once a job is finished job it can be transferred to the natural cooling unit and then stored to cool. This frees up the build unit to be used for the next job immediately, so you can keep printing [...]

Cimquest Continues to Support the Guy E. Bourdeau Scholarship

We are proud to continue our support for the Guy E. Bourdeau Scholarship. It provides the opportunity for highly motivated students to earn the opportunity to attend the Additive Manufacturing User Group (AMUG) conference. Guy E. Bourdeau Scholars are honest, respectful, inquisitive and collaborative. The scholarship honors the memory of Guy E. Bourdeau for his dedication and contribution to the additive manufacturing industry. He was a strong supporter and advocate of the Additive Manufacturing Users Group (AMUG). The scholarship was founded in Guy’s name by his wife, Renée Bourdeau, to honor his contributions to the additive manufacturing (AM) industry. This scholarship covers the cost of participating in the 2020 AMUG Conference to be held in Chicago, Illinois, from March 22-26; this includes: Conference registration fee Access to keynote presentations, technical sessions and workshops Invitation to the Technical Competition and Innovator’s Showcase Networking breakfasts, lunches, and dinners Entrance to the AMUGexpo, Off-Site Dinner and Event Countless networking opportunities Access to mobile app, online planner and conference proceedings Exclusive AMUG volunteering opportunities with the AMUG Executive Board Accommodation at the designated conference hotel for the entire time you are in Chicago Airline ticket (Economy Class) and transportation from the airport to the conference hotel This [...]

Xpand3D 3D Printing Panel

At the recent Xpand3D event we hosted a very informative 3D Printing panel which featured an in-depth discussion on how some of the most innovative companies are incorporating 3D Printing into their manufacturing process. The presenters included Zac Holcomb, President & Co-Founder of Additive America, Jason Enos, CEO and founder of Empire Group, Jeff Guida, President & CEO of ShareRoller, David Silverstein, Manager of Rapid Prototype Lab, iRobot, and moderator Brent Ewald, Application Engineer at HP 3D Printing. If you missed the event and would like to watch the discussion, just click the video link below.

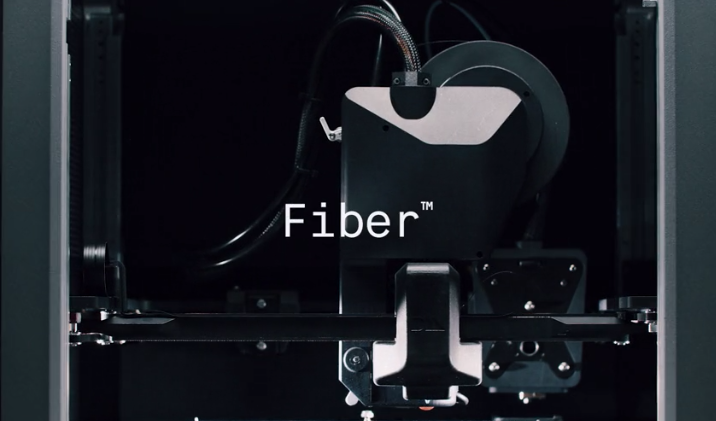

Desktop Metal New Fiber 3D Printer

Desktop Metal, the company committed to making 3D printing accessible to engineers and manufacturers, announces the world’s first desktop 3D printer to fabricate high-resolution parts with industrial-grade continuous fiber composite materials used in automated fiber placement (AFP) processes. Based on a new process called micro automated fiber replacement (μAFP), users can now print parts with a superior level of strength and stiffness, and in a broad range of materials, that traditionally required million-dollar AFP systems. This affordable new platform produces parts using materials that are two times stronger than steel at one-fifth the weight. Fiber 3D printers feature one of the largest build envelopes of any continuous fiber desktop printer. They can be purchased as individual units or arranged in print farm configurations of 6 or 10 printers. “For the first time, Fiber printers combine the material properties of high performance AFP continuous fiber materials with the affordability and speed of a desktop 3D printer.” - Ric Fulop, CEO and co-founder of Desktop Metal. Starting at $3,495 and combining continuous fiber tape with industry-proven composites, Fiber™ makes it possible for every engineer to create parts with unrivaled strength and lightness, all from their desktop. Watch an introductory video and download spec sheets and [...]